Fermenting and drying treatment device for organic wastes

An organic waste and processing device technology, which is applied in the field of fermentation and drying treatment devices, can solve the problems of cumbersome manufacturing and maintenance, complicated structure of fermentation and drying treatment devices, increased operating costs and manufacturing costs, etc., and achieves reliable and efficient fermentation and drying. The effect of suppressing operating costs and manufacturing costs, and facilitating manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, representative embodiments of the fermentation processing apparatus for organic waste according to the present invention will be described, but it is not limited thereto, and various changes can be made without departing from the gist of the present invention.

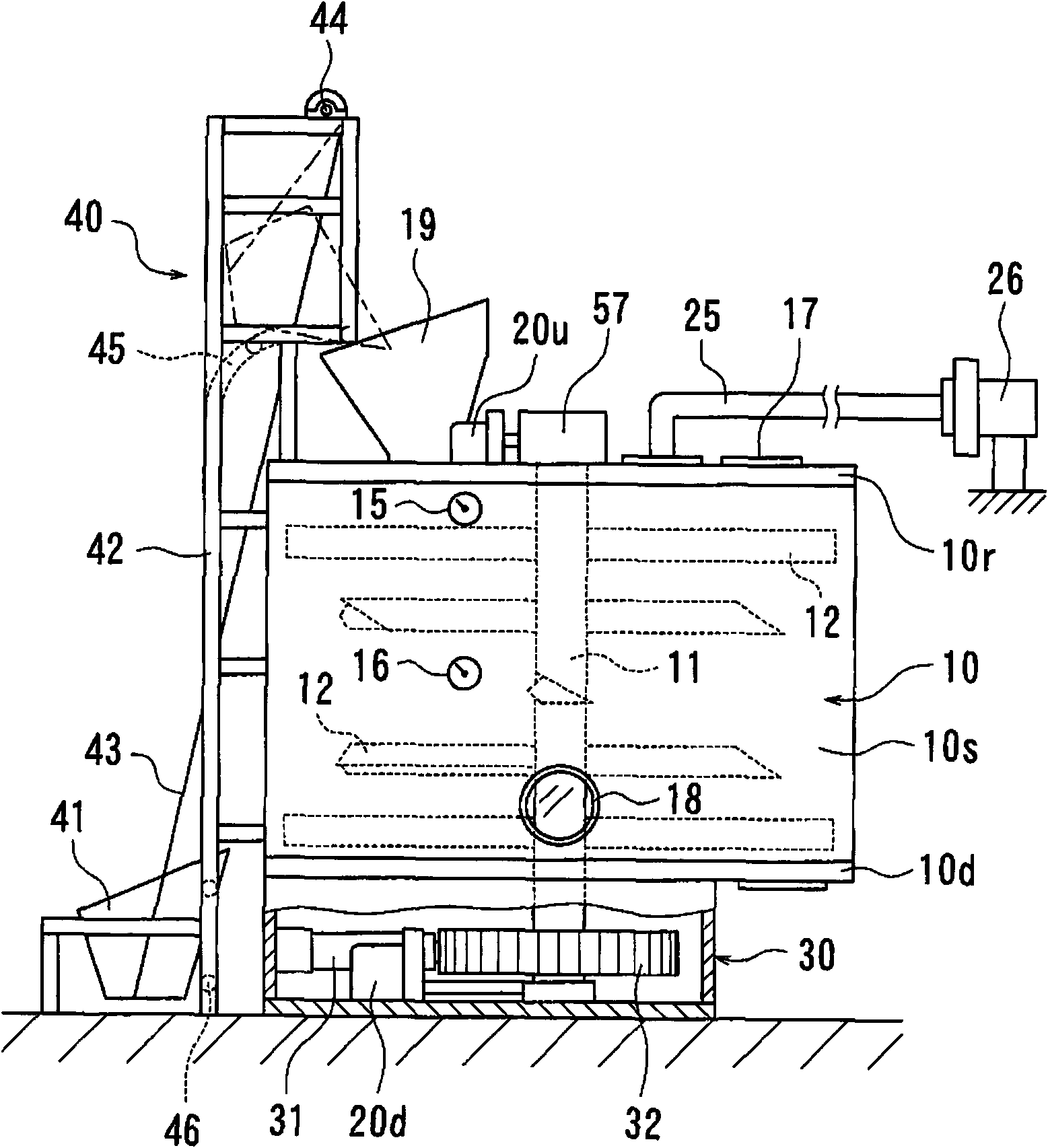

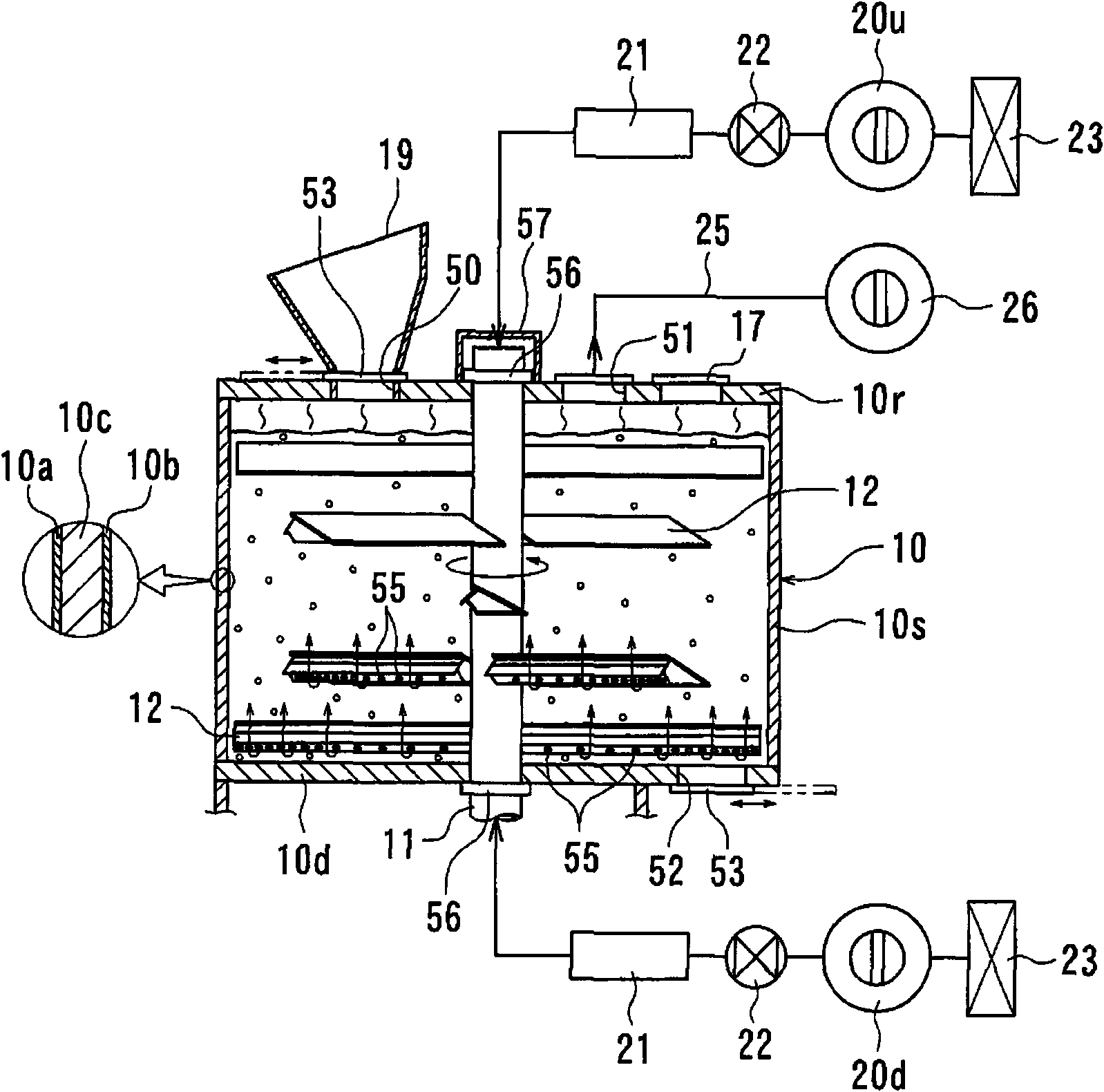

[0026] Such as figure 1 and figure 2 As shown, the fermentation treatment device has: a container 10 for fermenting and drying organic waste as the processed object, an air blower 20 for sending air into the container 10, and a machine room 30 arranged below the container 10. , and a throw-in mechanism 40 for throwing processed objects into the container 10. in, figure 1 In FIG. 2, only the mechanical chamber 30 is shown in cross section, and its internal structure is shown. figure 2 In FIG. 3 , the container 10 , which is a main part of the fermentation treatment apparatus, is shown in cross section, and the machine room 30 is omitted. In addition, piping paths are also schematically shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com