High-intensity nutation centrifugal ball-bearing mill

A centrifugal ball, high-strength technology, used in grain processing and other directions, can solve the problems of qualified powder affecting the efficiency, the life of the cone-bottom sieve surface cannot be guaranteed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

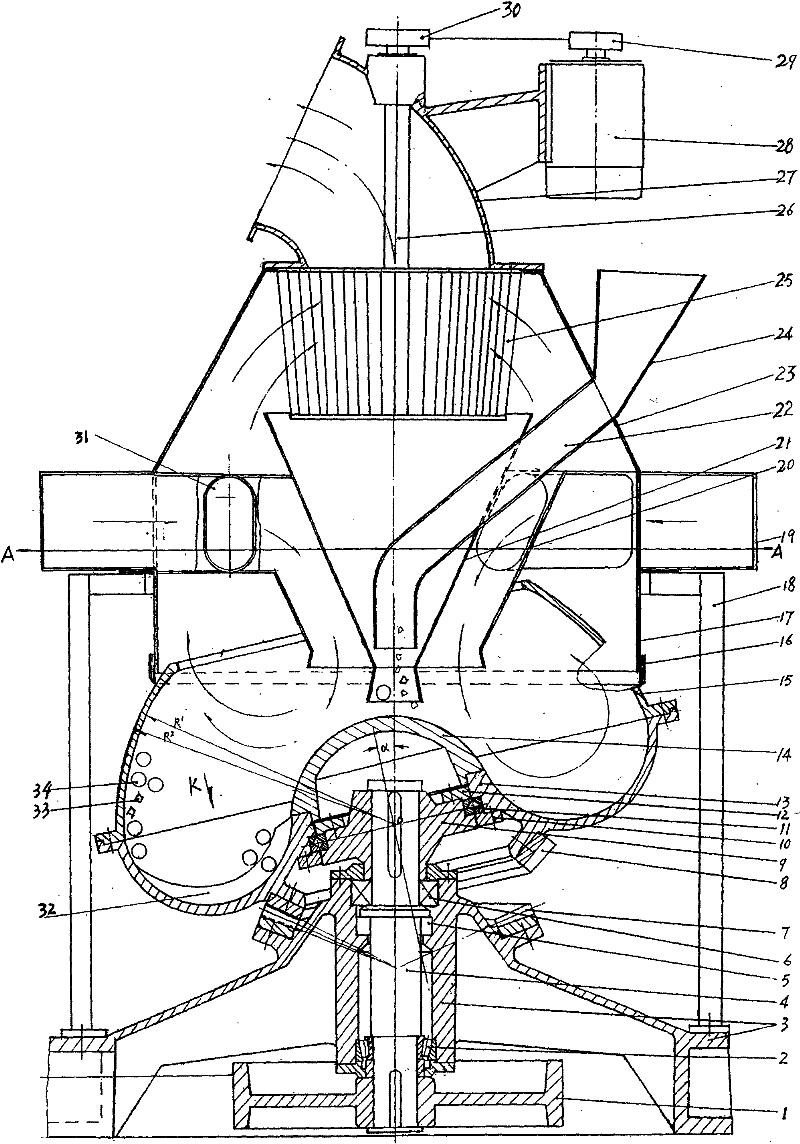

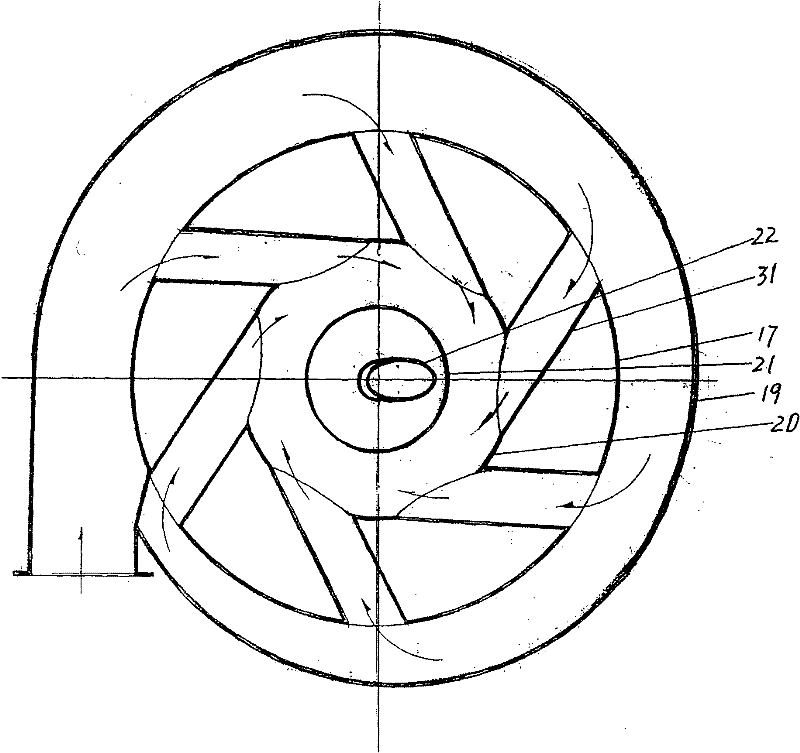

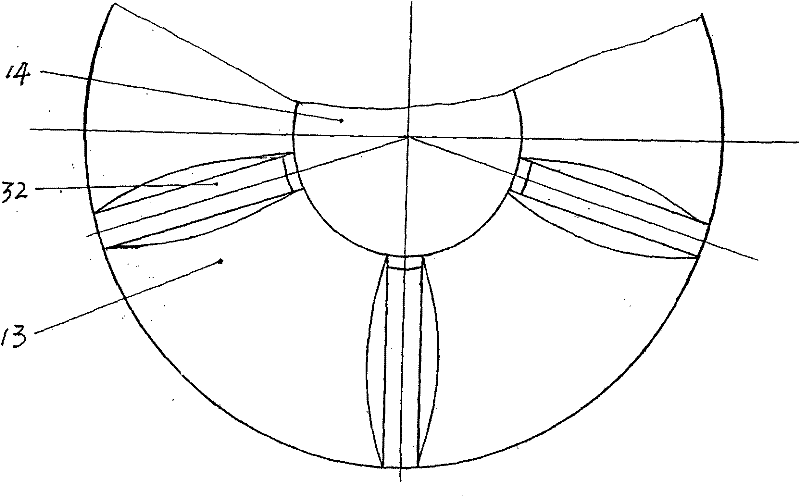

[0017] Such as figure 1 -- image 3 As shown, the power input pulley of a high-strength nutating centrifugal ball mill of the present invention 1. The vertically arranged main shaft 4. The lower bearing 2. The push bearing 5. The upper bearing 6 is installed on the base 3. The main shaft 4. The upper key is connected to the slanted hole bushing 9. The crossed roller bearing 11 on the slanted hole bushing is respectively connected by the lower pressure ring 10, the upper pressure ring 12 and the lower grinding chamber 13. The upper center surface of the lower grinding chamber 13 is equipped with a spherical convex Table 14. The radiating feeding bar 32 is arranged on the annular surface of the lower grinding chamber 13. The lower grinding chamber 13 is connected to the upper grinding chamber 15, and the upper limit ring 8. The lower limit ring 7. Forms the grinding mechanism of the high-strength nutating centrifugal ball mill . The winnowing mechanism of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com