Connecting structure of rear bumper and rear apron board of automobile

A connection structure and bumper technology, which is applied to the connection between sub-assemblies of the upper structure, upper structure, vehicle parts, etc., can solve the problems of water seepage and water accumulation in the trunk, and achieve high production efficiency, high efficiency, and preparation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

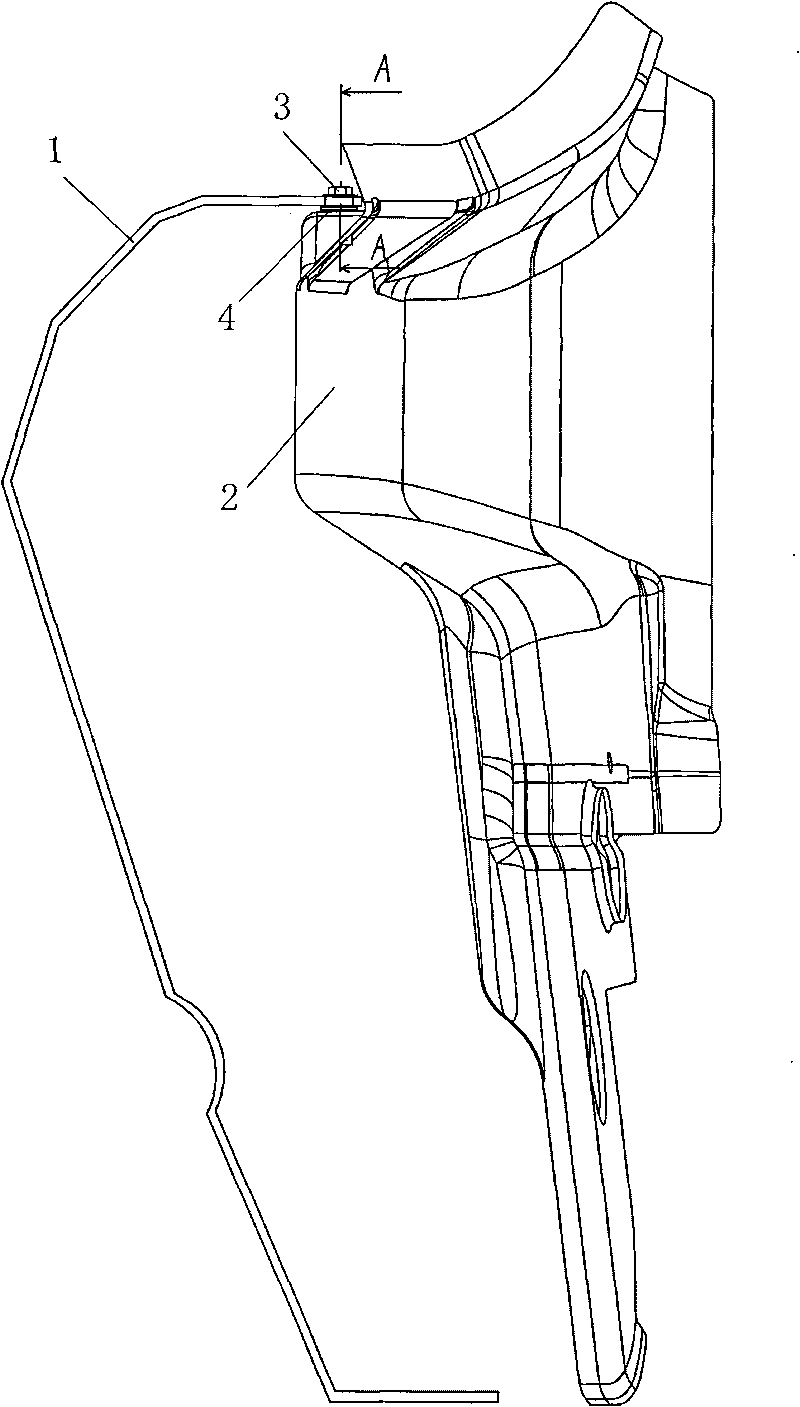

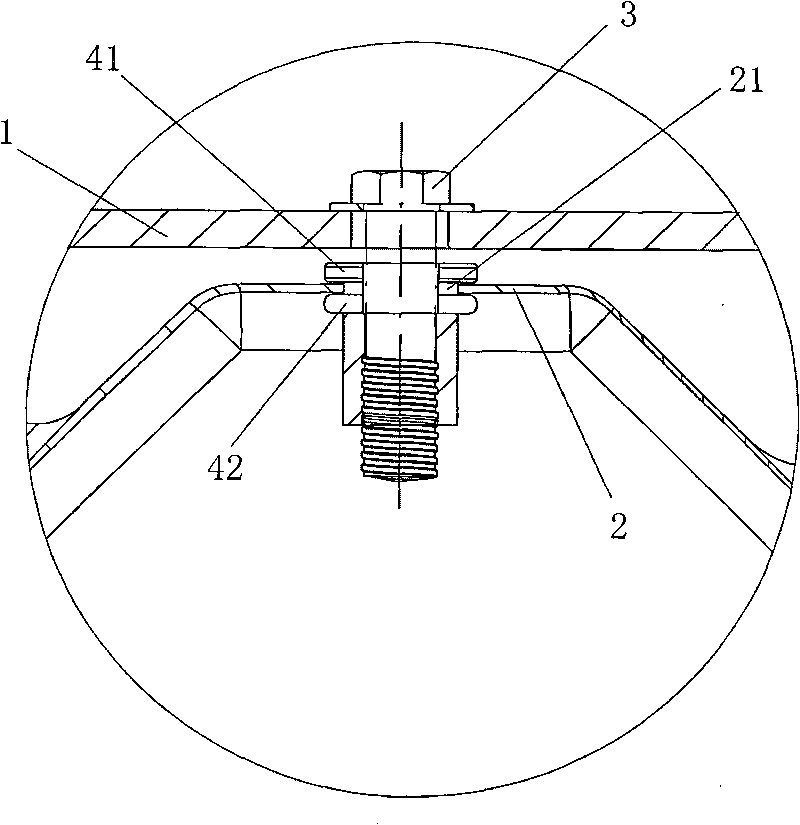

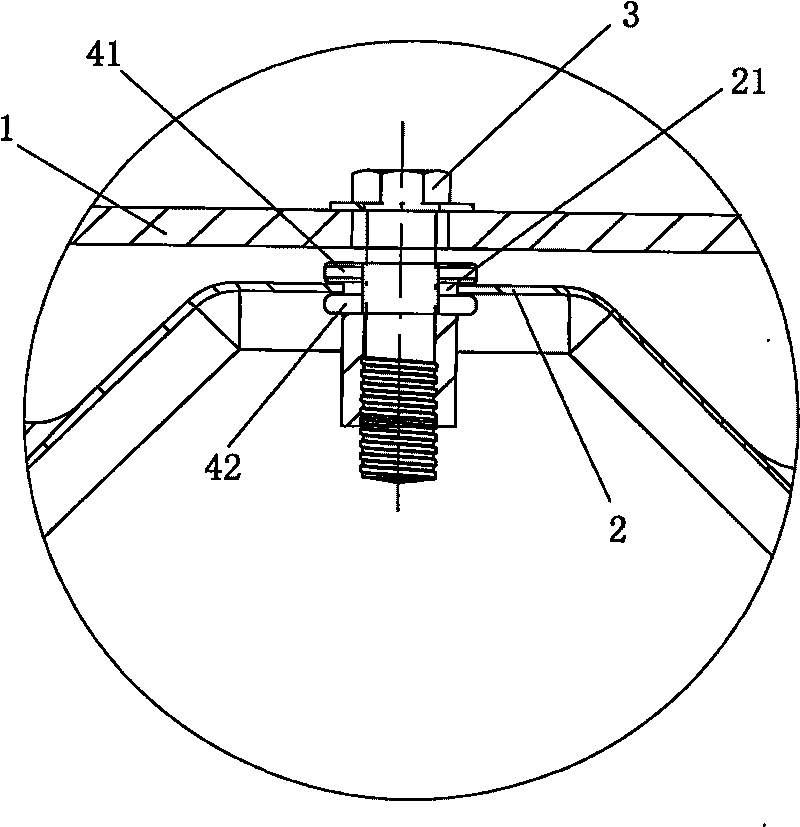

[0013] like figure 1 and figure 2 As shown, the present invention is a connection structure between a rear bumper and a rear apron of an automobile, mainly consisting of a rear bumper 1, a rear apron 2, bolts 3 and blind rivet nuts 4. Wherein, the rear apron 2 is provided with a bottom hole 21, and the blind rivet nut 4 is passed through the bottom hole 21 of the rear apron 2, and the first annular surface 41 of the blind rivet 4 head and the second ring surface 41 formed after installation are changed. The annular surface 42 clamps and closes the bottom hole 21, thereby fixing the blind rivet nut 4 on the rear skirt 2, and also seals the gap between the blind rivet 4 and the rear skirt 2, so that rainwater cannot pass through the gap between the two. into the luggage compartment. After the bolt 3 passes through the rear bumper 1 and the rivet nut 4, conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com