Gas film concrete construction formwork construction technology

A construction process and concrete technology, which is applied in the field preparation of formwork/formwork components and building components, and construction, etc., can solve the problems of difficulty in making concrete special-shaped curved formwork, inconvenient disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] The invention provides a construction technology of air film concrete construction formwork, specifically:

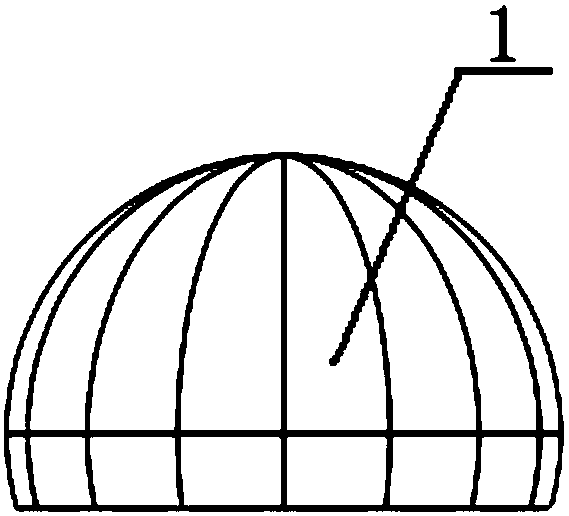

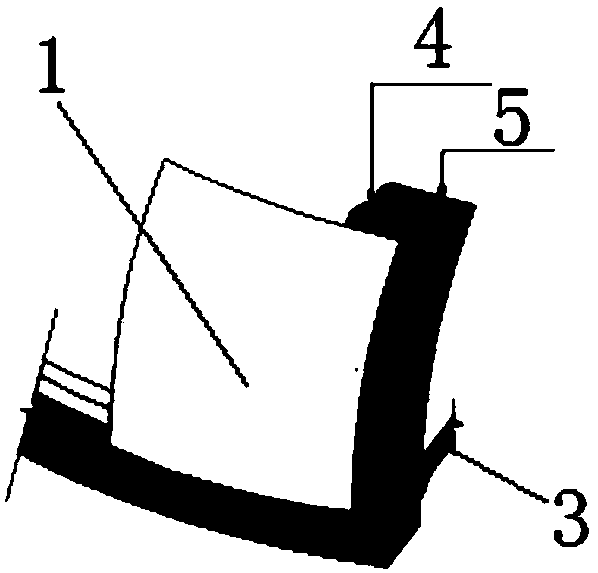

[0033] 1) Cut the membrane material 1 into sheets after calculating according to the shape of the building;

[0034] 2) After the membrane material 1 is cut, it is seamlessly spliced into the shape of the building by using high-speed friction; mainly using the high-frequency principle to apply the membrane material 1 between the upper and lower poles of a high-frequency electromagnetic field, so that the internal molecules are intensified and high-speed motion rubs against each other to generate heat and melt. Welding is achieved under mold pressure.

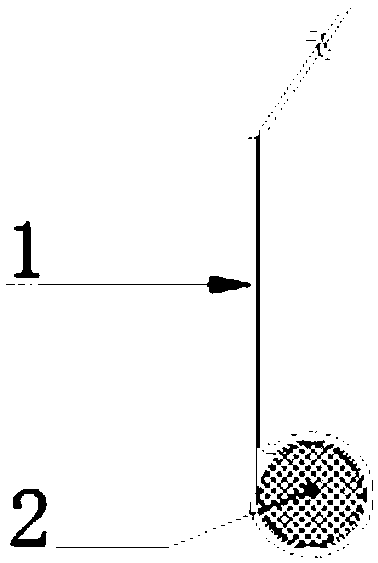

[0035] 3) Fix the formed membrane material 1 on the ring beam of the building foundation, and then use air supply equipment to press air into the inside of the membrane material 1, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com