Efficient nitrogen injection and fire extinguishing system for mining

An anti-fire and high-efficiency technology, applied in fire prevention, dust prevention, mining equipment, etc., to achieve the effect of reducing energy loss, simple operation, and reducing the effect of wall-attached condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

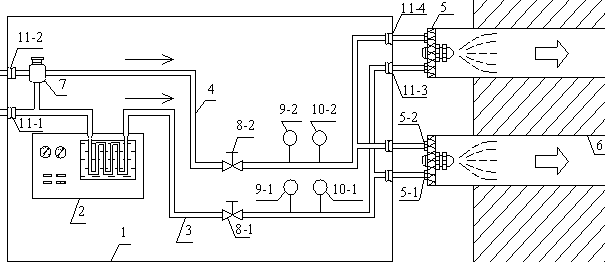

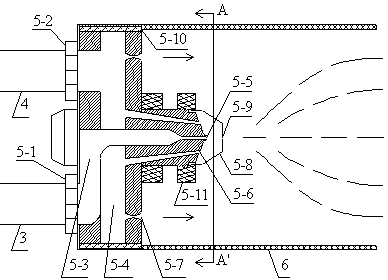

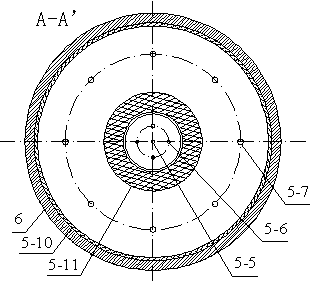

[0021] exist figure 1 Among them, the inlet of the refrigerator 2, the liquid inlet 11-1 are connected with the lower end of the three-way valve 7, the outlet of the refrigerator 2 is connected with the liquid inlet 5-1 of the atomizing nozzle 5 through the resisting liquid pipe 3, and the resisting liquid The pipe 3 is connected with a liquid pressure regulating valve 8-1, a liquid flow meter 9-1 and a liquid pressure gauge 10-1. The inlet of the three-way valve 7 is connected with the gas inlet 11-2, the outlet of the three-way valve 7 is connected with the gas inlet 5-2 of the atomizing nozzle through the nitrogen pipe 4, and the nitrogen pipe 4 is connected with a gas pressure regulating valve 8- 2. The gas flow meter 9-2 and the gas pressure gauge 10-2; the atomizing nozzle 5 is connected to the rear end of the nitrogen injection pipe 6 .

[0022] The resisting liquid in the resisting liquid pipe 3 is MgCl with a mass concentration of 10-30%. 2 , CaCl 2 , Inhibitor aqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com