Method for preparing nano composite material by supercritical fluid electroforming

A nano-composite material and supercritical fluid technology, applied in electroforming, electrolytic coating, electrolytic process, etc., can solve the problems of difficult control of electroforming layer uniformity and easy agglomeration of nanoparticles. smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

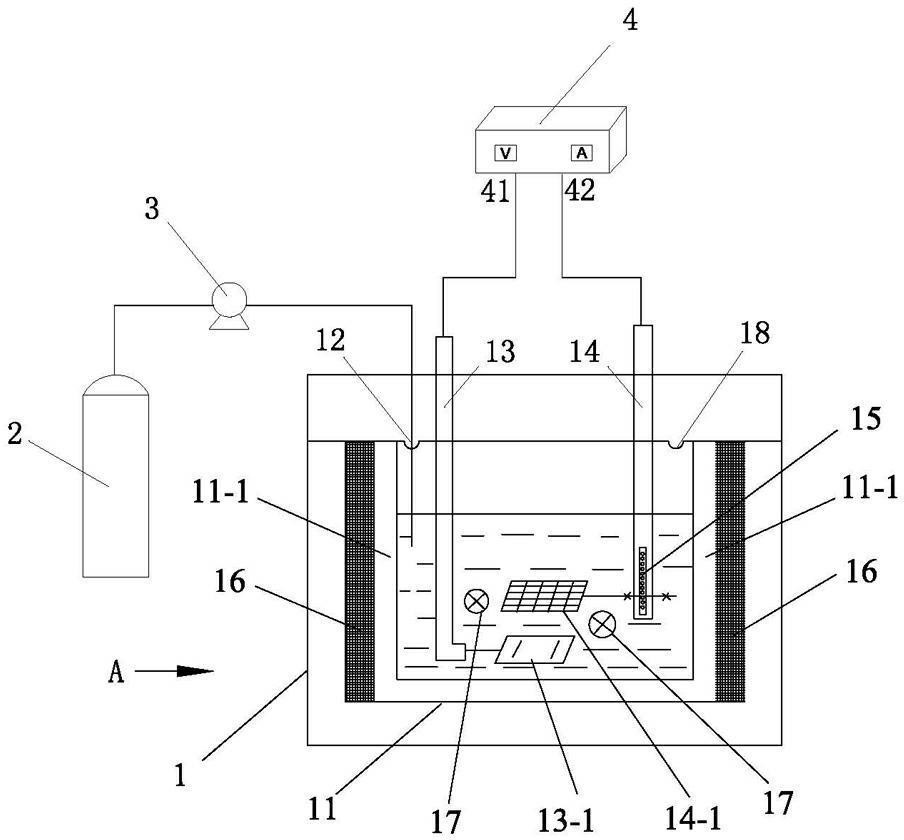

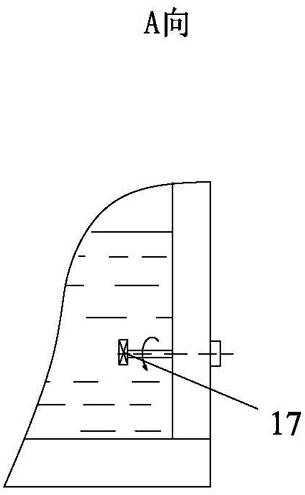

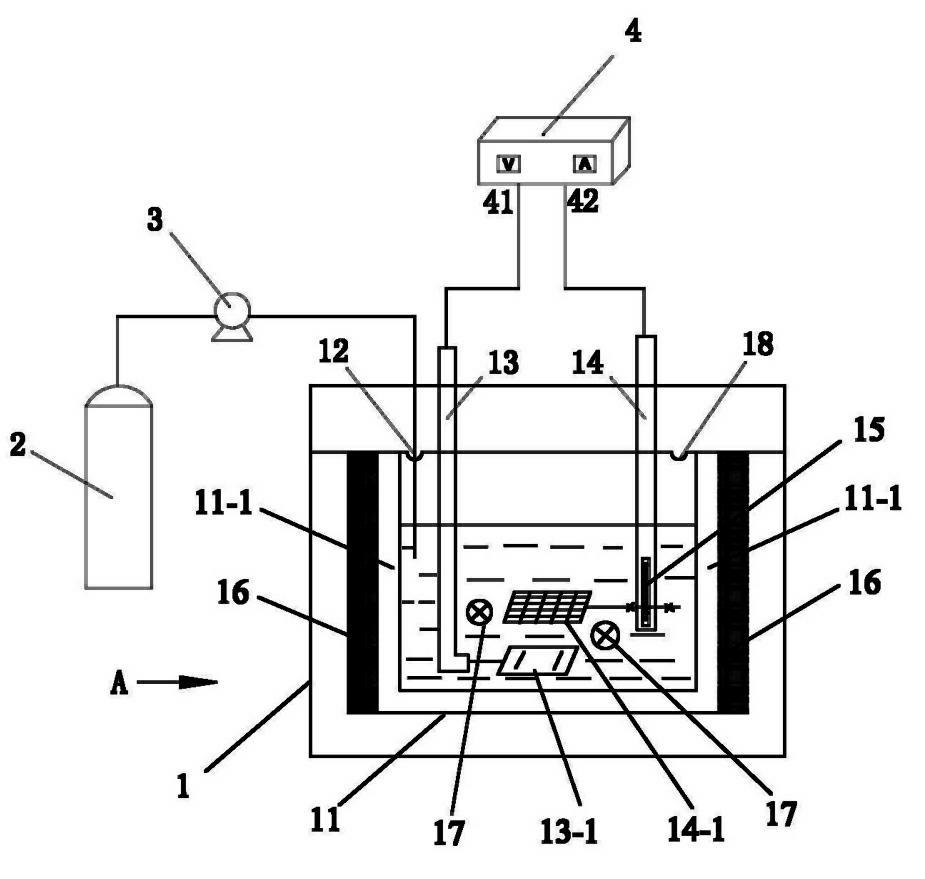

[0021] See figure 1 , The device used in the method of this embodiment includes an electroforming device 1 , a carbon dioxide gas cylinder 2 , a high-pressure pump 3 and a DC power supply 4 .

[0022] The electroforming device 1 has a reactor 11 , a cathode 13 , an anode 14 , an adjustment plate 15 , a heating coil 16 and a mechanical stirrer 17 . The reactor 11 is a closed pressure vessel, including a reactor main body 11-2 and a reactor lining 11-1. The reactor main body 11-2 is made of stainless steel or high-strength structural steel, and the reactor lining 11-1 is made of corrosion-resistant tetrafluoroethylene material. An air inlet 12 and a liquid outlet 18 are provided above the reactor main body 11 - 2 . The cathode 13 includes a cathode body 13-2 and a cathode template 13-1, and the anode 14 includes an anode body 14-2 and an anode template 14-1. The main body of the anode template 14-1 is a mesh metal plate, and the material of the mesh metal plate is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com