Method for regenerating (RE/HZSM-5) catalysts for resolving methanethiol gas

A catalyst, methyl mercaptan technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as waste liquid generation, water source pollution, environmental secondary pollution, etc., achieve good repeatability, eliminate Pollution, cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This implementation takes the deactivated 5wt%La / HZSM-5 catalyst as the treatment object, and the specific steps are as follows:

[0029] (1) Preparation of 5wt%La / HZSM-5 catalyst: put 5 grams of commercially available HZSM-5 molecular sieve with a silicon-aluminum ratio (Si / Al) of 25 into a muffle furnace, and bake it at 550°C for 5 hours, and set aside; Use the equal volume impregnation method to load the active component lanthanum (La) element; pre-weigh 1 gram of HZSM-5 and drop deionized water on the watch glass to determine the ability of the carrier to absorb the solution, and determine the water required to completely impregnate the carrier Dissolve 0.8204 grams of analytically pure lanthanum nitrate hexahydrate in 5.2 grams of deionized water, stir, and after completely dissolving, add 5 grams of pretreated HZSM-5 to this lanthanum nitrate solution, stir evenly, and Immerse for 12 hours to make it fully absorbed, then dry it at 80°C for 5 hours, move it into a ...

Embodiment 2

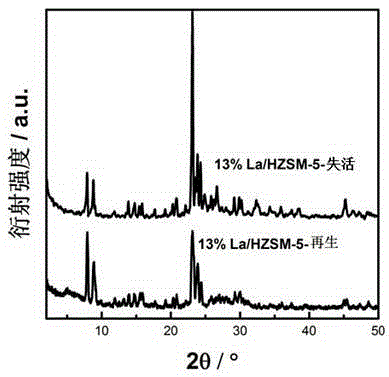

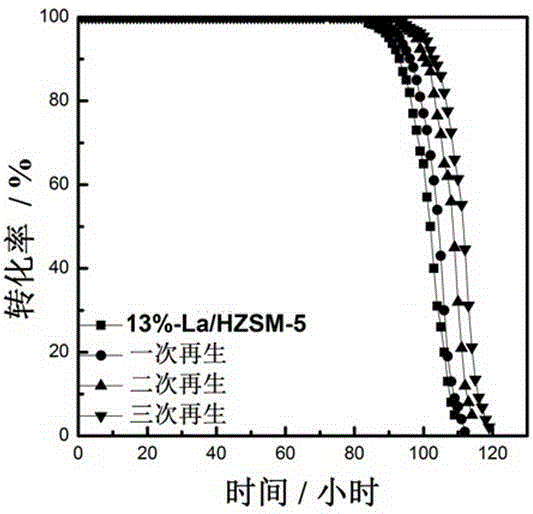

[0033] This implementation takes the deactivated 13wt%La / HZSM-5 catalyst as the treatment object, and the specific steps are as follows:

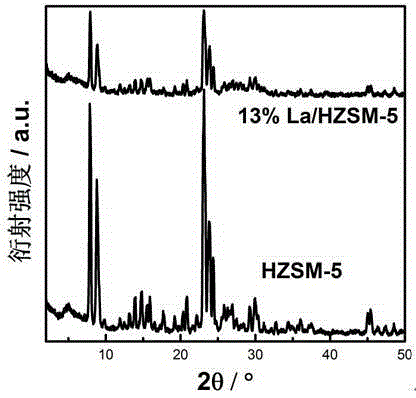

[0034](1) Preparation of 13wt% La / HZSM-5 catalyst: Put 5 grams of commercially available HZSM-5 molecular sieve with a silicon-to-aluminum ratio (Si / Al) of 25 into a muffle furnace, and bake it at 560°C for 4.5 hours, and set aside. The equal volume impregnation method is used to load the active component lanthanum (La) element. Weigh 1 gram of HZSM-5 in advance and add deionized water dropwise on the watch glass to determine the ability of the carrier to absorb the solution. It is determined that 1.04 grams of water is needed to completely impregnate the carrier. Dissolve 2.6331 grams of analytically pure lanthanum nitrate hexahydrate in 5.2 Add 5 grams of deionized water, stir, and after it is completely dissolved, add 5 grams of pretreated HZSM-5 to the cerium salt solution, stir evenly, soak at room temperature for 13 hours to make it f...

Embodiment 3

[0040] This implementation takes the deactivated 5wt%Ce / HZSM-5 catalyst as the treatment object, and the specific steps are as follows:

[0041] (1) Preparation of 5wt% Ce / HZSM-5 catalyst: Put 5 grams of commercially available HZSM-5 molecular sieve with a silicon-to-aluminum ratio (Si / Al) of 25 into a muffle furnace and calcinate at 540°C for 5.2 hours, and set aside. The equal volume impregnation method is used to load the active component cerium (Ce) element. Weigh 1 gram of HZSM-5 in advance and add deionized water dropwise on the watch glass to determine the ability of the carrier to absorb the solution. It is determined that the water needed to completely impregnate the carrier is 1.04 grams. Dissolve 0.8155 grams of analytically pure cerium nitrate hexahydrate in 5.2 Add 5 g of pretreated HZSM-5 to the cerium salt solution, stir evenly, and soak it at room temperature for 12.5 hours to fully absorb it, and then dry it at 90°C for 4 hours Then move it into a muffle furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com