Purification technique for methyl stannum mercaptide industrial sewage

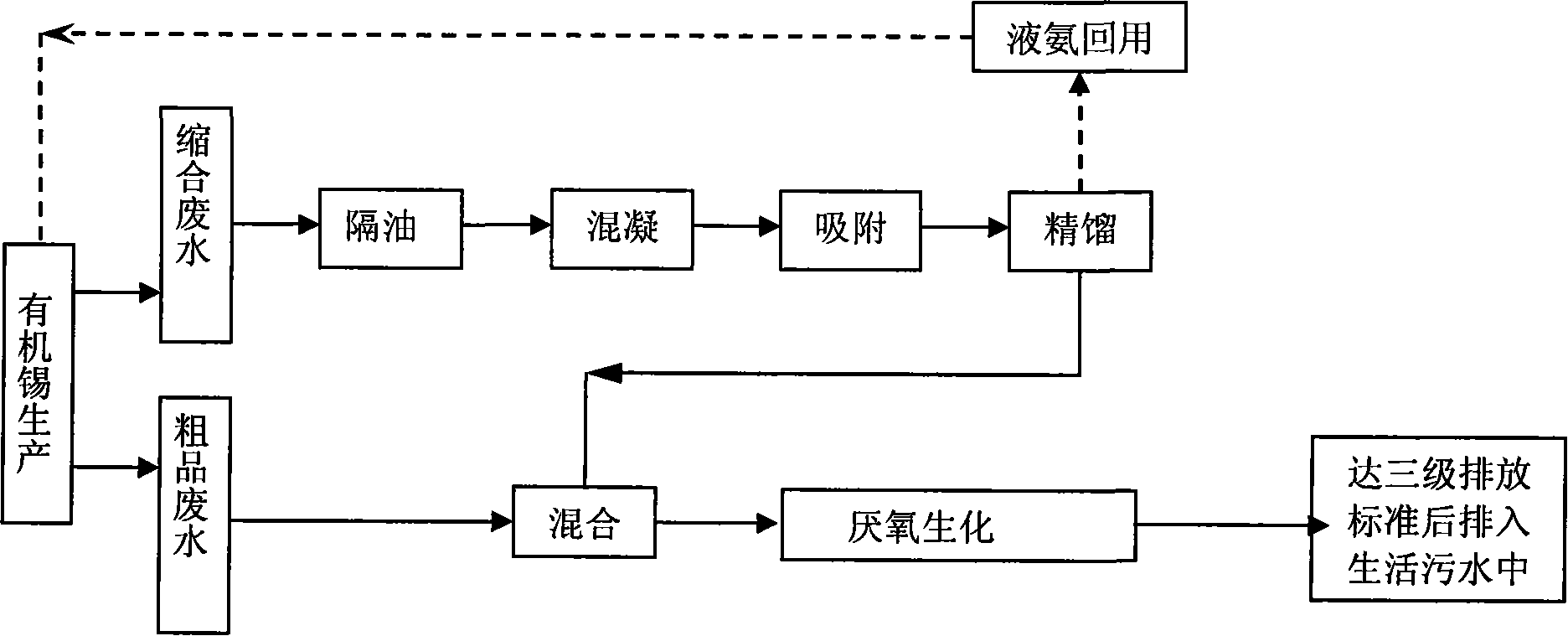

A technology of tin methyl mercaptide and industrial wastewater, which is applied in anaerobic digestion treatment, natural water treatment, chemical instruments and methods, etc., can solve problems such as immature industrial wastewater purification and treatment methods, achieve easy management and save operating costs , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A methyl mercaptide tin industrial wastewater, condensation wastewater water volume 10m 3 / d, water quality COD is 20000mg / L, NH 4 + -N is 40000mg / L, organotin content is 3000mg / L, Cl - The content of mercaptan is 8000mg / L, the content of mercaptan is 2000mg / L, the oil is separated by inclined plate, 5000mg / L ferric chloride is added, stirred and coagulated, filtered, and 80kg / m 3 Activated carbon adsorbent (specific surface is 600m 2 / g, the density is 470kg / m 3 ), after full adsorption, ammonia is separated by rectification, and the water volume is 70m 3 / d, water quality COD is 1000mg / L, NH 4 + -N is 30mg / L, Cl - The crude wastewater with a content of 300mg / L was mixed, and after 15 days of anaerobic biochemical treatment, the COD of the effluent was 430mg / L, and the NH 4 + -N is 50mg / L, total tin is 0.8mg / L, meets the third-level discharge requirements of the "Integrated Wastewater Discharge Standard", and is treated together with domestic sewage.

Embodiment 2

[0026] A methyl mercaptide tin industrial wastewater, condensation wastewater water volume 15m 3 / d, water quality COD is 200000mg / L, NH 4 + - Condensation waste water with N of 20000mg / L removes surface slick oil through an oil-water separator, adds 2000mg / L polyferric sulfate, stirs, coagulates, filters, and adds 100kg / m 3 Activated carbon adsorbent (specific surface is 1000m2 / g, the density is 490kg / m 3 ), after full adsorption, ammonia is separated by rectification, and the water volume is 80m 3 / d, water quality COD is 2000mg / L, NH 4 + -N is 20mg / L, Cl - The crude wastewater with a content of 350mg / L was mixed, and after 10 days of anaerobic biochemical treatment, the effluent COD was 475mg / L, NH 4 + -N is 41mg / L, total tin is 0.7mg / L, meets the third-level discharge requirements of the "Integrated Wastewater Discharge Standard", and is treated together with domestic sewage.

Embodiment 3

[0028] The treated condensation wastewater and crude product wastewater are the same as in Example 1.

[0029] Condensation waste water is removed by oil-water separator to remove surface slick oil, add 500mg / L polyferric chloride and stir for 2 hours, add polyacrylamide 20mg / L, continue stirring for 10 minutes, let stand for 3 hours, filter, add 167kg / m 3 Sawdust adsorbent, fully adsorbed, and then separated ammonia by rectification, mixed with crude waste water, after 6 days of anaerobic biochemical treatment, the effluent COD is 400mg / L, NH 4 + -N is 46mg / L, and total tin is 0.7mg / L, which meets the third-level discharge requirements of the "Integrated Wastewater Discharge Standard" and is treated together with domestic sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com