Green methyl tin mercaptide compound

A technology of tin methyl mercaptide and complexes, which is applied in the directions of tin organic compounds, compounds of elements of Group 4/14 of the periodic table, chemical instruments and methods, etc. Improvement, mold release, poor lubricity, etc., to increase the effect of yellowing resistance, excellent dispersion and stability, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

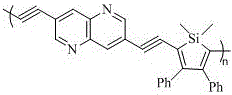

Image

Examples

Embodiment 1

[0040] Green tin methyl mercaptide compound, which is prepared by the following steps:

[0041] (1) Tinization: Put metal tin and catalyst into a pressure-resistant and acid-resistant reaction kettle, then pass in methyl chloride and heat and mix evenly at 150°C, carry out halogenation reaction for 0.2h, then add redistribution agent tin tetrachloride and Raise the temperature to 235°C, pressurize to 0.5MPa to carry out the tinning reaction for 1 hour, then distill and accept the fraction with a gas temperature within 150°C, and then absorb it with pure water to obtain an aqueous solution of methyl tin chloride;

[0042] The methyl alkene chloride comprises dimethyl tin dichloride and monomethyl tin trichloride; the first catalyst is a mixture of tetrabutyl ammonium bromide and dimethyl sulfide according to the molar mass ratio of 1:2; the second The weight of a catalyst accounts for 1% of the weight of metallic tin.

[0043] (2) Synthesis: add the obtained methyl tin chlorid...

Embodiment 2

[0054] Green tin methyl mercaptide compound, which is prepared by the following steps:

[0055] (1) Tinization: Put metal tin and catalyst into a pressure-resistant and acid-resistant reactor, then pass in methyl chloride, heat and mix evenly at 170°C, carry out halogenation reaction for 0.4h, then add redistribution agent tin tetrachloride and Raise the temperature to 235-245°C, pressurize to 0.5-0.8MPa to carry out the tinning reaction for 2 hours, then distill and accept the fraction whose gas temperature is within 230°C, and then absorb it with pure water to obtain an aqueous solution of methyl tin chloride;

[0056] Methyl olefin chloride comprises dimethyl tin dichloride and monomethyl tin trichloride; The first catalyst is the mixture of tetrabutyl ammonium chloride and dimethyl sulfide according to the molar mass ratio of 1: 3; The weight of a catalyst accounts for 3% of the metal tin weight.

[0057] (2) Synthesis: add the obtained methyl tin chloride aqueous solutio...

Embodiment 3

[0068] Green tin methyl mercaptide compound, which is prepared by the following steps:

[0069] (1) Tinization: Put metal tin and catalyst into a pressure-resistant and acid-resistant reaction kettle, then pass in methyl chloride and heat and mix evenly at 160°C, carry out halogenation reaction for 0.3h, then add redistribution agent tin tetrachloride and Raise the temperature to 240°C, pressurize to 0.6MPa to carry out the tinning reaction for 1.5 hours, then distill and accept the fraction whose gas temperature is within 200°C, and then absorb it with pure water to obtain an aqueous solution of methyl tin chloride;

[0070] Methyl olefin chlorides include dimethyl tin dichloride and monomethyl tin trichloride; the first catalyst is a mixture of trioctyl methyl ammonium chloride and dimethyl sulfide in a molar mass ratio of 1:2.5 ; The weight of the first catalyst accounts for 2% of the metal tin weight.

[0071] (2) Synthesis: add the obtained methyl tin chloride aqueous so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com