Insulating material for nuclear power plant and production technology thereof

An insulating material and nuclear power plant technology, applied in the field of insulating material preparation, can solve the problems of insulating materials such as corrosion resistance, poor pressure resistance, and short service life, and achieve excellent acid and alkali resistance, long service life, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

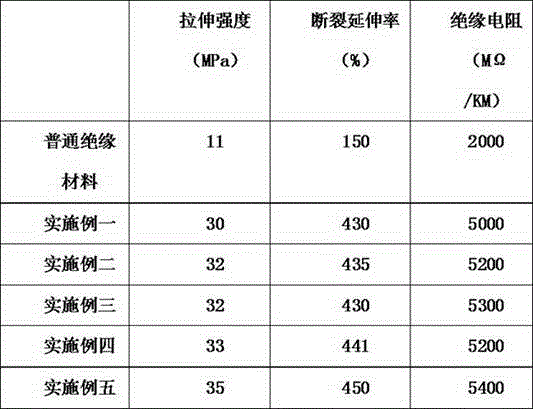

Examples

Embodiment 1

[0017] The proportion of ingredients used is: 30 parts of rubber matrix, 15 parts of flame retardant, 8 parts of silane coupling agent, 10 parts of chlorinated polyethylene, 1 part of ultraviolet absorber, 4 parts of tin mercaptide, toughening modification 5 parts of agent, 15 parts of polyolefin compound, 15 parts of polystyrene resin, 8 parts of nano-scale silicon dioxide, 8 parts of cross-linked fluororesin, 10 parts of composite antioxidant and 10 parts of reinforcing fiber.

[0018] In this embodiment, the rubber matrix is composed of 30% ethylene propylene rubber, 50% nitrile rubber and 20% methyl trifluoropropyl silicone rubber.

[0019] In this embodiment, the reinforcing fiber is composed of 30% steel fiber, 30% glass fiber and 40% plant fiber.

[0020] The production technique of the present embodiment comprises the following steps:

[0021] A. Add the rubber matrix, flame retardant, silane coupling agent, chlorinated polyethylene, and ultraviolet absorber into th...

Embodiment 2

[0026] The proportion of ingredients used is: 35 parts of rubber matrix, 18 parts of flame retardant, 9 parts of silane coupling agent, 12 parts of chlorinated polyethylene, 2 parts of ultraviolet absorber, 5 parts of tin mercaptide, toughening modification 7 parts of agent, 17 parts of polyolefin compound, 17 parts of polystyrene resin, 9 parts of nano-scale silicon dioxide, 9 parts of cross-linked fluororesin, 11 parts of composite antioxidant and 12 parts of reinforcing fiber.

[0027] In this embodiment, the rubber matrix is composed of 30% ethylene propylene rubber, 50% nitrile rubber and 20% methyl trifluoropropyl silicone rubber.

[0028] In this embodiment, the reinforcing fiber is composed of 30% steel fiber, 30% glass fiber and 40% plant fiber.

[0029] The production technique of the present embodiment comprises the following steps:

[0030] A. Add the rubber matrix, flame retardant, silane coupling agent, chlorinated polyethylene, and ultraviolet absorber into t...

Embodiment 3

[0035] The proportion of ingredients used is: 50 parts of rubber matrix, 30 parts of flame retardant, 12 parts of silane coupling agent, 20 parts of chlorinated polyethylene, 4 parts of ultraviolet absorber, 10 parts of tin methyl mercaptide, toughening modification 15 parts of agent, 25 parts of polyolefin compound, 30 parts of polystyrene resin, 15 parts of nano-scale silicon dioxide, 15 parts of cross-linked fluororesin, 15 parts of composite antioxidant and 30 parts of reinforcing fiber.

[0036] In this embodiment, the rubber matrix is composed of 30% ethylene propylene rubber, 50% nitrile rubber and 20% methyl trifluoropropyl silicone rubber.

[0037] In this embodiment, the reinforcing fiber is composed of 30% steel fiber, 30% glass fiber and 40% plant fiber.

[0038] The production technique of the present embodiment comprises the following steps:

[0039] A. Add the rubber matrix, flame retardant, silane coupling agent, chlorinated polyethylene, and ultraviolet abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com