Tubular fixed bed reactor for methanethiol

A fixed-bed reactor and tube-and-tube technology, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult maintenance and reaction gas cannot be cooled in time, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

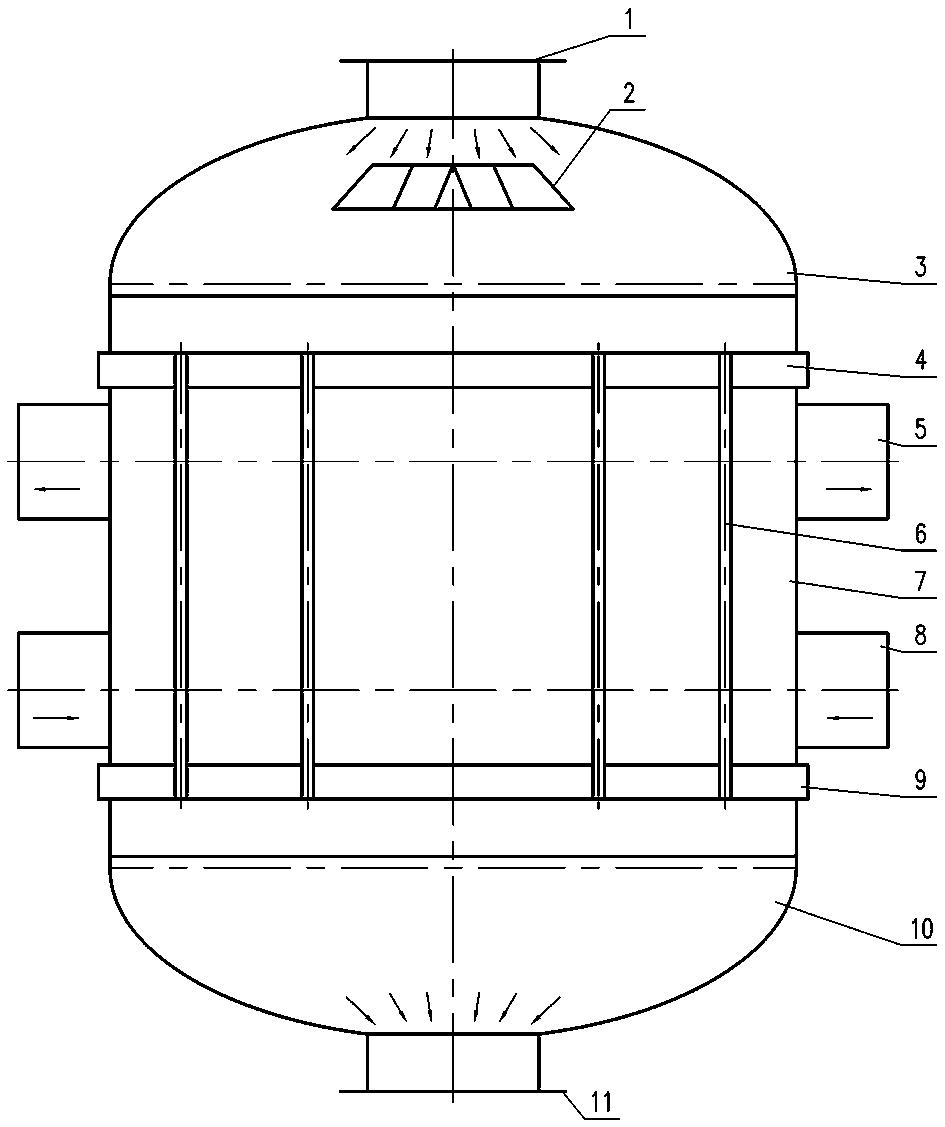

[0031] The reactant gas enters the upper pipe box 3 from the reactant gas inlet 1 through the gas distributor 2, and the reactant gas enters each reaction tube 6 evenly, reacts and releases heat under the action of the catalyst, and the catalyst is supported by the catalyst support spring 12 In the reaction tube 6 , the reactant gas after the reaction leaves the reaction tube 6 and is discharged from the reactant gas outlet 11 at the lower part of the lower tube box 10 .

Embodiment 2

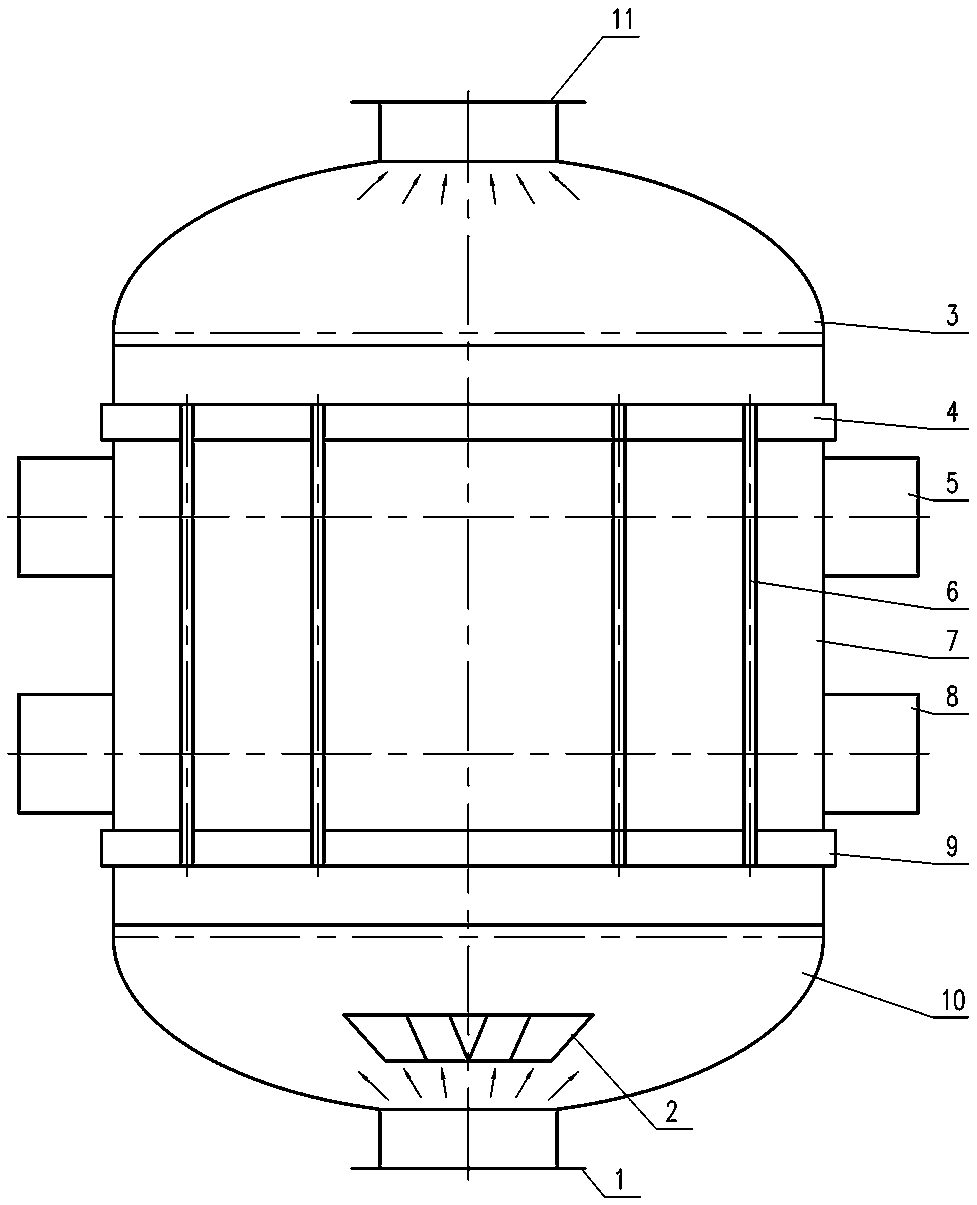

[0033] The reactant gas enters the lower tube box 10 from the reactant gas inlet 1 through the gas distributor 2, and the reactant gas enters each reaction tube 6 evenly, reacts and releases heat under the action of the catalyst, and the catalyst is supported by the catalyst support spring 12 In the reaction tube 6 , the reactant gas after the reaction leaves the reaction tube 6 and is discharged from the reactant gas outlet 11 on the upper part of the upper tube box 3 .

[0034] During operation, the shell-side heat-conducting medium circulates from bottom to top, flows into the shell-side cylinder 7 from the nozzle of the lower ring chamber 8, flows countercurrently upwards, exchanges heat with the reaction tube 6, and finally flows out from the nozzle of the upper ring chamber 5 and moves out heat of reaction.

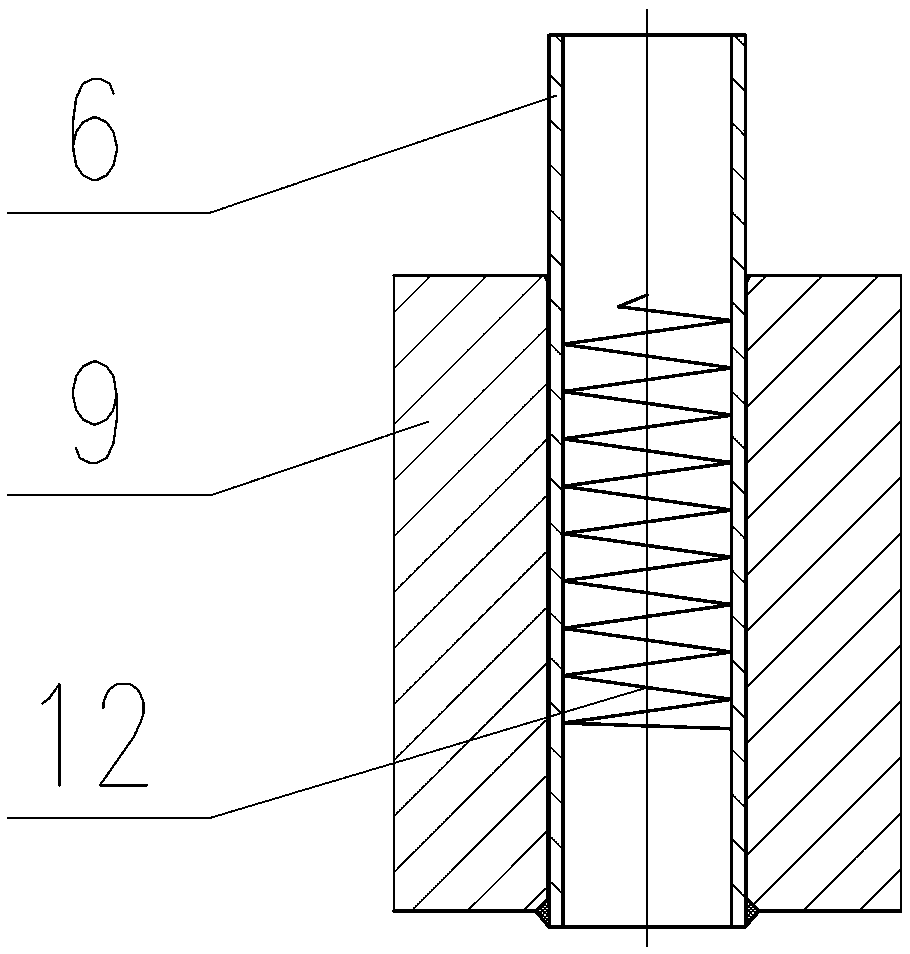

[0035] The catalyst supporting spring 12 is a composite spring, which is screwed into the reaction tube 6 and clamped tightly with the tube wall to ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com