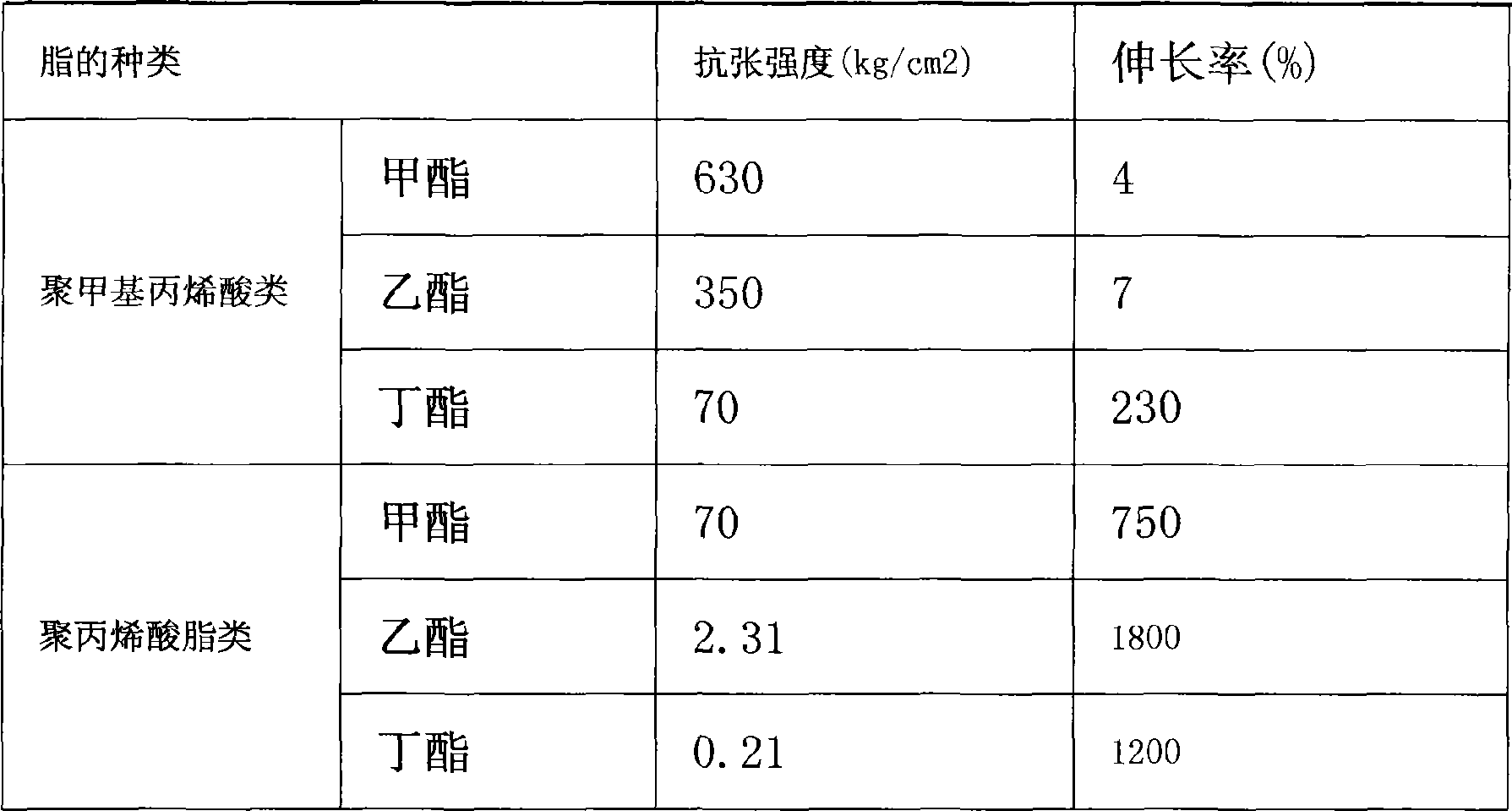

Preparation of medicinal poly(methyl acrylamide) with low film forming temperature and medium permeability

A technology of polymethacrylate and film-forming temperature, applied to the application of water-soluble drug sustained-release coating, in the field of osmotic polymethacrylate, can solve the problems of limited promotion, complicated formulation, etc. The effect of easy industrialization, reduced equipment investment, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

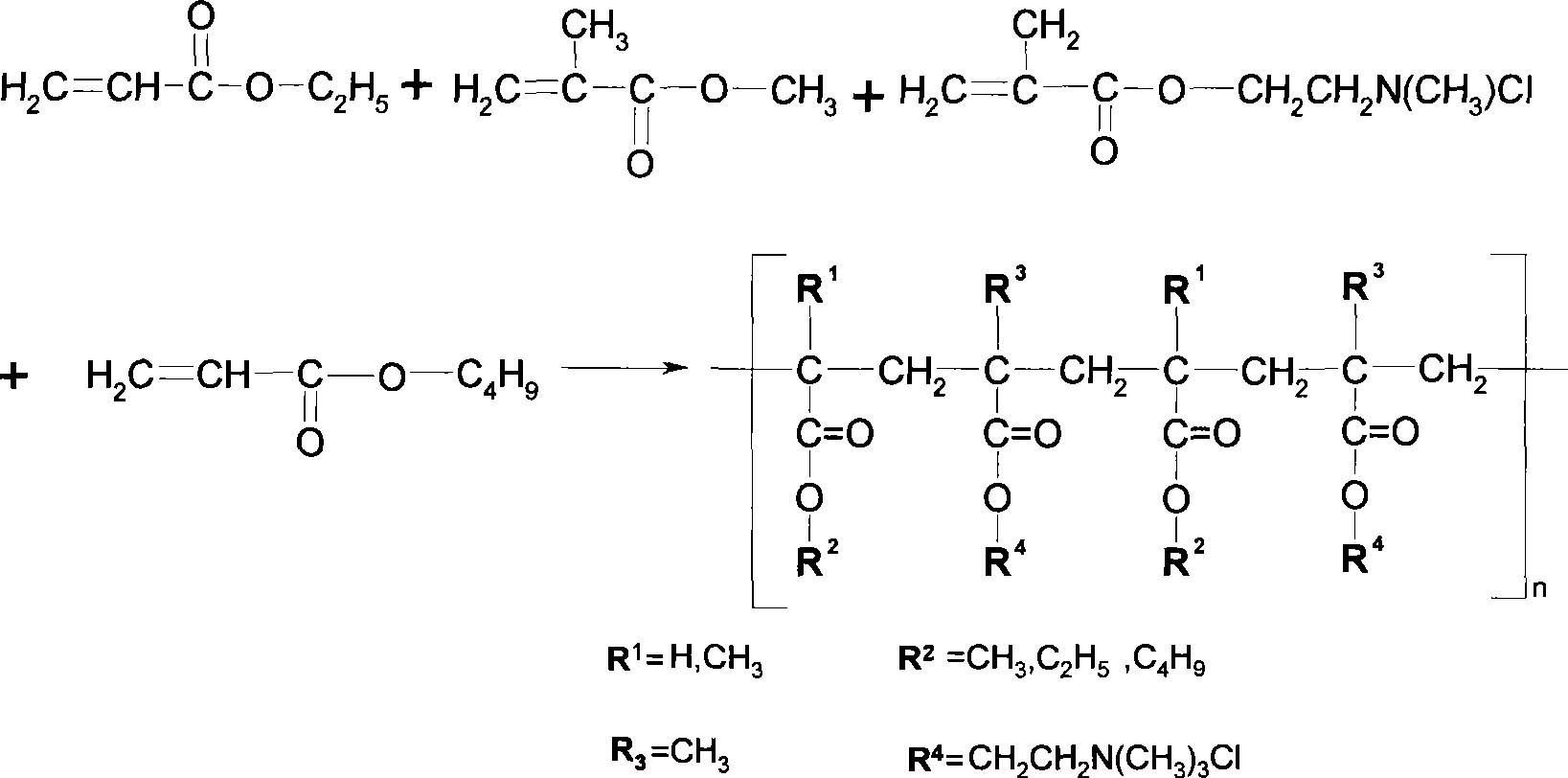

Method used

Image

Examples

no. 1 approach

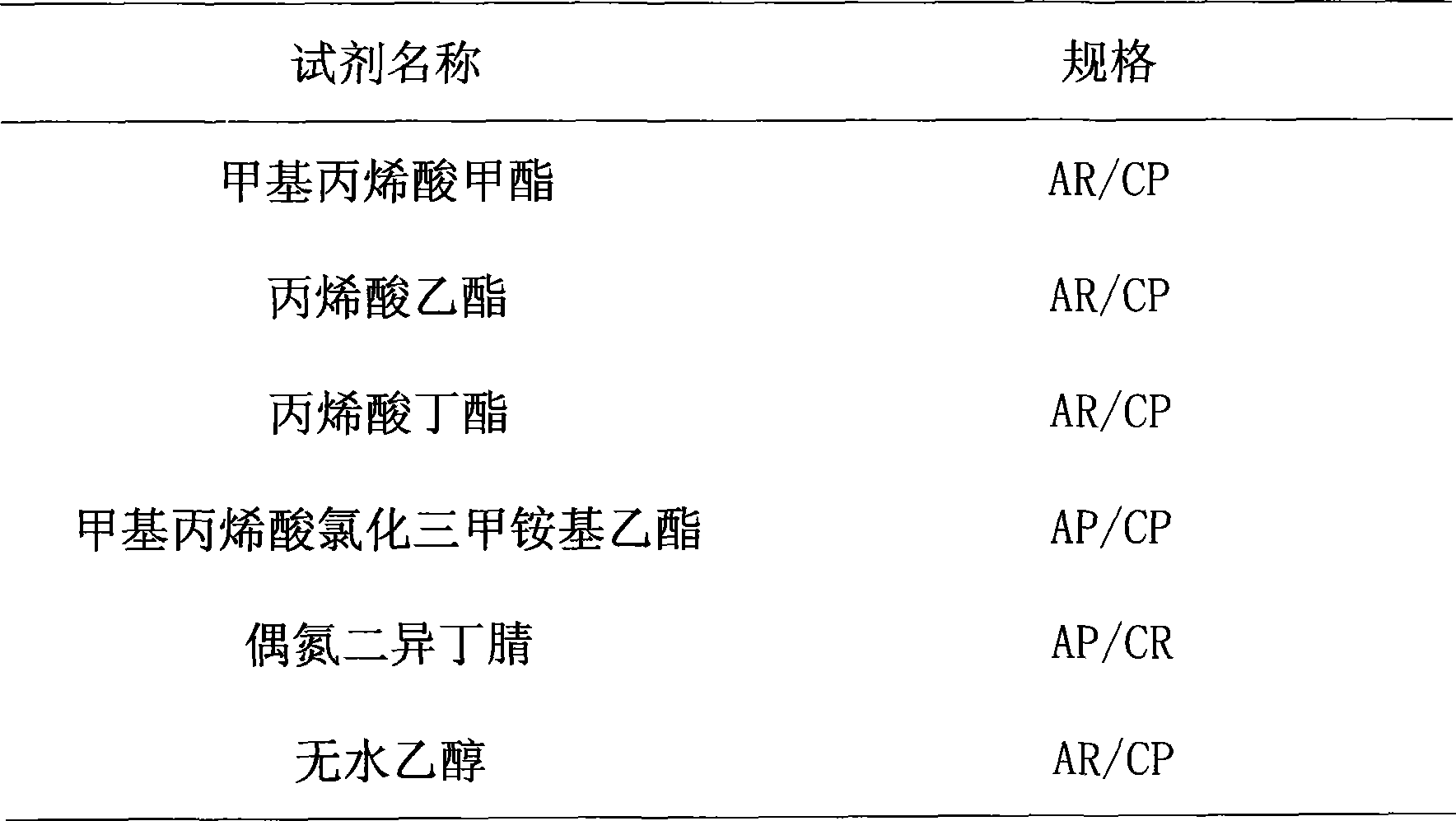

[0040] Take 0.33ml of ethyl acrylate, 4.36ml of butyl acrylate, 3.4ml of methyl methacrylate, 0.96g of trimethylammonium ethyl methacrylate chloride, first use 1ml of anhydrous Dissolve ethanol, and then add it to a four-neck flask equipped with an electric stirrer, reflux condenser, and thermometer, add 0.02g AIBN, turn on the electric stirrer, and control the speed at 100r~200r / min, without pre-reaction, directly dissolve the polymer The temperature was continuously raised from 30 to 110°C for 8 hours, and the temperature was continuously raised for 5 hours before 65°C to ensure that the monomer reaction was complete, and the reaction was completed. The product was a light yellow translucent solid. The Tg of the obtained polymer was 28.3°C, the number average molecular weight was 45012, and the base value was 3.83 mg / g.

no. 2 approach

[0042] Take 16.6ml of ethyl acrylate, 21.8ml of butyl acrylate, 17ml of methyl methacrylate, 4.82g of trimethylammonium ethyl methacrylate chloride, first use 5ml of absolute ethanol Dissolve, then add to the four-necked bottle equipped with electric stirrer, reflux condenser, and thermometer, add 0.1gAIBN, turn on the electric stirrer, control the speed at 100r~200r / min, do not carry out pre-reaction, directly polymer from 30-110°C was continuously heated for 8 hours, and the temperature was continuously raised for 5h before 65°C to ensure that the monomer reaction was complete, and the reaction was completed. The product was a light yellow translucent solid. The Tg of the obtained polymer was 28.3°C, the number average molecular weight was 45012, and the base value was 19.15 mg / g.

no. 3 approach

[0044] Take 8.3ml of ethyl acrylate, 10.9ml of butyl acrylate, 34ml of methyl methacrylate, 5.43g of trimethylammonium ethyl methacrylate chloride, first use 10ml of absolute ethanol Dissolve, then add to a four-neck flask equipped with an electric stirrer, reflux condenser, and thermometer, add 0.15g AIBN, turn on the electric stirrer, control the speed at 100r~200r / min, slowly raise the temperature to 55°C, and pre-react for 0.5h , stop heating, cool to room temperature, and then continuously raise the temperature of the polymer from 30 to 110°C for 8 hours, and continue to raise the temperature for 3 hours before 65°C to ensure that the monomer reaction is complete, and the reaction is completed. The product is a light yellow translucent solid. The Tg of the obtained polymer was 29.4°C, the number average molecular weight was 40719, and the base value was 22.19 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com