Trimethylamine gas sensor and preparation method thereof

A gas sensor, trimethylamine technology, applied in the field of trimethylamine gas sensor and its preparation, can solve the problems of poor sensitivity, long response time, low resolution, etc., achieve low working temperature, short response and recovery time, anti- disruptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

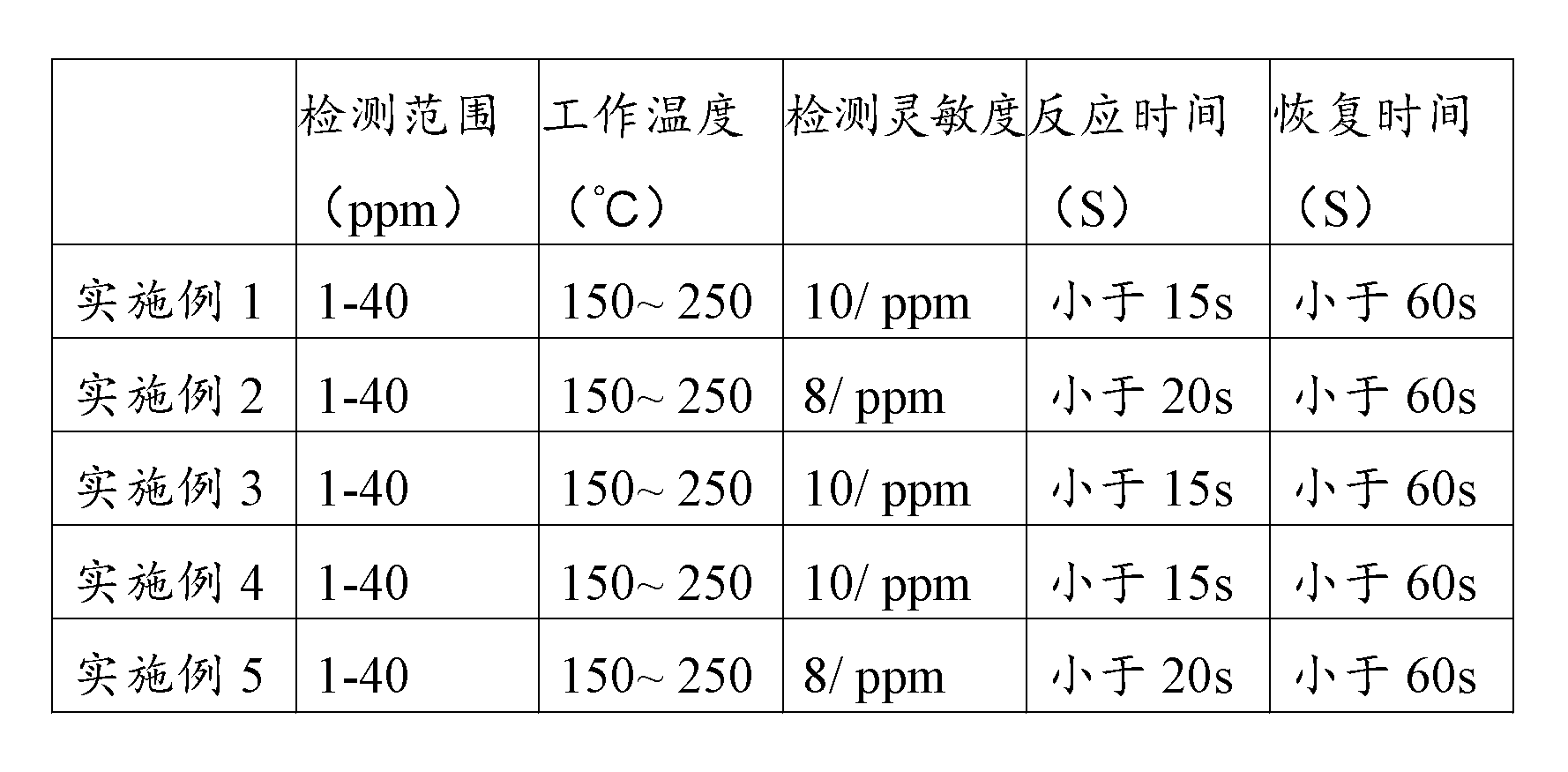

Examples

Embodiment 1

[0024] A kind of trimethylamine gas sensitive sensor, comprises gas sensitive electrode tube, and described gas sensitive electrode tube is made of Al 2 o 3 The ceramic tube is used as the carrier, with nano-SnO 2 It is a gas-sensitive material, and the gas-sensitive material contains SnO 2 2.5% Eu by molar mass 3+ .

[0025] The preparation steps are as follows:

[0026] 1) Nano SnO 2 Preparation: Weigh 3.5060g of SnCl 4 ·5H 2 O and 6.8458 g of sucrose were dissolved in double distilled water to prepare 70 mL of a mixed clear solution. Transfer the solution into a polytetrafluoroethylene-lined reaction kettle, cover it tightly, and raise the temperature to 180°C, react at a constant temperature for 12 hours, take it out, and let it cool naturally. Open the reaction kettle, take out the inner liner, pour out the resulting black reactant, and wash it several times with absolute ethanol and distilled water (using AgNO 3 There is no residual Cl- in the solution detection...

Embodiment 2

[0031] A kind of trimethylamine gas sensitive sensor, comprises gas sensitive electrode tube, and described gas sensitive electrode tube is made of Al 2 o 3 The ceramic tube is used as the carrier, with nano-SnO 2 It is a gas-sensitive material, and the gas-sensitive material contains SnO 2 2% La by molar mass 3+ .

[0032] The preparation steps are as follows:

[0033] 1) Preparation of gas-sensitive material: weigh 17.53g of SnCl 4 ·5H 2 O and 34.23 g of sucrose, SnCl 4 ·5H 2 The molar ratio of O to sucrose is 1?2, and 0.433g of La(NO 3 ) 3 make the final La 2 o 3 and SnO 2 The molar ratio of 2% was dissolved in 400 mL of twice distilled water under stirring conditions. Put the solution into a reaction kettle with a polytetrafluoroethylene liner, cover it tightly and raise the temperature to 150°C, react at a constant temperature for 24 hours, take it out, and let it cool naturally. Open the reaction kettle, take out the lining, pour out the resulting black rea...

Embodiment 3

[0037] A kind of trimethylamine gas sensitive sensor, comprises gas sensitive electrode tube, and described gas sensitive electrode tube is made of Al2 o 3 The ceramic tube is used as the carrier, with nano-SnO 2 It is a gas-sensitive material, and the gas-sensitive material contains SnO 2 3% Eu by molar mass 3+ .

[0038] The preparation steps are as follows:

[0039] 1) Nano SnO 2 Preparation: Weigh 35.060g of SnCl 4 ·5H 2 O and 68.458 g of sucrose were dissolved in double distilled water to prepare 1000 mL of a mixed clear solution. Put the solution into a reaction kettle with a polytetrafluoroethylene liner, cover it tightly and raise the temperature to 200°C, react at a constant temperature for 4 hours, take it out, and let it cool naturally. Open the reaction kettle, take out the lining, pour out the resulting black reactant, wash three times with distilled water and absolute ethanol respectively, dry the black product, heat it to 550°C in a muffle furnace, and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com