Doped cuprous oxide nano-material and preparation method and application thereof

A technology of cuprous oxide and nanomaterials, applied in the field of nanomaterials and photoelectric functional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Cuprous thiocyanate thin film can be prepared by reacting copper film with thiocyanate aqueous solution. [(1) Xu Wei, Xiao Xingxing, Xia Peng, A cuprous oxide nanowire porous film and its preparation method and application, invention patent application number: 2014100140030].

[0032] The cuprous thiocyanate film is immersed in the "zinc ion-thiocyanate" aqueous solution for adsorption, and then reacted with the alkali solution to prepare a zinc-doped cuprous oxide film:

[0033] Mix 5 ml of 0.5 mol / L sodium thiocyanate solution with 10 ml of 0.1 mol / L zinc sulfate aqueous solution, then immerse the cuprous thiocyanate film on the flexible plastic substrate, soak for 20 minutes, take it out, remove Excess solution; then immerse the film sample in excess sodium hydroxide aqueous solution, soak for 1 hour, take it out, wash, and dry to prepare a zinc-doped cuprous oxide film.

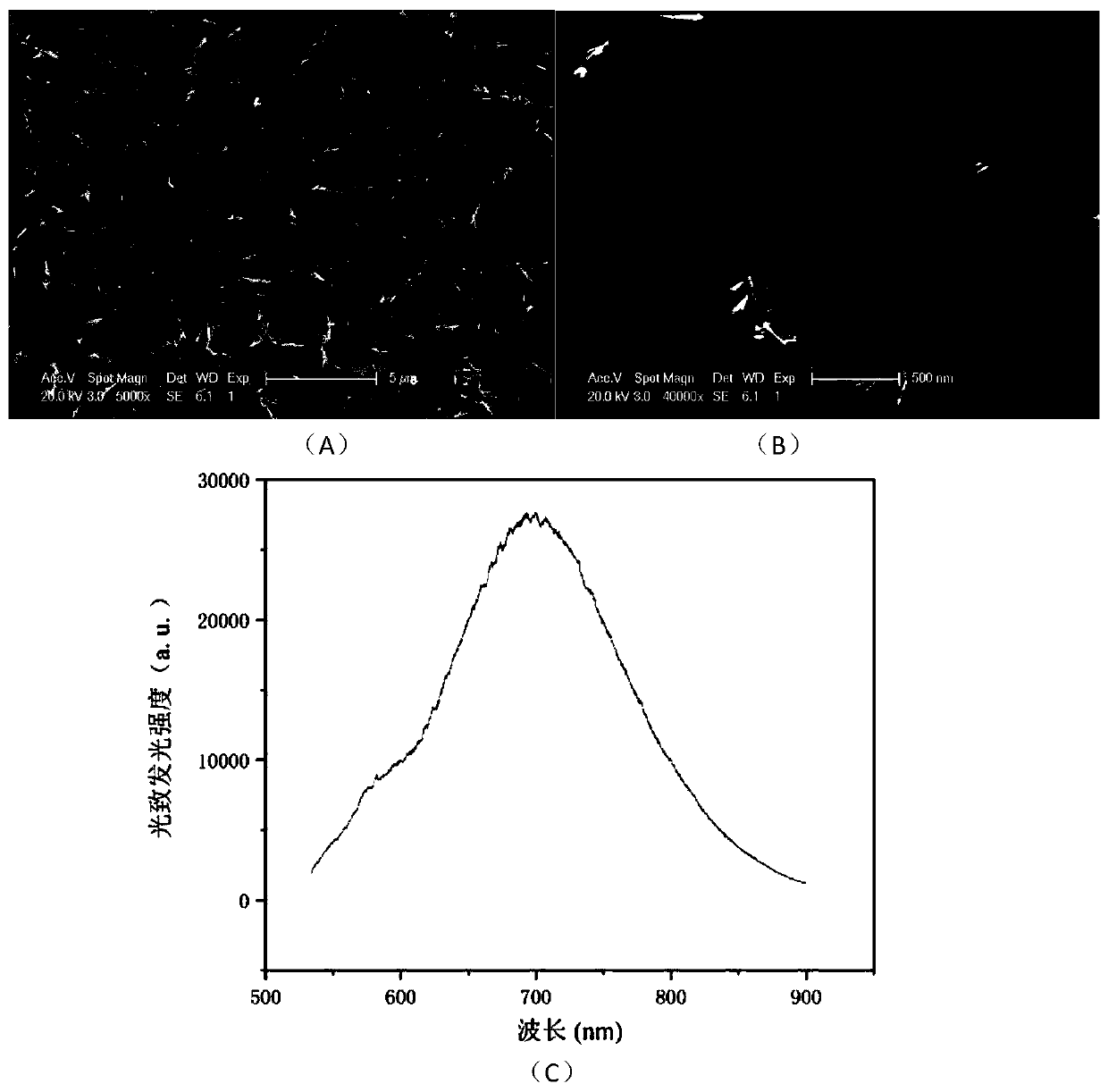

[0034] Scanning electron microscope images (SEM) show the Zn-doped cuprous oxide film as a nan...

Embodiment 2

[0039] Replace the "zinc ion-thiocyanate" aqueous solution with zinc sulfate aqueous solution.

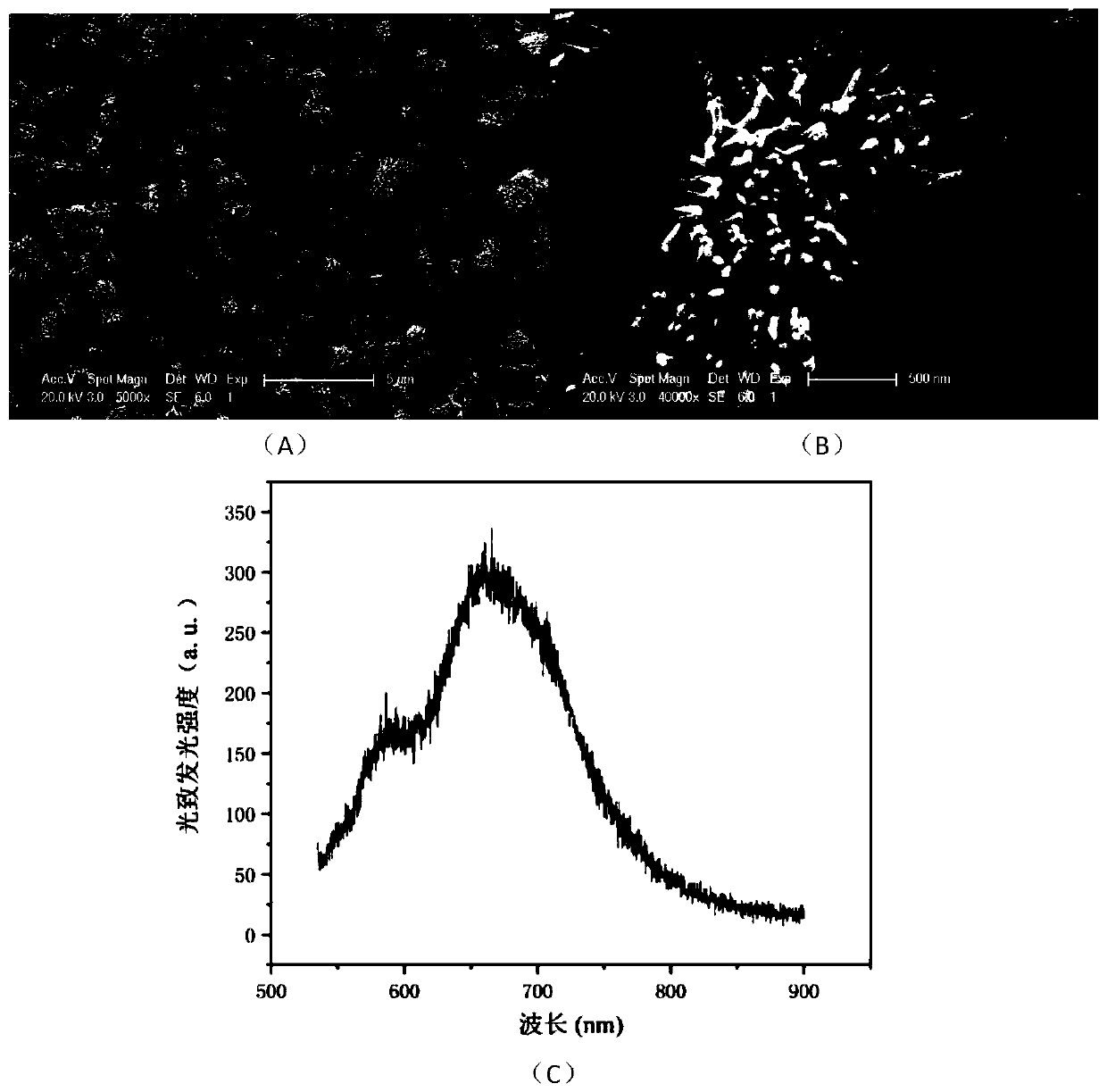

[0040] The cuprous thiocyanate film is immersed in zinc sulfate aqueous solution for adsorption, and then reacted with alkali solution to prepare zinc-doped cuprous oxide film. The experimental steps are similar, but the aggregation form and photoluminescent properties of the products are significantly different.

[0041] SEM images such as figure 2 (A) and 2(B). The film can emit light under the excitation of green light (532 nm), but the luminous intensity is significantly reduced, and the emission wavelength also shifts, such as figure 2 (C) shown.

[0042] This example shows that in the process of preparing zinc-doped cuprous oxide film, the "zinc ion-thiocyanate" aqueous solution is very different from the general inorganic salt solution (such as zinc sulfate aqueous solution).

[0043] This example further proves that the "metal ion-thiocyanate" aqueous solution has unu...

Embodiment 3

[0045] The commercially available cuprous thiocyanate powder was ground into a very fine powder to replace the cuprous thiocyanate film in Example 1 to prepare zinc-doped cuprous oxide nanomaterials.

[0046] A zinc-doped cuprous oxide powder sample was obtained, which was similar to the product in Example 1 and had a nanowire structure.

[0047] Many kinds of zinc-doped cuprous oxide nanomaterials can be prepared by changing the experimental formula, including the amount of thiocyanate and the concentration of the solution.

[0048] This kind of zinc-doped cuprous oxide nanomaterials can be used as one of the three primary colors to construct white light-emitting devices (LEDs), which is a new type of phosphor. It can also be used as an antifouling coating additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com