Blue-excited red fluorescent material and preparation method thereof

A technology excited by red fluorescence and blue light, which is applied in the field of red fluorescent materials and preparations, can solve problems such as poor stability, high cost, and easy deliquescence, and achieve good stability, no need for coating treatment, and not easy to deliquescence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

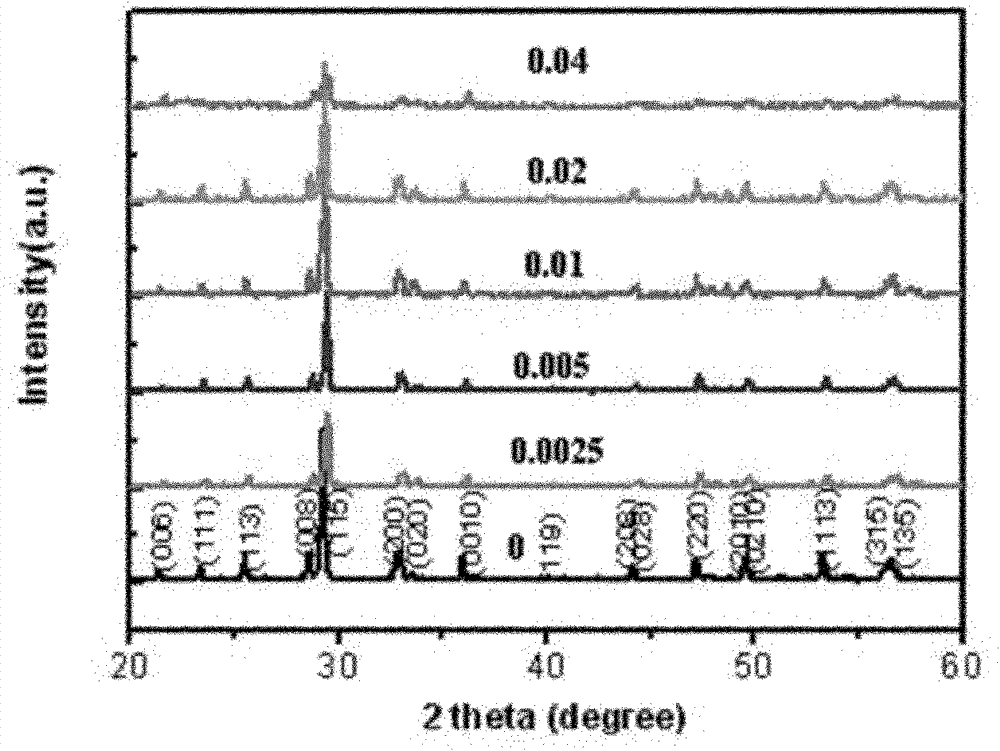

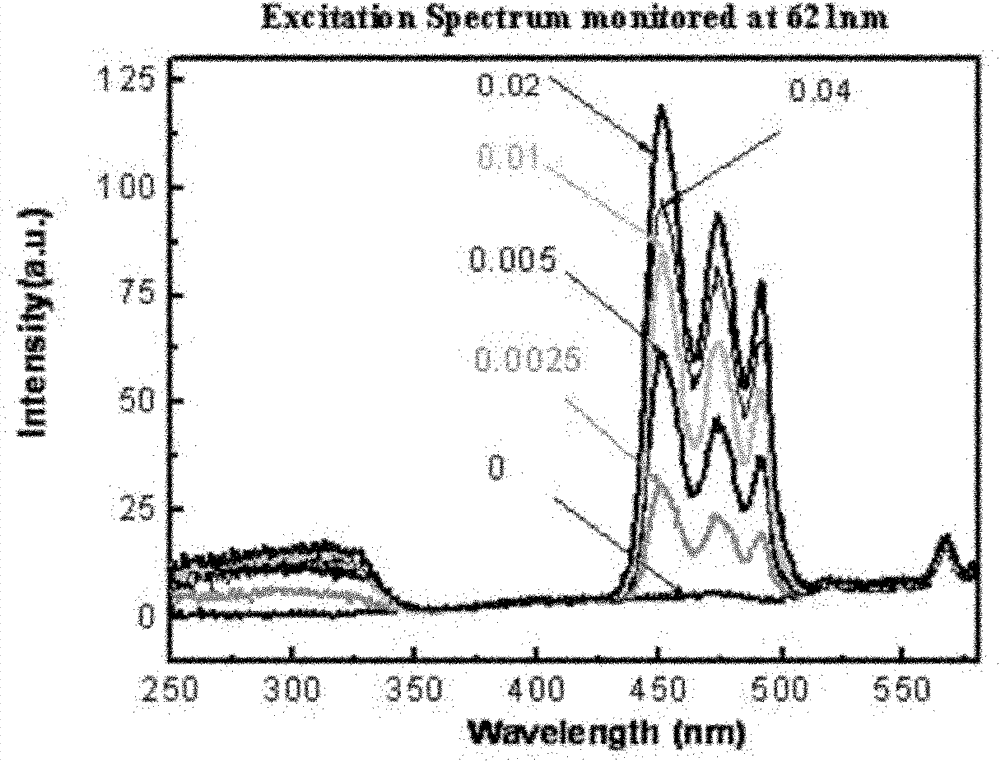

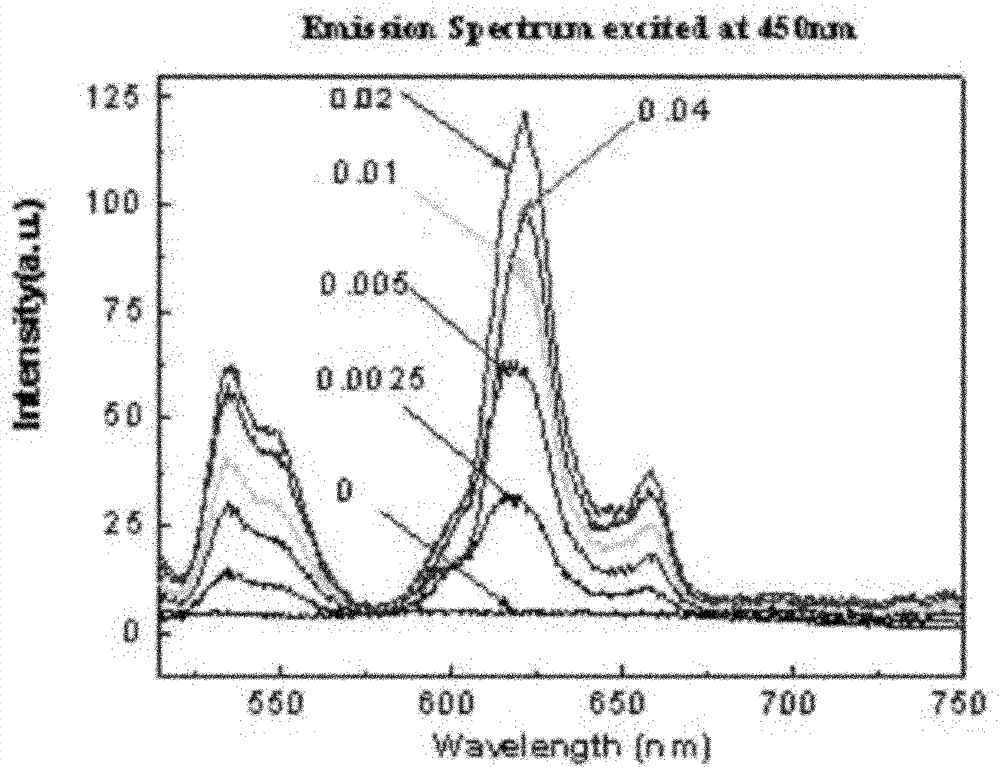

[0031] to prepare Ca 0.9975 Pr 0.0025 Bi 2 Ta 2 O 9 , Ca 0.995 Pr 0.005 Bi 2 Ta 2 O 9 , Ca 0.99 Pr 0.01 Bi 2 Ta 2 O 9 , Ca 0.98 Pr 0.02 Bi 2 Ta 2 O 9 and Ca 0.96 Pr 0.04 Bi 2 Ta 2 O 9 For example, the raw material is CaCO 3 , Pr 6 O 11 , Bi 2 O 3 and Ta 2 O 5 , according to formula Ca 0.9975 Pr 0.0025 Bi 2 Ta 2 O 9 , Ca 0.995 Pr 0.005 Bi 2 Ta 2 O 9 , Ca 0.99 Pr 0.01 Bi 2 Ta 2 O 9 , Ca 0.98 Pr 0.02 Bi 2 Ta 2 O 9 and Ca 0.96 Pr 0.04 Bi 2 Ta 2 O 9 Element ratio Weigh the selected raw materials, add anhydrous ethanol after weighing the raw materials, grind in a mortar and mix thoroughly to obtain powder A 1 , A 2 , A 3 , A 4 and A 5 . Powder A 1 , A 2 , A 3 , A 4 and A 5 They were placed in alumina crucibles for pre-sintering, the pre-sintering temperature was 850°C, the heating rate was 3°C / min, and the pre-sintering powder B was obtained after holding for 2 hours and naturally cooling. 1 , B 2 , B 3 , B 4 and B ...

Embodiment 2

[0040] to prepare Ca 0.9975 Sm 0.0025 Bi 2 Ta 2 O 9 For example, the raw material is CaCO 3 , Sm 2 O 3 , Bi 2 O 3 and Ta 2 O 5 According to formula Ca 0.9975 Sm 0.0025 Bi 2 Ta 2 O 9The selected raw materials were weighed for the element ratio, and the remaining experimental conditions were the same as those in Example 1.

[0041] The detection shows that the final sample obtained in this example emits red fluorescence after being excited by blue light, and the main excitation peak position of the phosphor powder is 480 nm, and the main emission peak position is 602 nm.

Embodiment 3

[0043] to prepare Ca 0.995 Sm 0.0025 Eu 0.0025 Bi 2 Ta 2 O 9 For example, the raw material is CaCO 3 , Eu 2 O 3 , Sm 2 O 3 , Bi 2 O 3 and Ta 2 O 5 According to formula Ca 0.9975 Eu 0.0025 Bi 2 Ta 2 O 9 The selected raw materials were weighed for the element ratio, and the remaining experimental conditions were the same as those in Example 1.

[0044] The detection shows that the final sample obtained in this example emits red fluorescence after being excited by blue light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com