Monocrystalline silicon with photoluminescent characteristics and preparation method thereof

A photoluminescence and single crystal silicon technology, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of reduced luminous efficiency, destruction, and no luminescence of devices, and achieves simple preparation method, wide application prospect and high luminous efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Using oriented monocrystalline silicon wafer as raw material, its resistivity ρ=1~20Ω / m, thickness T=490±10μm, such as figure 1 Shown is the optical micrograph of the polished surface of single crystal silicon before HCPEB bombardment. The polished surface was used as the bombarded surface during the preparation process. It can be seen from the figure that the surface to be bombarded is smooth and basically free of impurities.

[0032] Use Gatan601 type ultrasonic to cut the above-mentioned single crystal silicon wafer into test samples with a size of 2cm×1cm, put the test samples in alcohol-acetone solution (1:1) and ultrasonically clean them for 10min, take them out and dry them with nitrogen before use. The above cleaned and dried single crystal silicon sample is placed in an electron beam emission device, and the surface of the single crystal silicon is subjected to electron beam pulse bombardment treatment. During the pulse bombardment treatment on the surface of t...

Embodiment 2

[0038]Using oriented single crystal silicon wafer as raw material, its resistivity ρ=30~50Ω / m, thickness T=500±10μm, the above single crystal silicon wafer is cut into 2cm×1cm size by Gatan601 ultrasonic wave For the test sample, place the test sample in an alcohol-acetone solution (1:1) and ultrasonically clean it for 10 minutes, take it out and blow it dry with nitrogen before use, and place the single crystal silicon sample after the above cleaning and drying in the electron beam emission device. Electron beam pulse bombardment treatment is performed on the surface of single crystal silicon.

[0039] In the pulse bombardment treatment of the surface of a single crystal silicon sample, the electron beam energy of the HCPEB emission device is 21.6~27KeV, the number of bombardments is 1~30, and the vacuum degree P≤8×10 -3 Pa, the distance L=6cm between the single crystal silicon sample and the cathode electron gun.

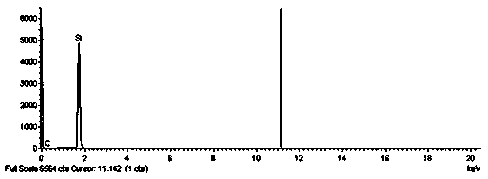

[0040] The photoluminescence (PL) characteristics of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com