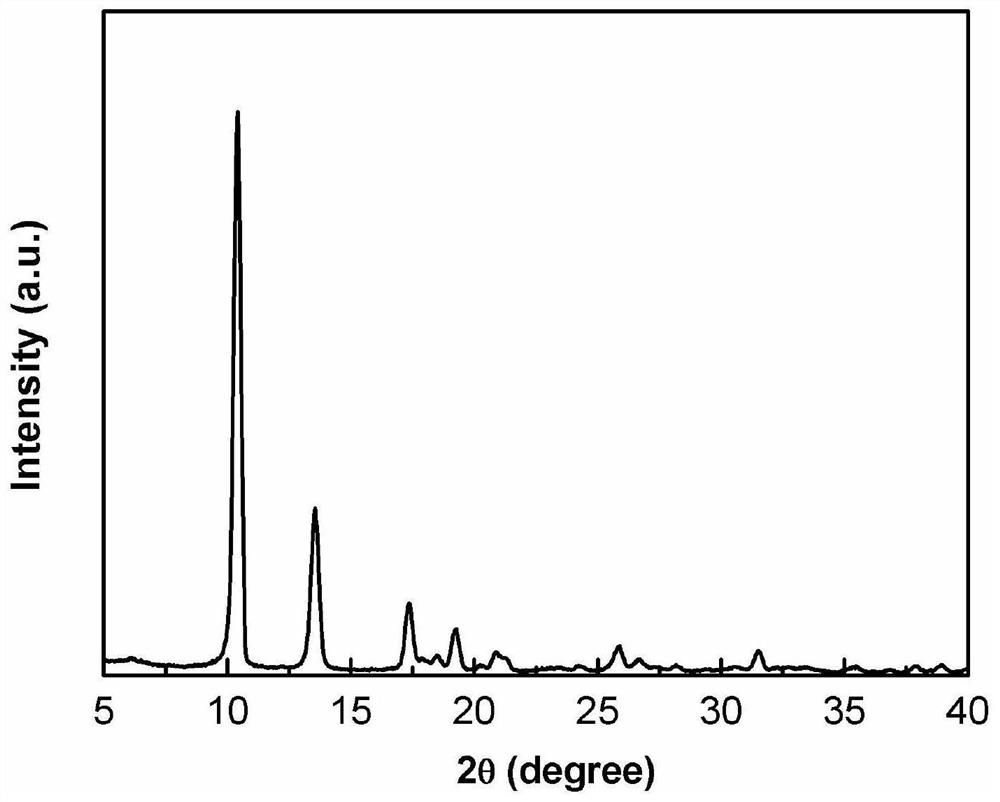

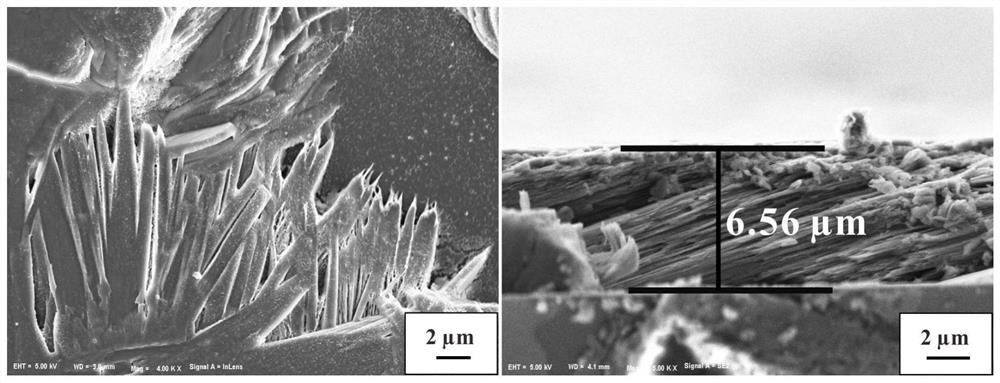

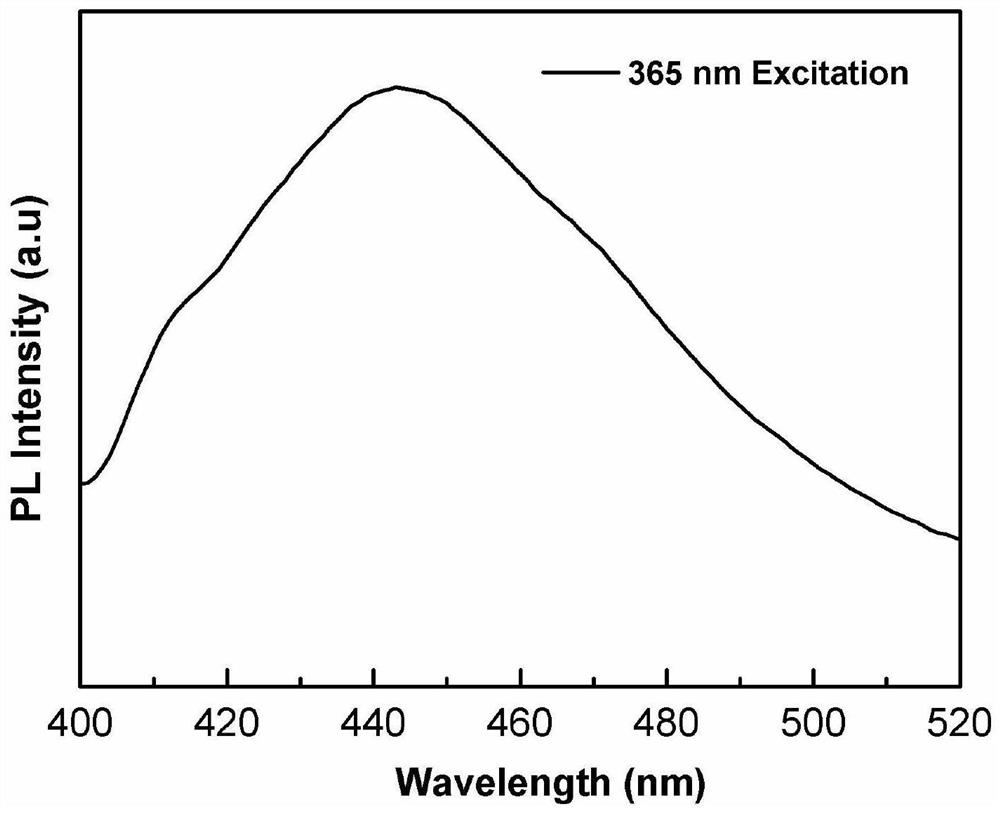

A kind of preparation method of layered stack photoluminescence zif-l film structure

A technology of ZIF-L and photoluminescence, which is applied in the field of materials, can solve complex problems and achieve the effects of low equipment requirements, low cost, good repeatability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of ZIF-L sol (the molar ratio of reactants is 1:1 and the ratio of 2-methylimidazole to solvent is 0.025mol:5ml): Weigh 5.4878g of zinc acetate dihydrate and 2.0525g of 2-methylimidazole respectively Imidazole is placed in a small glass bottle equipped with a magnet, then 5ml of methanol is added to the glass bottle, and the glass bottle is placed on a magnetic stirrer to mix and stir for 30 minutes to obtain ZIF- L-sol.

[0032] (2) Cleaning of thin film substrate: In order to avoid the weak luminescence of the substrate from affecting the photoluminescence performance of the ZIF-L film, the substrate used in the present invention is sapphire. The specific cleaning step is to use deionized water and alcohol solution to sonicate the sapphire for 20 minutes.

[0033] (3) Spin-coating coating on the substrate: place the sapphire substrate on the platform of the spin coating apparatus, and evenly coat the ZIF-L sol on the substrate with a dropper, and set ...

Embodiment 2

[0037] (1) Preparation of ZIF-L sol (the molar ratio of reactants is 1:2 and the ratio of 2-methylimidazole to solvent is 0.050mol:30ml): Weigh 5.4878g of zinc acetate dihydrate and 4.1050g of 2-methylimidazole respectively Kimidazole is placed in a small glass bottle equipped with a magnet, then 15ml of methanol is added to the glass bottle, and the glass bottle is placed on a magnetic stirrer to mix and stir for 60 minutes to obtain a concentration of 1.67mol / L. ZIF-L sol.

[0038] (2) Cleaning of thin film substrate: In order to avoid the weak luminescence of the substrate from affecting the photoluminescence performance of the ZIF-L film, the substrate used in the present invention is a standard grade glass slide. The specific cleaning step is to sonicate the glass slide for 40 minutes with deionized water and alcohol solution in sequence.

[0039] (3) Spin-coating coating on the substrate: place the glass slide substrate on the platform of the spin coating apparatus, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com