Preparation method of graphene/polyaniline covalent binding conductive fabric

A technology of covalent bonding and flexible conduction, which is applied in the direction of plant fibers, animal fibers, textiles and papermaking, etc., can solve the problems of not very strong conductivity, poor heat resistance and stability, etc., and achieve easy operation, simple technical solutions, and broad The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

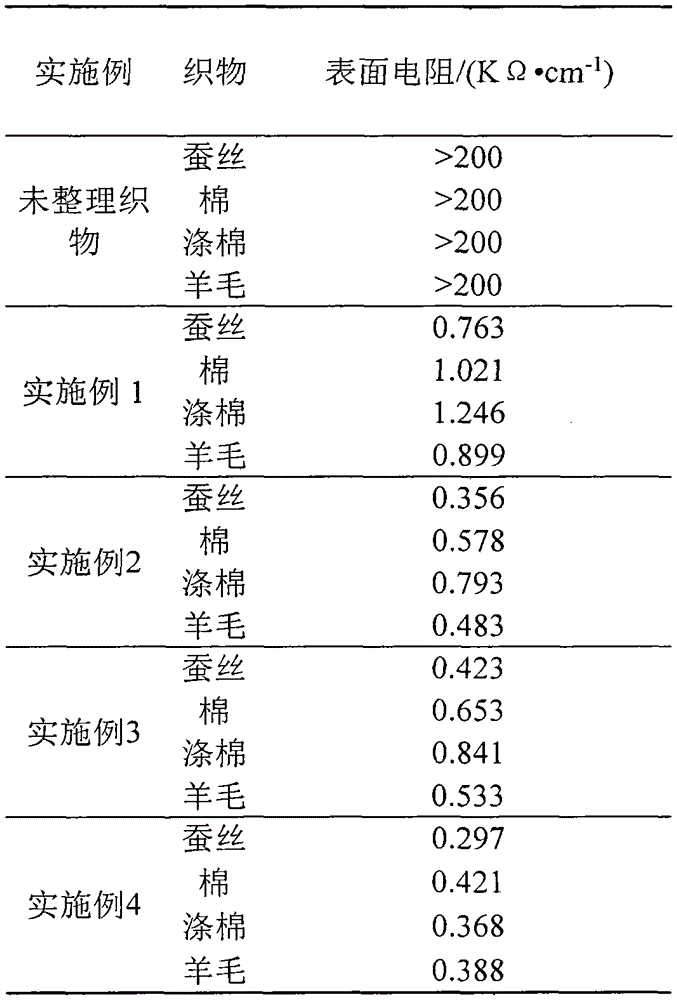

Examples

Embodiment 1

[0021] A kind of preparation method of graphene / polyaniline covalently combining flexible conductive fabric, its process is as follows:

[0022] (1) Prepare a uniform mixed solution of graphene oxide and anionic surfactant: add 0.2 mass parts of anionic surfactant and 0.1 mass part of sulfuric acid into the graphene oxide of 0.4 mass parts, at 40 ℃, 800W Ultrasonic reaction under power for 1h, to obtain a uniform mixed solution of graphene oxide or its derivatives and anionic surfactant;

[0023] (2) p-Phenylenediamine grafted graphene oxide or its derivatives: 0.12 parts by mass of p-phenylenediamine and 0.06 parts by mass of thionyl chloride were added to the solution obtained in (1), at 50 ° C under nitrogen Reaction 4h under the protection of p-phenylenediamine grafted graphene oxide or its derivatives;

[0024] (3) Preparation of fabrics grafted with p-phenylenediamine-reduced graphene oxide: immerse the fabrics in the solution obtained in (2), the immersion temperature ...

Embodiment 2

[0027] A kind of preparation method of graphene / polyaniline covalently combining flexible conductive fabric, its process is as follows:

[0028] (1) prepare the homogeneous mixed solution of carboxylated graphene oxide and anionic surfactant: the anionic surfactant of 0.1 mass part, the sulfuric acid of 0.2 mass part, join in the carboxylated graphene oxide of 0.3 mass part, in Ultrasonic reaction at 30°C and 500W power for 2 hours to obtain a uniform mixed solution of carboxylated graphene oxide or its derivatives and anionic surfactant;

[0029] (2) p-Phenylenediamine grafted with carboxylated graphene oxide: add 0.08 parts by mass of p-phenylenediamine and 0.04 parts by mass of thionyl chloride to the solution obtained in (1), and place it under the protection of nitrogen at 70 ° C. After reacting for 3h, p-phenylenediamine grafted carboxylated graphene oxide or its derivatives are obtained;

[0030] (3) Preparation of the fabric of carboxylated graphene oxide grafted with...

Embodiment 3

[0033] A kind of preparation method of graphene / polyaniline covalently combining flexible conductive fabric, its process is as follows:

[0034] (1) Prepare a uniform mixed solution of sulfonated graphene oxide and anionic surfactant: the anionic surfactant of 0.15 mass parts, the sulfuric acid of 0.15 mass parts, join the sulfonated graphite oxide of 0.4 mass part ene, ultrasonic reaction at 40°C and 800W power for 1.5h, to obtain a uniform mixed solution of sulfonated graphene oxide or its derivatives and anionic surfactant;

[0035] (2) p-Phenylenediamine grafted sulfonated graphene oxide: 0.13 parts by mass of p-phenylenediamine and 0.06 parts by mass of thionyl chloride were added to the solution obtained in (1), at 60 ° C under nitrogen Reaction for 8h under the protection of p-phenylenediamine grafted sulfonated graphene oxide or derivatives thereof;

[0036] (3) Preparation of the fabric of sulfonated graphene oxide grafted with p-phenylenediamine: immerse the fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com