Nano composite material as well as preparation method and application thereof to water treatment

A nano-composite material and nano-particle technology, applied in the field of functional materials, can solve problems such as restricting application and endangering human health, and achieve the effect of increasing saturated adsorption capacity and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing the nanocomposite material described in the above technical solution, comprising the following steps:

[0034] (1) mixing the matrix material with water-soluble ferrous salt, water-soluble ferric salt, water-soluble magnesium salt and water to obtain a mixed solution;

[0035] (2) adding alkali solution dropwise to the mixed solution obtained in the step (1), and performing a precipitation reaction to obtain a nanocomposite material.

[0036] In the invention, the matrix material is mixed with water-soluble divalent iron salt, water-soluble ferric salt, water-soluble magnesium salt and water to obtain a mixed solution. In the present invention, the mass concentration of the matrix material in the mixed solution is preferably 0.1-5%, more preferably 0.5-4%, and most preferably 1-3%. In the present invention, Fe in the mixed solution2+ with Fe 3+ The total concentration of is preferably 0.05-5 mol / L, more prefer...

Embodiment 1

[0050] In a 250mL beaker, add 90mL distilled water, 3.2gMg(NO 3 ) 2 ·6H 2 O, 1.2g FeSO 4 ·7H 2 O, 2.2 g FeCl 3 ·6H 2 O and 0.05g graphene oxide powder, use a cell disruptor to disperse with a 15KHz ultrasonic wave for 30min, then transfer the mixed dispersion to a 250mL flask. Aqueous ammonia was slowly added dropwise at a rate of mL / min, 10 mL of aqueous ammonia (25 wt%) was added dropwise, and nitrogen gas was continued for 5 minutes. After the system was closed, it was placed in an oil bath at 70°C for 2 hours, and then the temperature was raised to 90°C to continue the reaction for 10 hours. After the reaction, the reaction product was magnetically separated, washed repeatedly with deionized water three times until the pH value of the solution was neutral, and then the product was dried at -90° C. for 48 h using a freeze dryer to obtain a nanocomposite material.

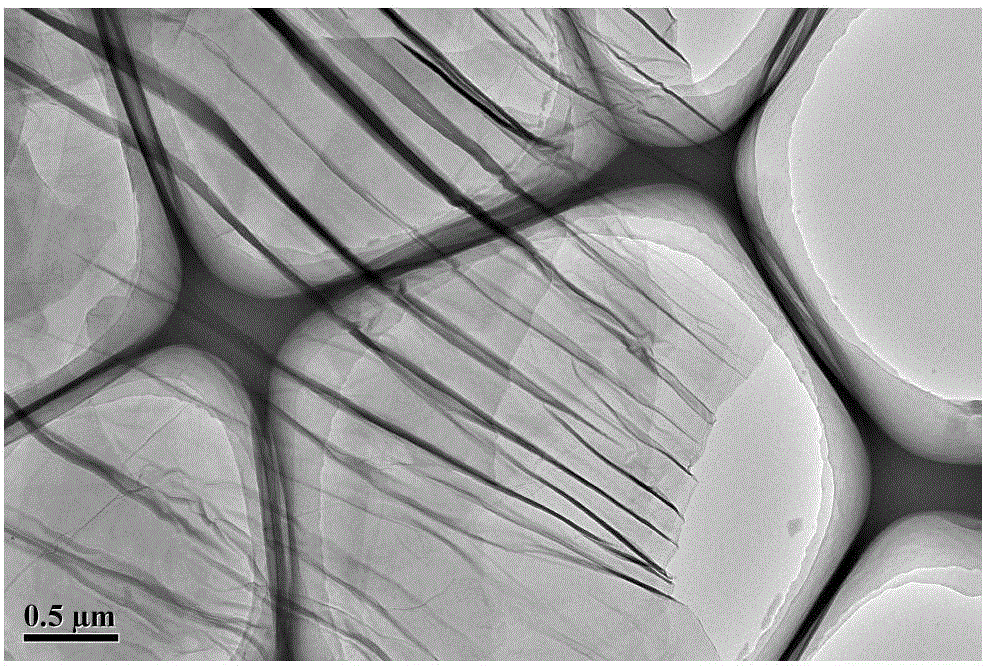

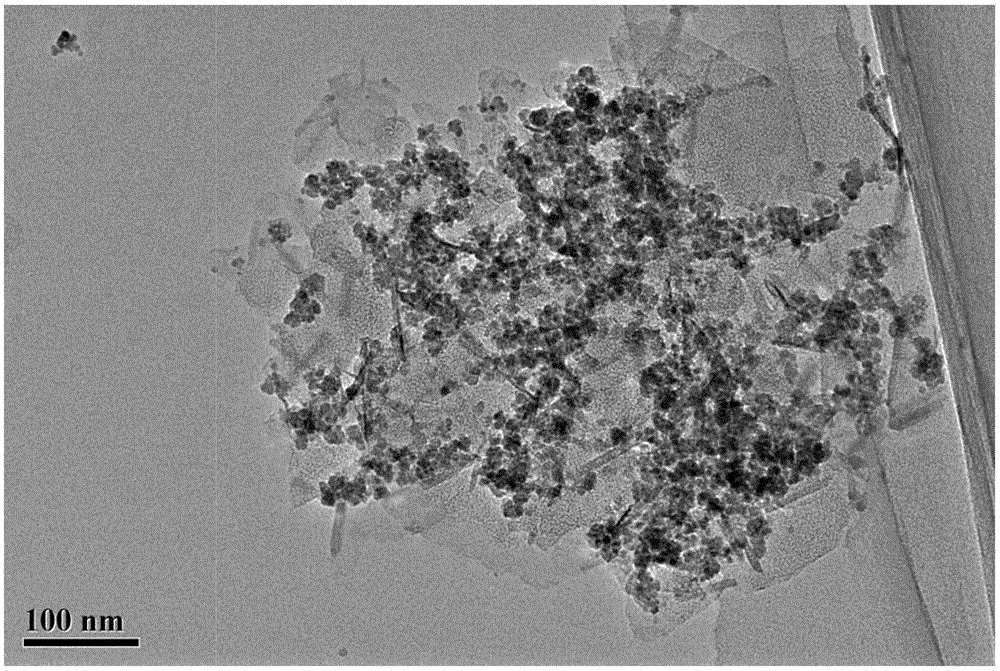

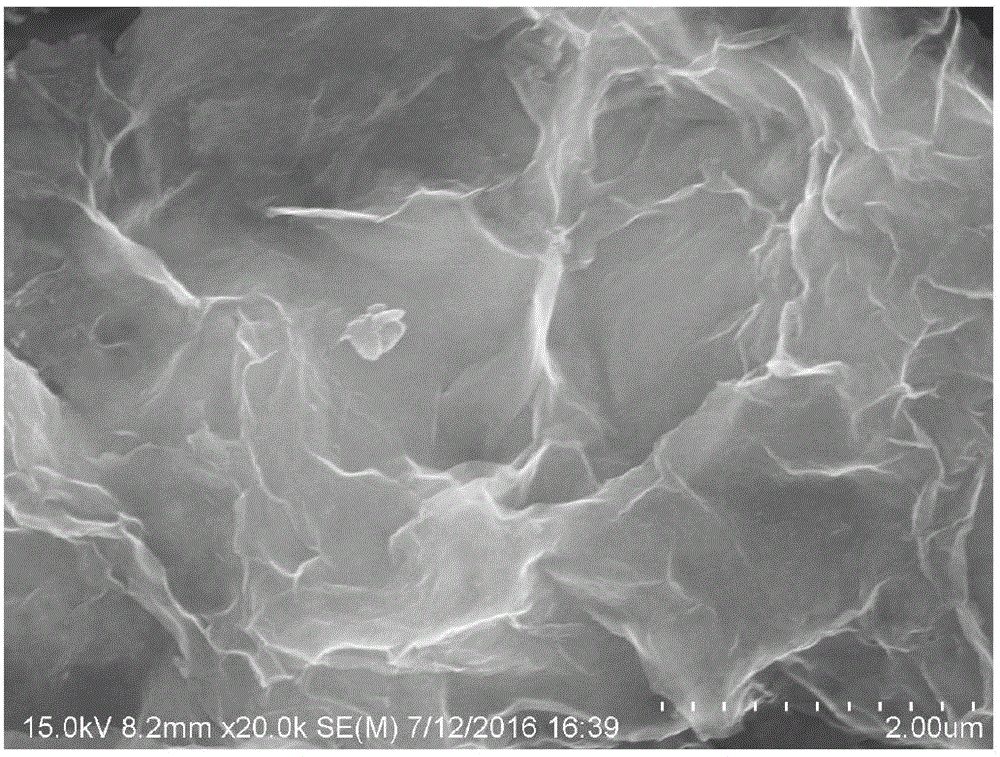

[0051] The graphene oxide used in this embodiment and the TEM photographs of the nanocomposite material...

Embodiment 2

[0053] Take 0.1g of the nanocomposites prepared in Example 1 respectively, place them in 100mL of PB 2+ Solution, Cu 2+ solution, Ag + solution, Zn 2+ In the solution, use magnetic force to stir for 12 hours, measure with inductively coupled plasma emission spectrometer, because the loaded inorganic particles chelate with the above-mentioned heavy metal ions, the pb 2+ The concentration can be reduced from 98.74ppm before adsorption to 0.0075ppm after adsorption, Cu 2+ The concentration can be reduced from 60.78ppm before adsorption to 0.0052ppm after adsorption, Ag + The concentration can be reduced from 32.93ppm before adsorption to 0.001ppm after adsorption, Zn 2+ The concentration can be reduced from 42.92ppm before adsorption to 0.044ppm after adsorption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com