Modified graphene oxide, engine lubricating oil and application thereof

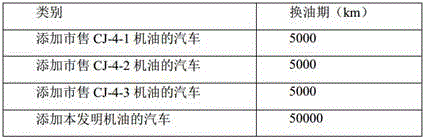

A technology of stone oxide and graphene, applied in the field of lubricating oil, can solve problems such as difficult to open, unstable dispersion, poor compatibility, etc., to achieve the effects of reducing impact, saving fuel, and extending the oil change period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

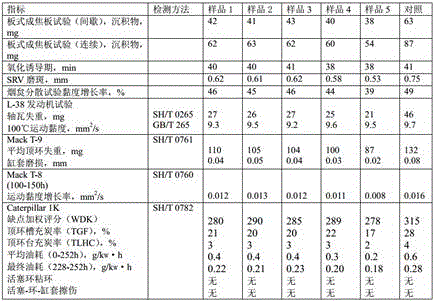

Examples

preparation example Construction

[0042] The preparation method of this modified graphene oxide mainly uses the graphene oxide prepared by the improved Hummer method as a precursor, and uses long-chain aliphatic amines, organosilicon, etc. to modify it under different reaction conditions by solvothermal method. In the present invention, dodecylamine, tetradecylamine, hexadecylamine, octadecylamine (ODA), hexadecyltrimethoxysilane, gamma-methacryloxypropyltrimethoxy Silane (KH-570) etc. modified graphene oxide to prepare functionalized graphene oxide.

[0043] Graphene oxide prepared by the improved Hummers method described in the present invention can be prepared by the method disclosed in the known technology, for example as follows: 1) 1g of natural graphite, concentrated H 2 SO 4 、H 3 PO 4 The three are placed in a three-necked flask, and concentrated H 2 SO 4 with H 3 PO 4 The volume ratio of the solution was 9:1, and 6 g of potassium permanganate was added in portions, and stirred in an ice-water b...

Embodiment 1

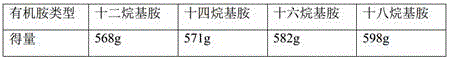

[0065] Embodiment 1 preparation of long-chain aliphatic amine modified graphene

[0066] Dissolve 500g of different long-chain fatty amines (dodecylamine, tetradecylamine, hexadecylamine, octadecylamine) in 50L of 95v / v% ethanol, and ultrasonically disperse for 1 hour , made into a homogeneous solution, and quickly poured it into a stainless steel reaction kettle containing 50L of 10mg / mL graphene oxide (GO) aqueous solution with a polytetrafluoroethylene liner, heated at 100°C, reacted for 2h, and then cooled naturally to At room temperature, filter out the reaction solid, use ethanol as a solvent to mix with the solid, centrifuge the product at 9000r / min for 30min, repeat the centrifugation three times to remove unreacted organic amine, vacuum filter the product, and rinse with a large amount of deionized water Three times, the filter cake was dried overnight at 30°C under vacuum, and finally a light black powder long-chain aliphatic amine-modified graphene oxide was obtaine...

Embodiment 2

[0070] The difference from Example 1 is that in the modification of graphene oxide, a silane coupling agent γ-methacryloxypropyltrimethoxysilane (KH-570) was also added.

[0071] Dissolve 500g of octadecylamine and 50g of KH570 in 50L of 95v / v% ethanol, ultrasonically disperse for 1 hour to make a homogeneous solution, and quickly pour it into 50L of 10mg / mL graphene oxide (GO) The aqueous solution was heated at 100°C in a stainless steel reaction kettle lined with polytetrafluoroethylene, reacted for 2 hours, and then naturally cooled to room temperature, filtered out the solids of the reaction, mixed with ethanol as a solvent, and the product was heated at 9000r / min Centrifuge at low temperature for 30 minutes, repeat the centrifugation three times to remove unreacted organic amine, vacuum filter the product, and wash it three times with a large amount of deionized water, dry the filter cake at 30°C in vacuum overnight, and finally obtain a light black powder modified with oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com