Preparation method of graphene/polyaniline self-assembly flexible conductive fabric

A flexible conductive and graphene technology, applied in the directions of plant fibers, animal fibers, textiles and papermaking, can solve problems such as unreachable, fabric comfort effects, low conductive functions, etc., to achieve easy operation, simple technical solutions, and broad The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

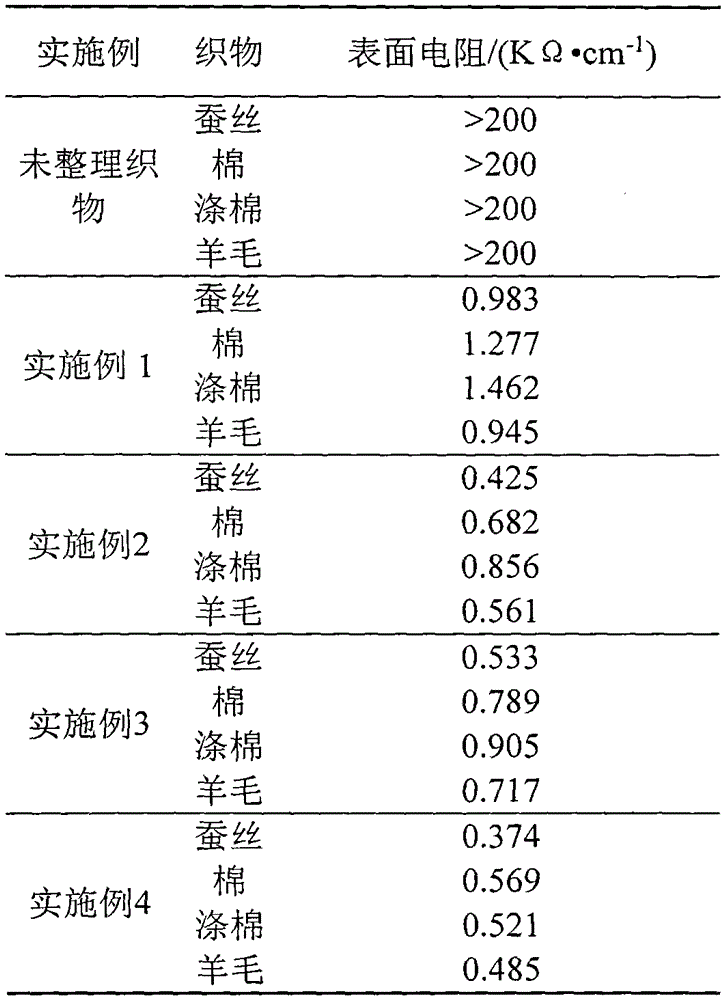

Examples

Embodiment 1

[0016] A kind of preparation method of graphene / conductive polymer self-assembled flexible conductive fabric, its process is as follows:

[0017] Prepare a 0.2% aqueous solution of graphene oxide, adjust the pH to 4 with acetic acid-sodium acetate buffer solution, immerse the fabric in the above solution, the immersion temperature is 30°C, and the immersion time is 1h, then dry the fabric at 80°C for 1h, and dry The fabric is reduced in 0.5% sodium dithionite solution, the reduction temperature is 90°C, the reduction time is 0.5h, and finally washed and dried to obtain a conductive fabric covered with reduced graphene oxide;

[0018] Immerse the conductive fabric covered with reduced graphene oxide into a hydrochloric acid solution containing 0.1% aniline and 1mol / L, the immersion temperature is 20°C, and the immersion time is 18h, and then add 0.5% initiator ammonium persulfate to make the aniline monomer in situ Polymerized into polyaniline to obtain graphene / polyaniline sel...

Embodiment 2

[0020] A kind of preparation method of graphene / conductive polymer self-assembled flexible conductive fabric, its process is as follows:

[0021] Prepare a 0.1% carboxylated graphene oxide aqueous solution, adjust the pH to 5 with acetic acid-sodium acetate buffer solution, immerse the fabric in the above solution, the immersion temperature is 20°C, and the immersion time is 0.5h, and then the fabric is dried at 60°C for 2h, Reducing the dried fabric in 0.3% hydrazine hydrate solution, the reduction temperature is 80°C, the reduction time is 2h, and finally washed with water and dried to obtain a conductive fabric covered with reduced carboxylated graphene oxide;

[0022] Immerse the conductive fabric covered with reduced graphene oxide into the sulfuric acid solution containing 0.03% aniline and 0.5mol / L, the immersion temperature is 30°C, the immersion time is 12h, and then add 0.4% initiator potassium persulfate to make the aniline monomer Polyaniline is polymerized into po...

Embodiment 3

[0025] A kind of preparation method of graphene / conductive polymer self-assembled flexible conductive fabric, its process is as follows:

[0026] Prepare a 0.4% aqueous solution of sulfonated graphene oxide, adjust the pH to 2 with acetic acid-sodium acetate buffer solution, immerse the fabric in the above solution, the immersion temperature is 20°C, the immersion time is 2h, and then the fabric is dried at 50°C for 4h , reducing the dried fabric in 0.8% sodium dithionite solution, the reduction temperature is 85°C, the reduction time is 1h, and finally washed and dried to obtain a conductive fabric covered with reduced graphene oxide;

[0027] Immerse the conductive fabric covered with reduced graphene oxide into a solution containing 0.4% aniline and 1mol / L hydrochloric acid, the immersion temperature is 30°C, the immersion time is 6h, and then add 0.4% initiator ammonium persulfate to make the aniline monomer in situ Polymerized into polyaniline to obtain graphene / polyanili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com