Stone needle complex fiber containing graphene as well as preparation method and application of stone needle complex fiber

A composite fiber and graphene technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of fiber strength reduction, achieve the effect of improving mechanical properties, wide application, and improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

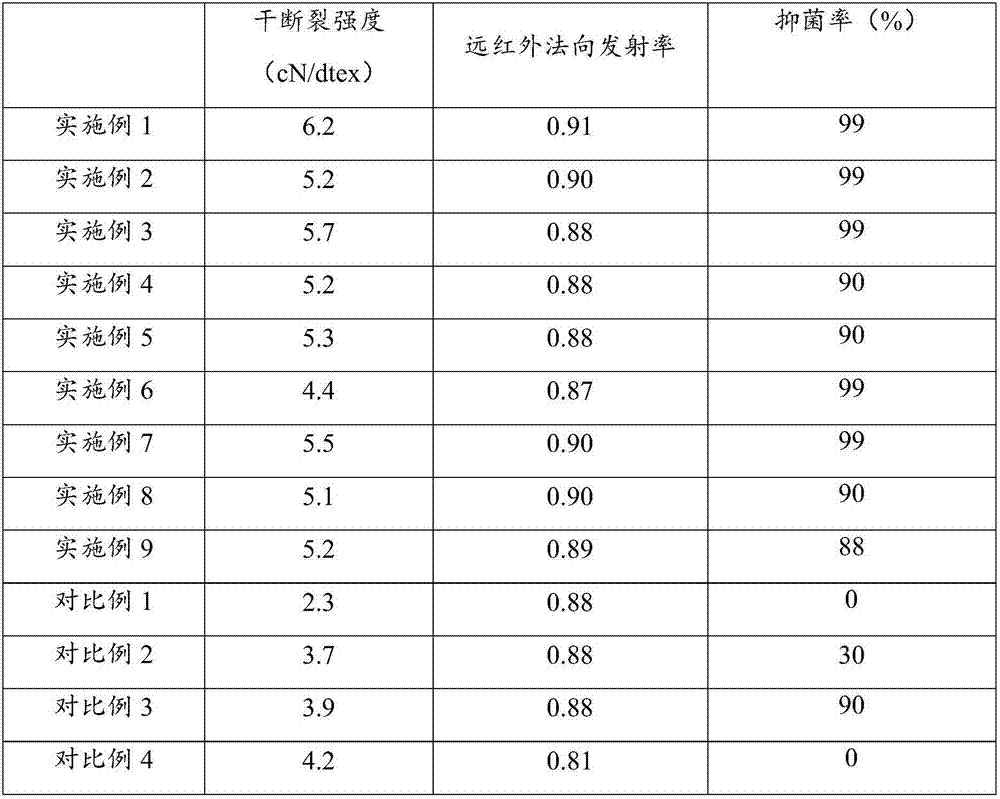

Examples

Embodiment 1

[0064] Taking polyester fiber as an example, prepare a graphene-containing meteorite composite polyester fiber

[0065] Reclaimer:

[0066] 100 grams of polyester chips, 2 grams of meteorites (with a particle size distribution of 0.5 μm to 1 μm), 1.5 grams of graphene B (with a particle size distribution of 0.5 μm to 3 μm), and 0.5 grams of graphene B above 1 μm.

[0067] Prepare masterbatch:

[0068] First, mix the graphene material with a particle size above 1 μm and the meteorite to obtain mixture A; mix the graphene material with a particle size below 1 μm with 1 / 4 polyester chips to obtain mixture B; then mix mixture A and mixture B Mixing and heating, high-speed kneading, twin-screw blending and extrusion, cooling and granulation to obtain masterbatches.

[0069] Spinning:

[0070] The masterbatch is mixed with the remaining polyester chips, spun by melt extrusion, and then post-processed to obtain composite fibers.

Embodiment 2

[0072] The difference with Example 1 is only that the proportioning of raw materials is different, which is:

[0073] 100 grams of polyester chips, 3 grams of meteorites (with a particle size distribution of 0.5 μm to 1 μm), 3 grams of graphene B (with a particle size distribution of 0.5 μm to 3 μm), and 1 gram of graphene B with a particle size of more than 1 μm.

Embodiment 3

[0075] The difference with Example 1 is only that the proportioning of raw materials is different, which is:

[0076] 100 grams of polyester chips, 1 gram of meteorites (with a particle size distribution of 0.5 μm to 1 μm), 0.5 grams of graphene B (with a particle size distribution of 0.5 μm to 3 μm), and 0.25 grams of graphene B above 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com