Composite graphene ion exchange membrane for flow battery and preparation method thereof

An ion-exchange membrane and graphene composite technology, which is applied in the field of graphene composite ion-exchange membranes for flow batteries and their preparation, can solve problems such as poor ion selectivity or poor stability, and achieve low cost, stable battery performance, and improved stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

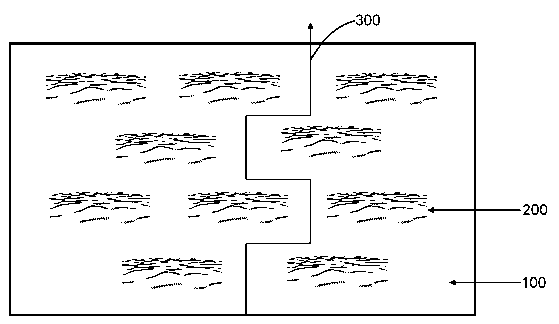

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned graphene composite ion exchange membrane, the method adopts the following steps and process conditions to prepare:

[0036] (1) The above-mentioned sulfonated polymer is added to the organic solvent according to the mass percentage of 1~80 wt%, at 20~100 oUltrasonic dispersion and / or magnetic stirring at C for 0.5-48 hours to prepare a sulfonated polymer solution. The magnetic stirring method can also be replaced by other methods, as long as the polymer can be uniformly dispersed.

[0037] (2) The above-mentioned graphene and / or graphene derivatives are mixed in a mass-volume ratio of 0.001-5 mg mL -1 Added to the organic solvent, at 20~100 o Ultrasonic dispersion and / or magnetic stirring at C for 0.5 to 48 hours to prepare a graphene and / or graphene derivative dispersion.

[0038] (3) Mixing the sulfonated polymer solution obtained in step (1) with the graphene or graphene derivative dispersion obtained in step (2), at 20...

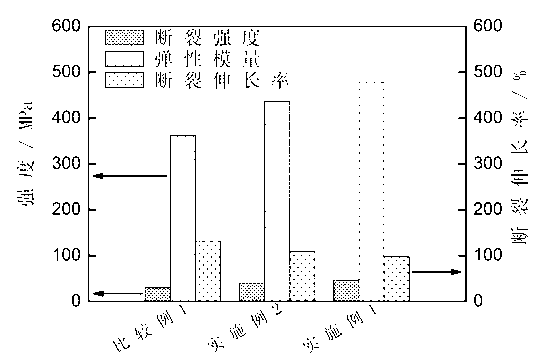

Embodiment 1

[0045] (1) The ion exchange capacity of 1.0 g is 2.10 mmol g -1 Sulfonated polyetheretherketone (SPEEK) was added to 10 mL of N,N-dimethylformamide solvent at 25 o C for ultrasonic dispersion and magnetic stirring for 12 hours to prepare a SPEEK solution.

[0046] (2) Dissolve 1.0 mg of graphene oxide in 5 mL of N,N-dimethylformamide solvent at 25 o C under ultrasonic dispersion, magnetic stirring for 12 hours to prepare a graphene oxide dispersion.

[0047] (3) Mix the SPEEK solution prepared in step (1) with the graphene oxide dispersion prepared in step (2), and o C for ultrasonic dispersion and magnetic stirring for 24 hours to prepare a mixed solution. The mass percentage of graphene oxide in the total solute is 0.1 wt%, and the mass percentage of the total solute in the mixed solution is 6.6 wt%.

[0048] (4) Remove bubbles and impurities from the mixed solution prepared in step (3), and form a film on a horizontal clean glass plate by casting method, successively at...

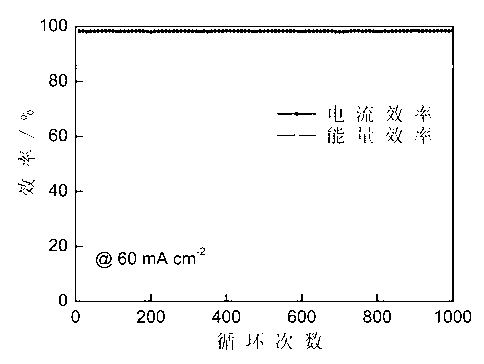

Embodiment 2

[0051] The preparation method of the sulfonated polyether ether ketone-graphene oxide composite ion-exchange membrane of this embodiment 2 is the same as that of embodiment 1, and the graphene oxide content in the prepared sulfonated polyetheretherketone-graphene oxide composite ion-exchange membrane is 0.5 mg, that is, the mass percentage of graphene oxide in the total solute is 0.05 wt%. The thickness of the composite ion exchange membrane is 52 μm. A single cell of an all-vanadium redox flow battery was assembled with this composite ion-exchange membrane, and other assembly conditions and test conditions were the same as in Example 1 (excluding cycle charge-discharge life test). The Coulombic efficiency of the single cell is 97.8%, the voltage efficiency is 85.8%, and the energy efficiency is 83.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com