Graphene modified waterborne epoxy resin coating material as well as preparation method and application thereof

A water-based epoxy resin and graphene modification technology, which is applied in epoxy resin coatings, graphene, anti-fouling/underwater coatings, etc., can solve the problems of unstable dispersion and demulsification of water-based epoxy resin emulsions, and achieve Effects of improving corrosion resistance, improving thermal stability, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

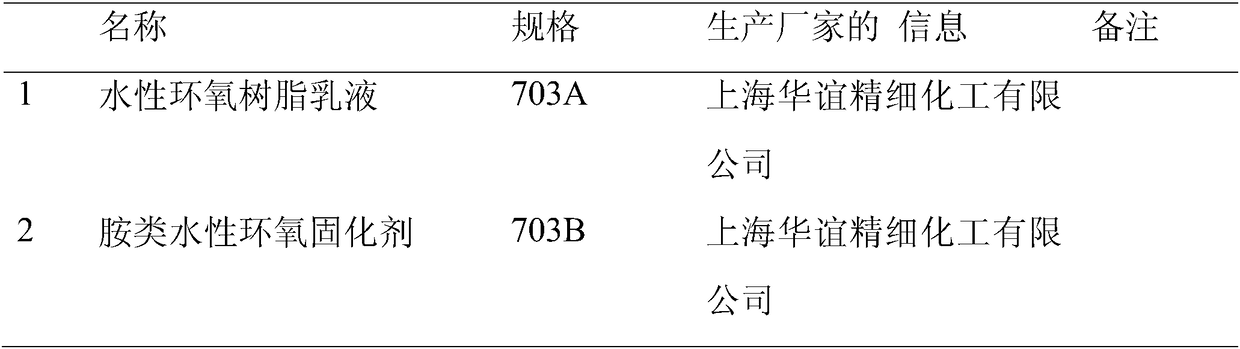

[0049] A graphene-modified water-based epoxy resin coating, composed of A' component with a solid content of 53% and a B component with a solid content of 40%, calculated by mass ratio, that is, A' component: B component is After mixing at a ratio of 3:1, add deionized water and mix well to obtain a graphene-modified water-based epoxy resin coating;

[0050] The adding amount of above-mentioned deionized water is as the criterion to ensure that the solid content in the graphene-modified water-based epoxy resin coating of the final gained is 33%.

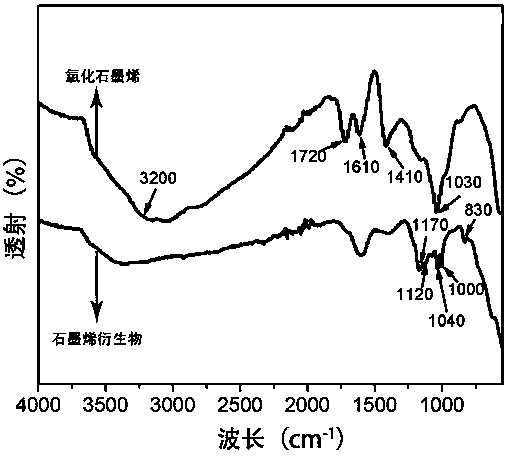

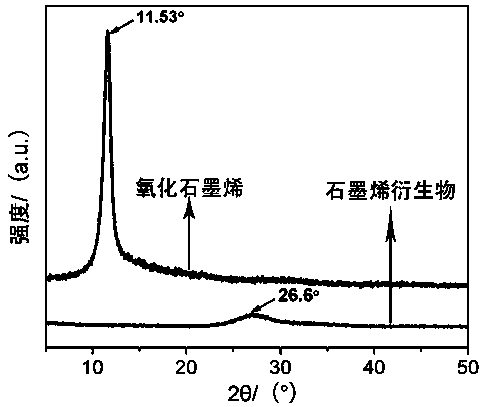

[0051] The A' component is a graphene-modified water-based epoxy resin emulsion. Calculated by mass percentage, add 0.1% graphene derivatives to the water-based epoxy resin emulsion and disperse evenly to obtain graphene-containing derivatives The water-based epoxy resin emulsion is the graphene-modified water-based epoxy resin emulsion;

[0052] Described aqueous epoxy resin emulsion is that bisphenol A epoxy resin obtains through ...

Embodiment 2

[0076] A graphene-modified water-based epoxy resin coating, composed of A' component with a solid content of 53% and a B component with a solid content of 40%, calculated by mass ratio, that is, A' component: B component is After mixing at a ratio of 3:1, add deionized water and mix to obtain a graphene-modified water-based epoxy resin coating;

[0077]The add-on of above-mentioned deionized water is as the criterion to ensure that the solid content in the graphene-modified waterborne epoxy resin coating of final gained is 33%;

[0078] The A' component is a graphene-modified water-based epoxy resin emulsion. Calculated by mass percentage, add 0.2% graphene derivatives to the water-based epoxy resin emulsion and disperse evenly to obtain graphene-containing derivatives The water-based epoxy resin emulsion is the graphene-modified water-based epoxy resin emulsion;

[0079] Described aqueous epoxy resin emulsion is that bisphenol A epoxy resin obtains through emulsifying agent ...

Embodiment 3

[0109] A graphene-modified water-based epoxy resin coating, composed of A' component with a solid content of 53% and a B component with a solid content of 40%, calculated by mass ratio, that is, A' component: B component is After mixing at a ratio of 3:1, add deionized water and mix to obtain a graphene-modified water-based epoxy resin coating;

[0110] The add-on of above-mentioned deionized water is as the criterion to ensure that the solid content in the graphene-modified waterborne epoxy resin coating of final gained is 33%;

[0111] The A' component is a graphene-modified water-based epoxy resin emulsion. Calculated by mass percentage, add 0.5% graphene derivatives to the water-based epoxy resin emulsion and disperse evenly to obtain graphene-containing derivatives. The water-based epoxy resin emulsion is the graphene-modified water-based epoxy resin emulsion;

[0112] Described aqueous epoxy resin emulsion is that bisphenol A epoxy resin obtains through emulsifying agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com