Graphene-based composite electrode material and preparation method thereof

A composite electrode, graphene-based technology, used in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing and other directions, can solve the problem of no ion transport channel, low mass specific capacity, two-dimensional layered material electrode thickness can not be thick, etc. problem, to achieve a good electron transport network and ion transport channels, the effect of increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of graphene composite electrode material of the present invention, it comprises the steps:

[0023] (1) Preparation of graphene matrix.

[0024] The graphite derivative was added into deionized water, and ultrasonically dispersed in an ice-water bath to obtain a graphene derivative solution.

[0025] Preferably, the graphene derivative is selected from graphene oxide.

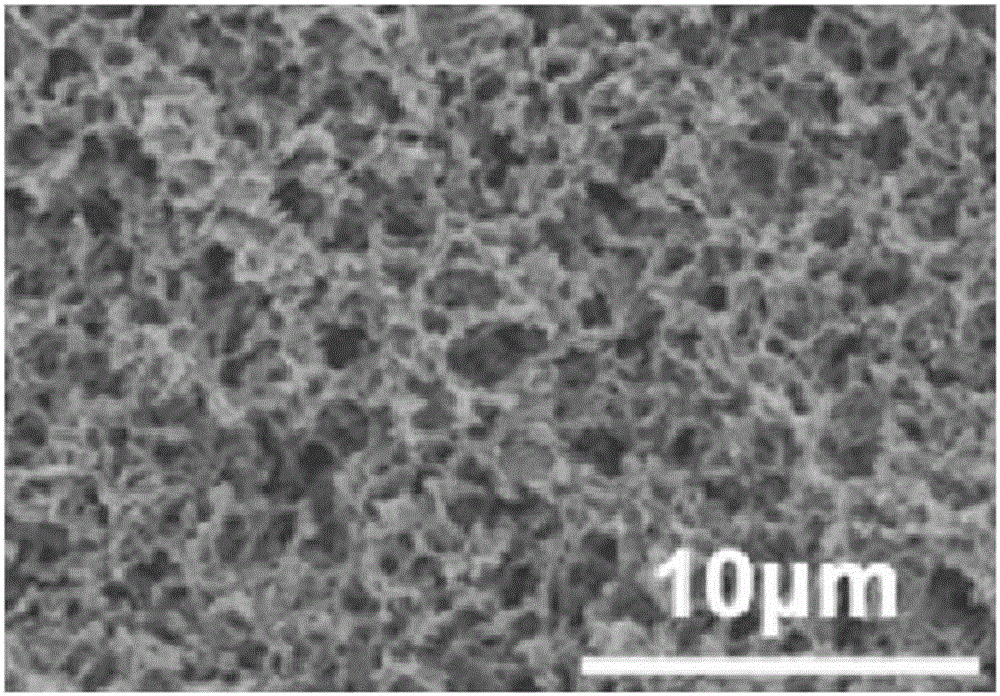

[0026] The ultrasonically dispersed graphene derivative solution is placed in a hydrothermal kettle for hydrothermal treatment to obtain a graphene matrix with a three-dimensional porous structure.

[0027] Those skilled in the art can understand that hydrothermal treatment is conducive to the self-assembly of the sheet structure of graphene derivatives to form a three-dimensional porous network structure, and the graphene matrix thus obtained has a higher specific surface area and a large amount of oxygen. Functional groups, so it is beneficial for the polymer component to adsor...

Embodiment 1

[0059] (1) Preparation of three-dimensional porous graphene matrix.

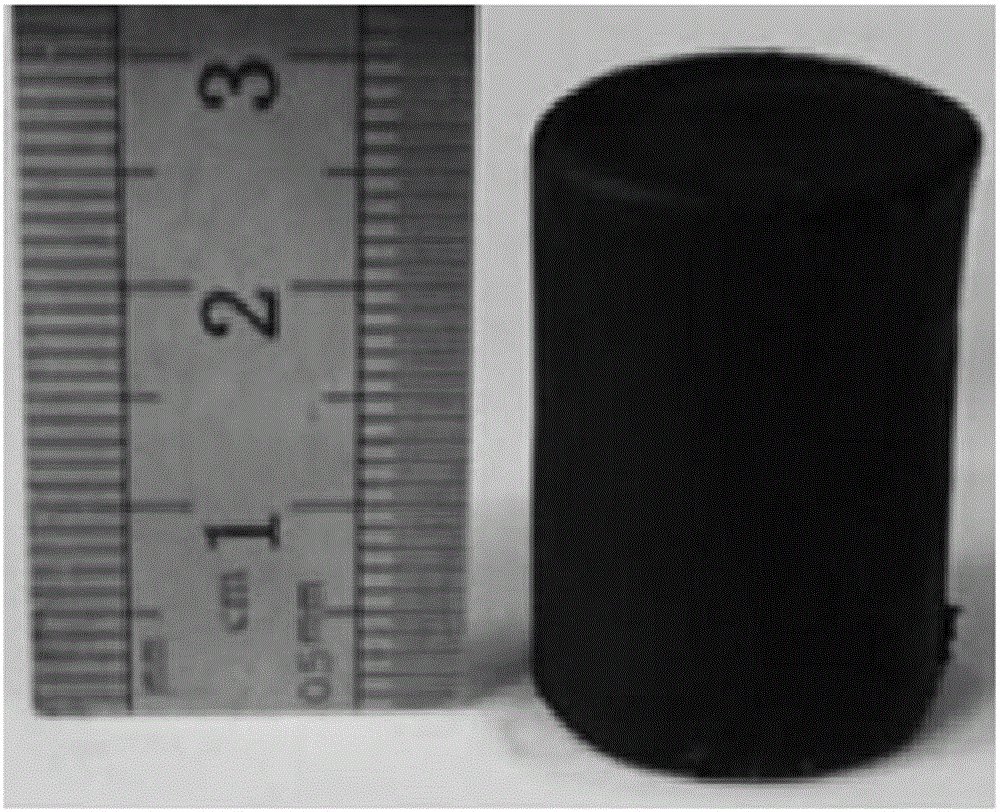

[0060] Weighed 170 mg of graphite oxide and added it to 85 mL of deionized water, and ultrasonically dispersed in an ice-water bath to obtain a 2 mg / mL graphene oxide solution. The uniformly dispersed graphene oxide aqueous solution prepared above was placed in a 100 mL hydrothermal reaction kettle, and then the hydrothermal reaction kettle was placed in a muffle furnace at a temperature of 180° C. for 6 hours to obtain a three-dimensional porous graphene matrix.

[0061] (2) Preparation of graphene / polyaniline composites.

[0062] The graphene substrate prepared by the above reaction was soaked in 20 mL of 1 mol / L hydrochloric acid solution in which aniline monomer was dissolved for 12 hours, and the concentration of the aniline monomer was 0.16 mol / L. Then soak the graphene matrix adsorbed with aniline monomer in a hydrochloric acid solution dissolved with ammonium persulfate and react for 2 hours to obta...

Embodiment 2

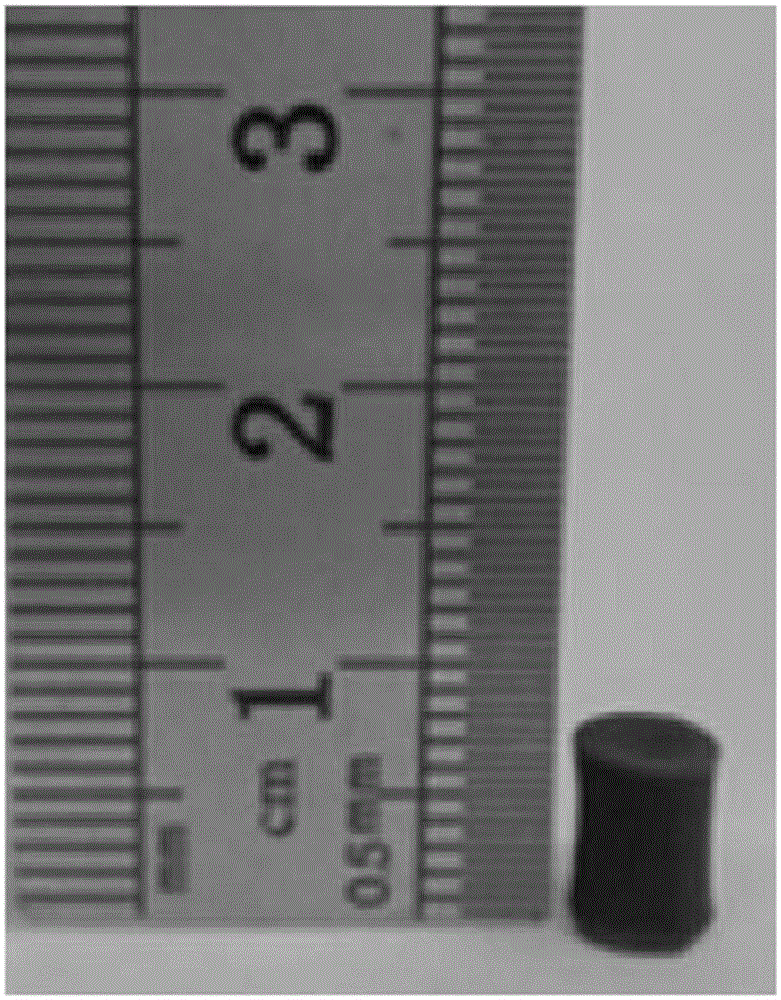

[0067] (1) Preparation of three-dimensional porous graphene matrix.

[0068] Weighed 170 mg of graphite oxide and added it to 85 mL of deionized water, and ultrasonically dispersed in an ice-water bath to obtain a 2 mg / mL graphene oxide solution. The homogeneously dispersed graphene oxide aqueous solution prepared above was placed in a 100 mL hydrothermal reaction kettle, and then the hydrothermal reaction kettle was placed in a muffle furnace at a temperature of 180° C. for 6 hours to obtain a three-dimensional graphene matrix.

[0069] (2) Preparation of graphene / polyaniline composites.

[0070] The graphene substrate prepared by the above reaction was soaked in 1mol / L hydrochloric acid solution dissolved with aniline monomer for 12h, and the concentration of the aniline monomer was 0.013mol / L. Then soak the graphene matrix adsorbed with aniline monomer in a hydrochloric acid solution dissolved with ammonium persulfate and react for 2 hours to obtain a graphene / polyaniline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com