Novel method for recovering solvent for polymerization of poly(p-phenytene terephthalamide)

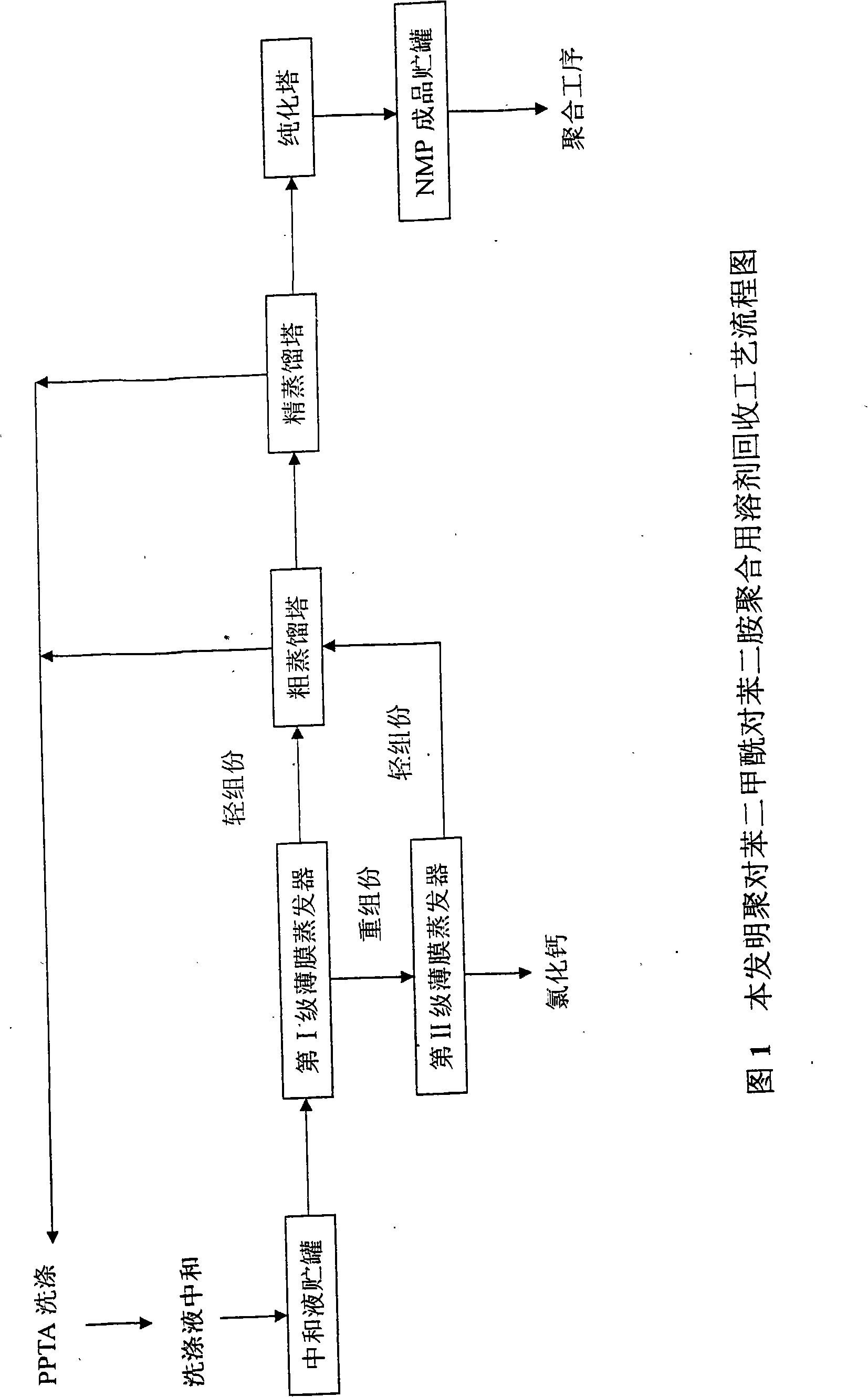

A technology of poly-p-phenylene terephthalamide and a new method, which is applied in the field of polymer material synthesis, can solve the problems of easy decomposition, lower recovery rate of NMP, and low recovery rate, and achieve a high degree of continuity and lower energy consumption. low consumption and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Contains 18% NMP, 3% CaCl 2 The neutralized washing liquid enters the first-stage thin-film evaporator from the storage tank at a flow rate of 50kg / hr, and its absolute pressure is controlled to be 1.0-1.5KPa, and the temperature is 100-120°C. Most of the NMP and water are vaporized and directly It enters the middle part of the crude distillation tower, and its heavy components enter the second-stage thin film evaporator. The absolute pressure inside the tower is 1.0-2.0Pa, and the temperature is 70-130°C. After removing most of the water in the solvent, enter the rectification tower to remove a small amount of water in the NMP, improve the purity of NMP, and control the absolute pressure inside the tower to 1.0~1.5Pa, the temperature is 70~130℃, and then through the purification tower to further reduce the trace moisture content in NMP, it enters the final NMP receiving tank, and the flow rate of receiving NMP is 8.7kg / hr, that is, the recovery rate of NMP reaches 96....

Embodiment 2

[0020] Contains 18% NMP, 3% CaCl 2 The neutralized washing liquid enters the first-stage thin-film evaporator from the storage tank at a flow rate of 40kg / hr, and its absolute pressure is controlled to be 1.0-1.5KPa, and the temperature is 100-120°C. Most of the NMP and water are vaporized and directly It enters the middle part of the crude distillation tower, and its heavy components enter the second-stage thin film evaporator. The absolute pressure inside the tower is 1.0-2.0Pa, and the temperature is 70-130°C. After removing most of the water in the solvent, enter the rectification tower to remove a small amount of water in the NMP, improve the purity of NMP, and control the absolute pressure inside the tower to 1.0~1.5Pa, the temperature is 70~130℃, and after further reducing the trace moisture content in NMP through the purification tower, it enters the final NMP receiving tank, and the flow rate of receiving NMP is 6.99kg / hr, that is, the recovery rate of NMP reaches 97...

Embodiment 3

[0022] Contains 18% NMP, 3% CaCl 2 The neutralized washing liquid enters the first-stage thin-film evaporator from the storage tank at a flow rate of 55kg / hr, and its absolute pressure is controlled to be 1.0-1.5KPa, and the temperature is 100-120°C. Most of the NMP and water are vaporized and directly It enters the middle part of the crude distillation tower, and its heavy components enter the second-stage thin film evaporator. The absolute pressure inside the tower is 1.0-2.0Pa, and the temperature is 70-130°C. After removing most of the water in the solvent, enter the rectification tower to remove a small amount of water in NMP, improve the purity of NMP, and control the absolute pressure inside the tower to 1.0~1.5Pa, the temperature is 70~130℃, after further reducing the trace moisture content in NMP through the purification tower, it enters the final NMP receiving tank, and the flow rate of receiving NMP is 9.53kg / hr, that is, the recovery rate of NMP reaches 96.3%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com