Dimensionally-stable polyimide film and preparation method thereof

A polyimide film and dimensionally stable technology, applied in the field of dimensionally stable polyimide film and its preparation, can solve problems such as unsatisfactory dimensional stability, achieve low thermal shrinkage, high elastic modulus and stretch The effect of strength, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

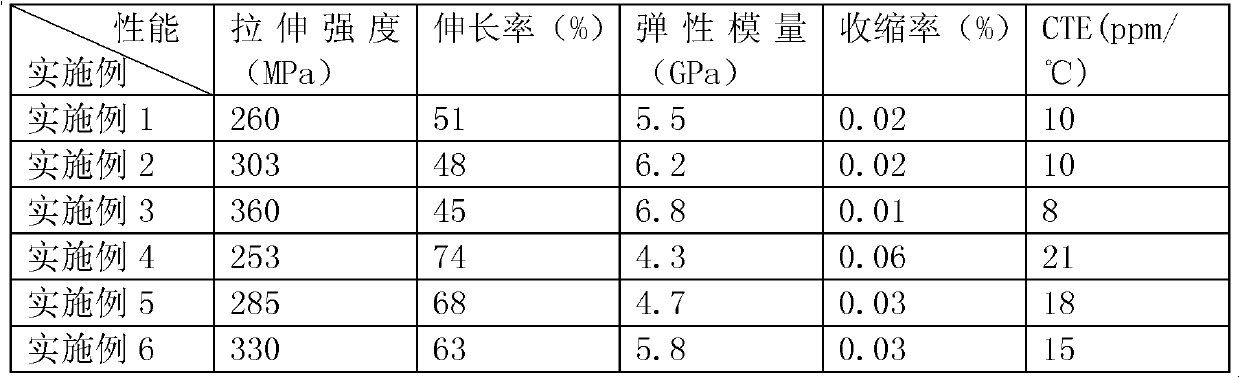

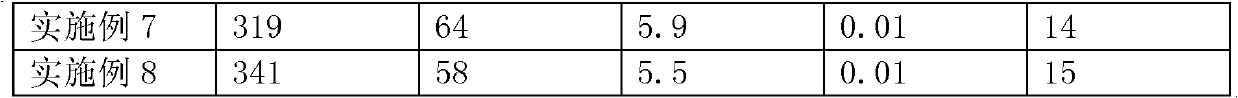

Examples

Embodiment 1

[0032] 1) Preparation of component A: Add 22.42g (0.1mol) of 2-(4-aminophenyl)-5-aminobenzimidazole into 215g of N,N-dimethylacetamide solvent at 25°C, After stirring for 10min, PMDA was added, and the ratio of the amount of 2-(4-aminophenyl)-5-aminobenzimidazole and PMDA added was 1:1, and then continued to stir for 3h, and the obtained polyamic acid resin solution was It is component A, and the measured viscosity of component A is 49,000 centipoise (25°C);

[0033] 2) Preparation of component B: at 25°C, add 21.63g (0.2mol) of PDA to 325g of N,N-dimethylacetamide solvent, stir for 20min, then add PMDA, the content of the added PDA and PMDA The ratio of the quantities is 1:1, and then the stirring is continued for 4 hours, and the obtained polyamic acid resin solution is the B component, and the measured viscosity of the B component is 55,000 centipoise (25°C);

[0034] 3) Under the condition of 25°C, mix component A and component B according to the ratio of 40% and 60% by w...

Embodiment 2

[0037] 1) Preparation of A component: same as Example 1;

[0038] 2) Preparation of B component: same as Example 1;

[0039] 3) Under the condition of 25°C, mix component A and component B according to the ratio of 60% and 40% by weight respectively, and mechanically stir for 8 hours to obtain a resin that is fully mixed and uniform between the molecules of each component;

[0040] 4) Vacuum defoaming and filtering the uniformly mixed resin, followed by salivation, stretching and thermal imidization according to the conventional process to obtain a dimensionally stable polyimide film.

Embodiment 3

[0042] 1) Preparation of component A: Add 22.42g (0.1mol) of 2-(4-aminophenyl)-5-aminobenzimidazole into 250g of N,N-dimethylacetamide solvent at 25°C, After stirring for 10 min, BPDA was added, and the ratio of the amount of 2-(4-aminophenyl)-5-aminobenzimidazole to BPDA was 0.99:1, and the stirring was continued for 5 h, and the obtained polyamic acid resin solution was It is component A, and the measured viscosity of component A is 52,000 centipoise (25°C);

[0043] 2) Preparation of B component: same as Example 1;

[0044] 3) Under the condition of 25°C, mix component A and component B according to the ratio of 80% and 20% by weight respectively, and mechanically stir for 4 hours to obtain a resin that is fully mixed and uniform between the molecules of each component;

[0045] 4) Vacuum defoaming and filtering the uniformly mixed resin, followed by salivation, stretching and thermal imidization according to the conventional process to obtain a dimensionally stable polyim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com