High-stability lithium ion battery diaphragm, preparation method thereof and lithium ion battery

A lithium-ion battery, high-stability technology, used in secondary batteries, battery pack components, circuits, etc., can solve problems such as affecting battery life, low melting point, and battery combustion and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

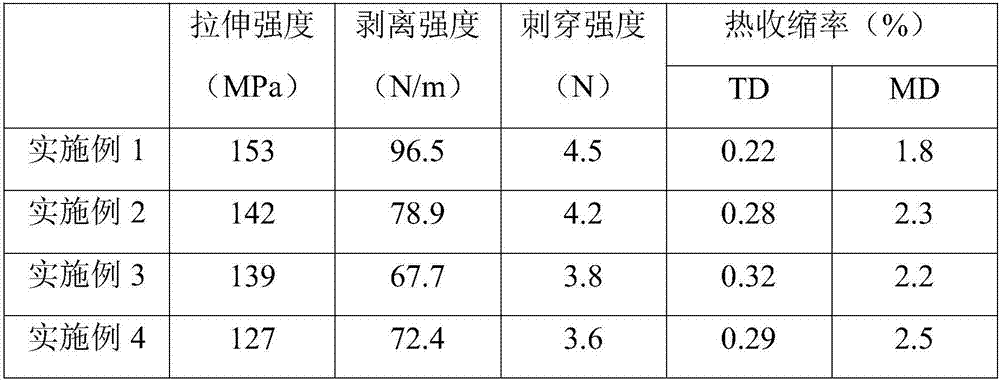

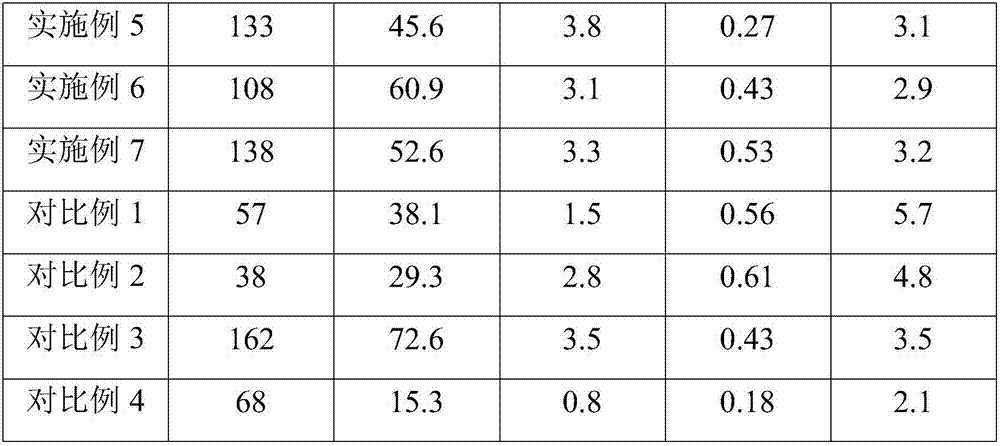

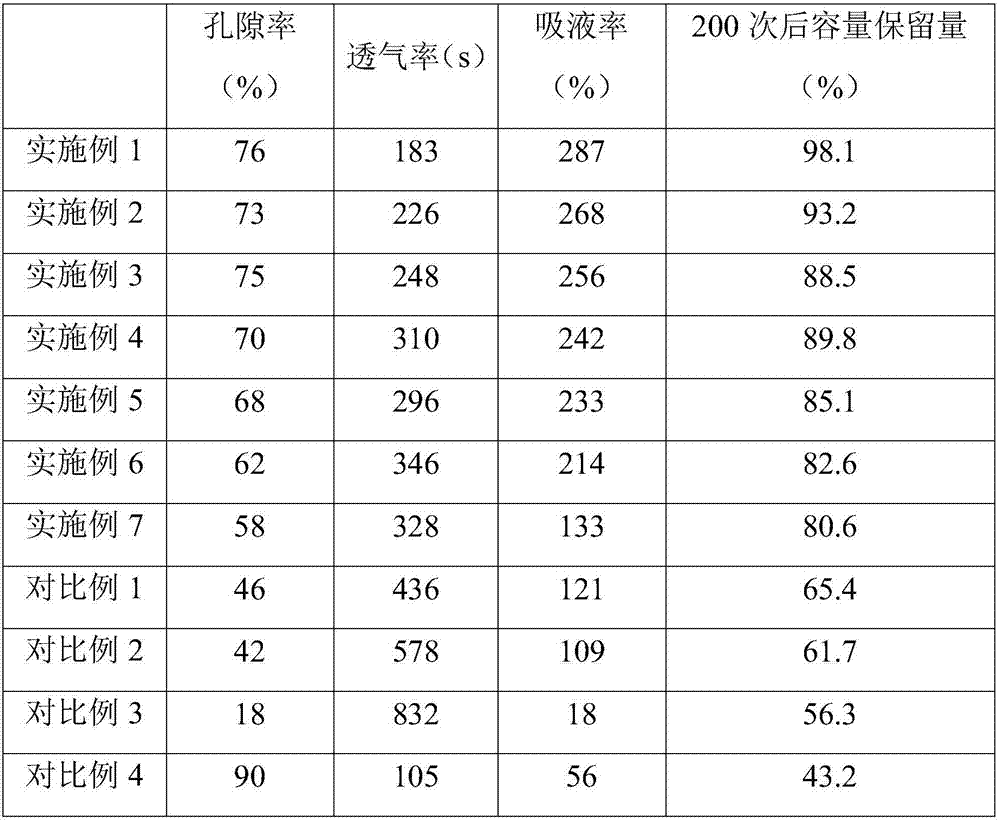

Examples

preparation example Construction

[0033] A method for preparing a high-stability lithium ion battery diaphragm includes the following steps:

[0034] (1) Ultrasonic dispersion of ceramic particles A and ceramic particles B in the dispersant uniformly, and then adding fibers and binders to ultrasonic dispersion to obtain ceramic slurry;

[0035] (2) Coating the ceramic slurry on the surface of the polymer matrix and then drying to obtain diaphragm A;

[0036] (3) Soak the separator A in an alkaline solution for 3-24 hours to obtain a lithium ion battery separator.

[0037] According to the present invention, the preparation method of the high-stability lithium ion battery separator further includes pretreatment of the fiber, and the pretreatment step includes soaking the fiber in a non-acidic solution for 2-24 hours, washing, sonicating, and filtering to obtain For the swelling fiber, it is further preferred that the diameter of the fiber is 5-20 nm and the length is 20-200 nm.

[0038] According to the present inventio...

Embodiment 1

[0046] A lithium ion battery is composed of a positive electrode, a negative electrode and a separator. The preparation method is as follows:

[0047] (1) Preparation of positive electrode

[0048] 100 parts by weight of LiNi 0.33 Co 0.33 Mn 0.34 O 2 , 4 parts by weight of polyvinylidene fluoride (PVDF) and 4 parts by weight of acetylene black are added to 50 parts by weight of N-methylpyrrolidone (NMP), and then stirred in a vacuum mixer to form a uniform positive electrode slurry; It is evenly coated on an aluminum foil with a width of 400mm and a thickness of 20μm, then dried at 120°C, rolled under a pressure of 1.6MPa, and then slit on a slitter to obtain a positive electrode with a size of 385mm×42mm×135μm.

[0049] (2) Preparation of negative electrode

[0050] Add 100 parts by weight of negative active material natural graphite, 4 parts by weight of polytetrafluoroethylene (PTFE), and 4 parts by weight of carbon black to 45 parts by weight of dimethyl sulfoxide (DMSO), and then...

Embodiment 2

[0059] A lithium ion battery is composed of a positive electrode, a negative electrode and a separator. The preparation method is as follows:

[0060] (1) The preparation method of the positive electrode is the same as in Example 1;

[0061] (2) The preparation method of the negative electrode is the same as in Example 1;

[0062] (3) Preparation of diaphragm:

[0063] Soak 2.2 parts by weight of ramie fibers in 1M potassium hydroxide (40°C) solution for 2h, then filter to remove the filtrate, wash the filter residue with water to neutrality, then ultrasonically disperse for 30min, filter to obtain swollen cellulose (diameter 10nm, length 200nm);

[0064] 17.6 parts by weight of zinc oxide (average particle size of 150nm), 24.3 parts by weight of zinc oxide (average particle size of 30nm) were uniformly dispersed in 44 parts by weight of polyvinylpyrrolidone ultrasonically, and then swollen fibers and 0.2 parts by weight of polyimide were added. Silk (average diameter of 100nm), 1 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com