Covalence organic frame/graphene composite materials, preparing method and application

A technology of covalent organic framework and composite material, which is applied in the field of supercapacitor electrode materials, can solve the problem that the performance needs to be further developed, and achieve the effect of good cycle stability and high capacitance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described with examples below, and these examples only illustrate the method of the present invention, without any limitation on the scope of application of the present invention.

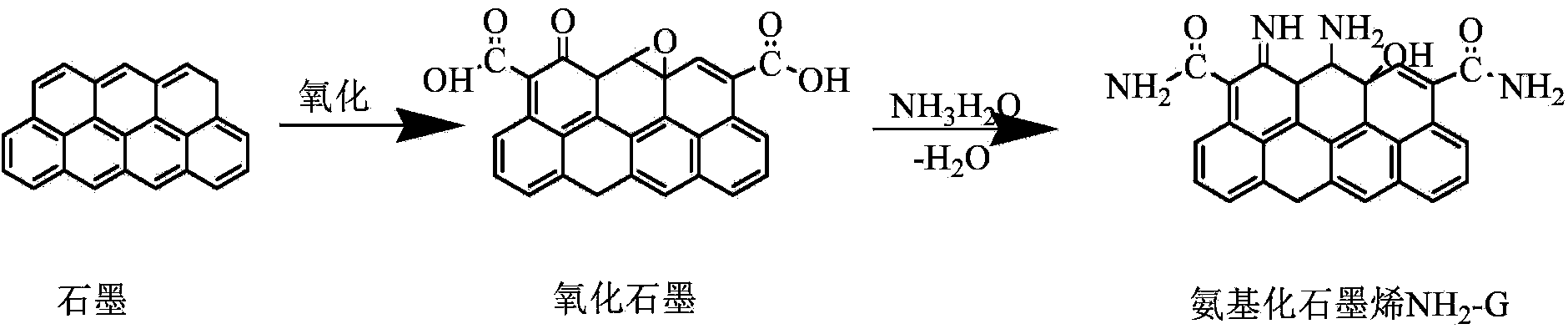

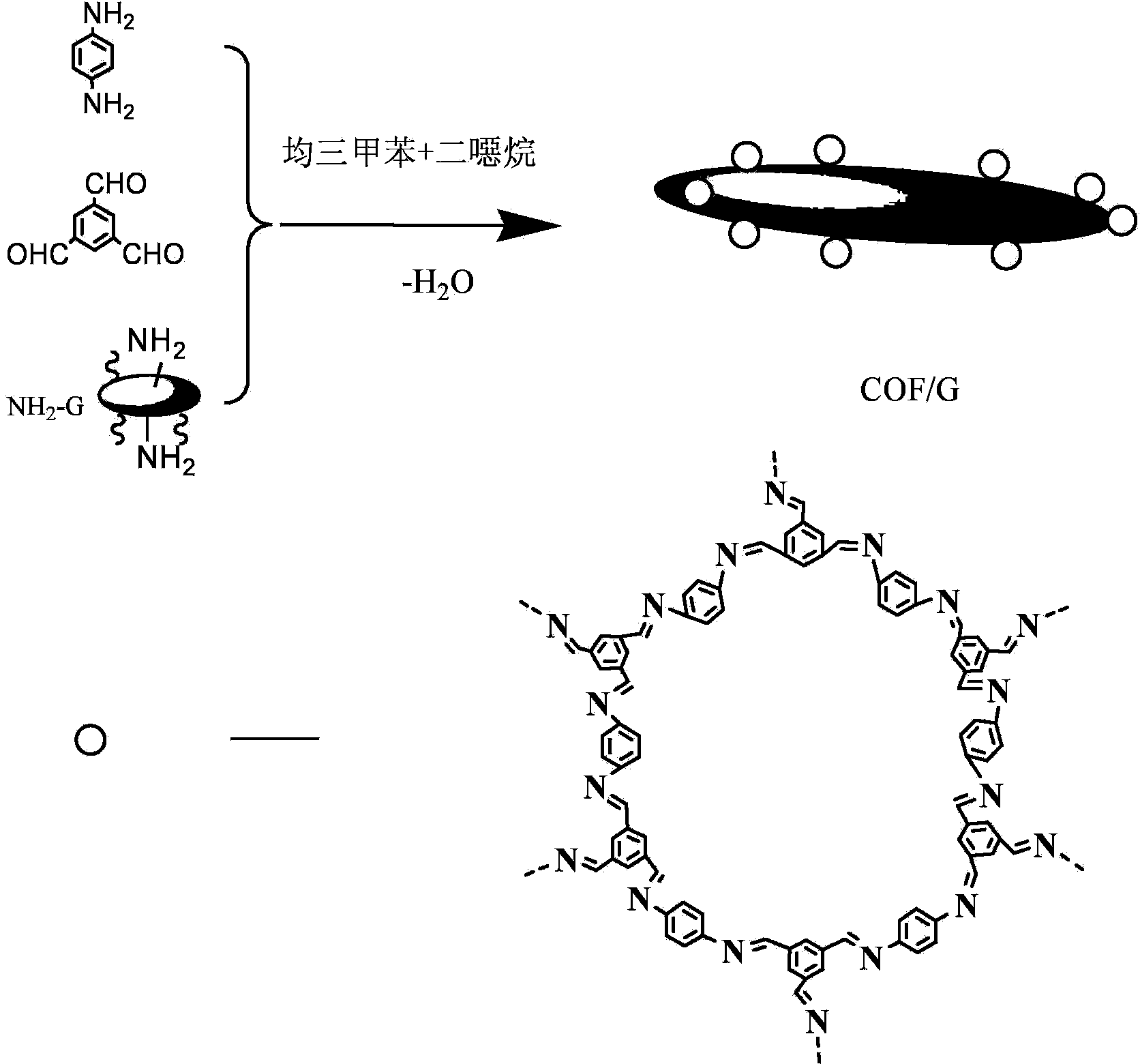

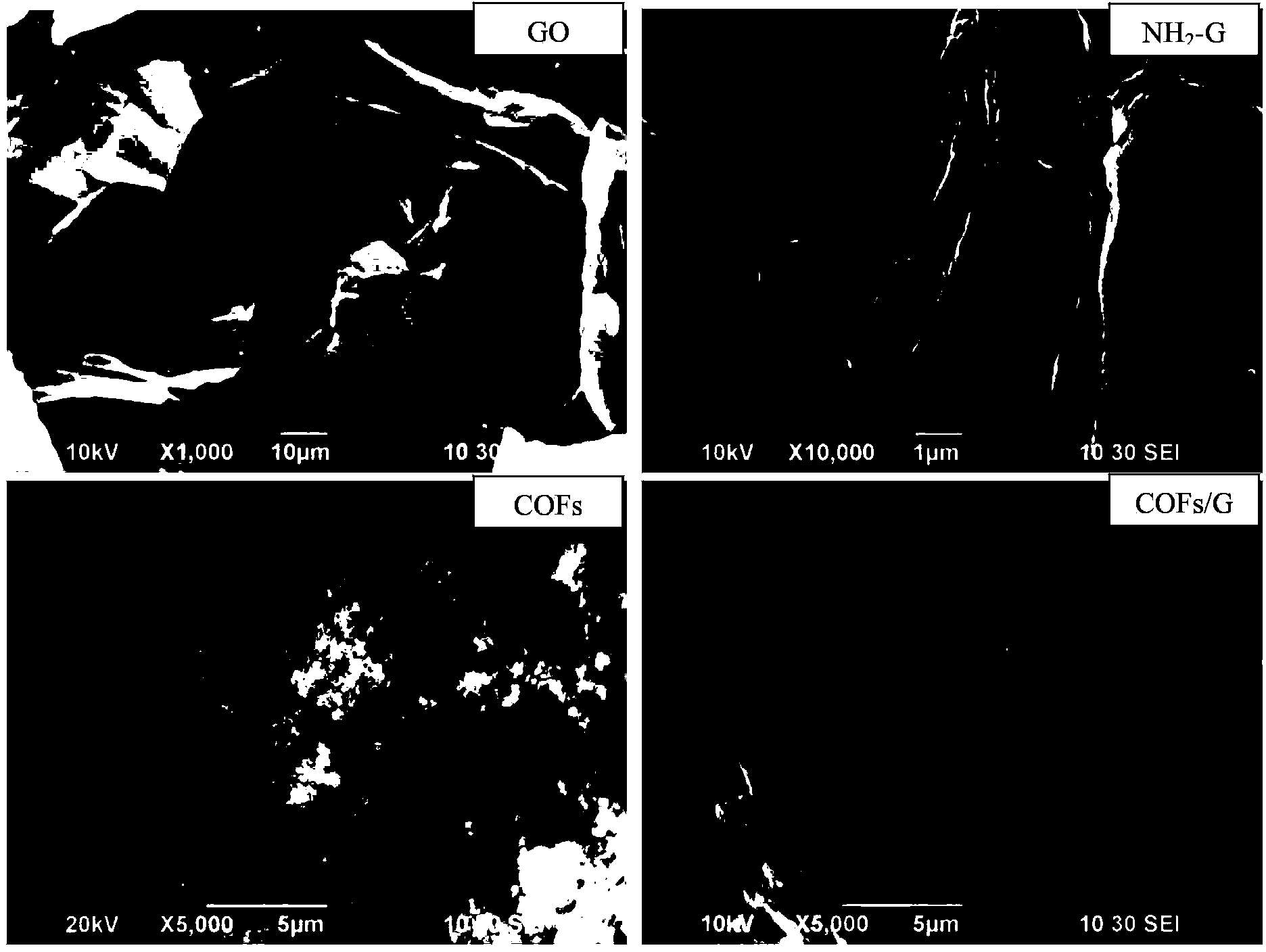

[0028] The present invention is raw material with flake graphite, has synthesized graphite oxide by the improved Hummers method, and further reacts with ammoniacal liquor to prepare aminated graphene (as figure 1 ), aminated graphene reacts with trimesaldehyde and p-phenylenediamine under the catalysis of acetic acid to synthesize a covalent organic framework / graphene composite (such as figure 2 ), and mix it with the conductive agent Ketjen black and the binder PTFE solution and coat it on the nickel foam, press it and dry it and use it as the electrode material of the supercapacitor.

[0029] The synthesis steps of the covalent organic framework / graphene composite material involved in the present inven...

Embodiment 1

[0034] Example 1: Synthesis of covalent organic framework / graphene composite COFs / G-0.5.

[0035] Such as figure 2 Add 24mg of aminated graphene, 6ml of 1,4-dioxane and 1,3,5-trimethylbenzene 1:1 mixed solution, 48mg of trimesaldehyde and 48mg of p-phenylenediamine in the reactor, magnetic Stir for 40min. Add 0.6 ml of 3 mol / L acetic acid to the mixture, stir it magnetically for 20 min, place it in a high-pressure reactor, and react at 120° C. for 48 h. After the reaction was completed, it was centrifuged and washed three times with N,N-dimethylformamide (10 ml each time), and then washed three times with tetrahydrofuran (10 ml each time). After washing, place it in a vacuum oven at 80°C and dry it in vacuum for 12 hours. After drying and grinding, the covalent organic framework / graphene composite material COFs / G-0.5 was obtained.

Embodiment 2

[0036] Example 2: Synthesis of covalent organic framework / graphene composite COFs / G-1.

[0037] Such as figure 2 Add 48mg of aminated graphene, 6ml of 1,4-dioxane and 1,3,5-trimethylbenzene 1:1 mixed solution, 48mg of trimesaldehyde and 48mg of p-phenylenediamine in the reactor, magnetic Stir for 40min. Add 0.6 ml of 3 mol / L acetic acid to the mixture, stir it magnetically for 20 min, place it in a high-pressure reactor, and react at 120° C. for 48 h. After the reaction was completed, it was centrifuged and washed three times with N,N-dimethylformamide (10 ml each time), and then washed three times with tetrahydrofuran (10 ml each time). After washing, place it in a vacuum oven at 80°C and dry it in vacuum for 12 hours. After drying and grinding, the covalent organic framework / graphene composite material COFs / G-1 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com