Compound reverse osmosis membrane with interpenetrating network desalting layer and preparation method of membrane

A technology of reverse osmosis membrane and interpenetrating network, applied in the field of nano-modified membrane materials, can solve the problem that the technology is difficult to meet the requirements, and achieve the effect of high anti-pollution ability and emphasis on control ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

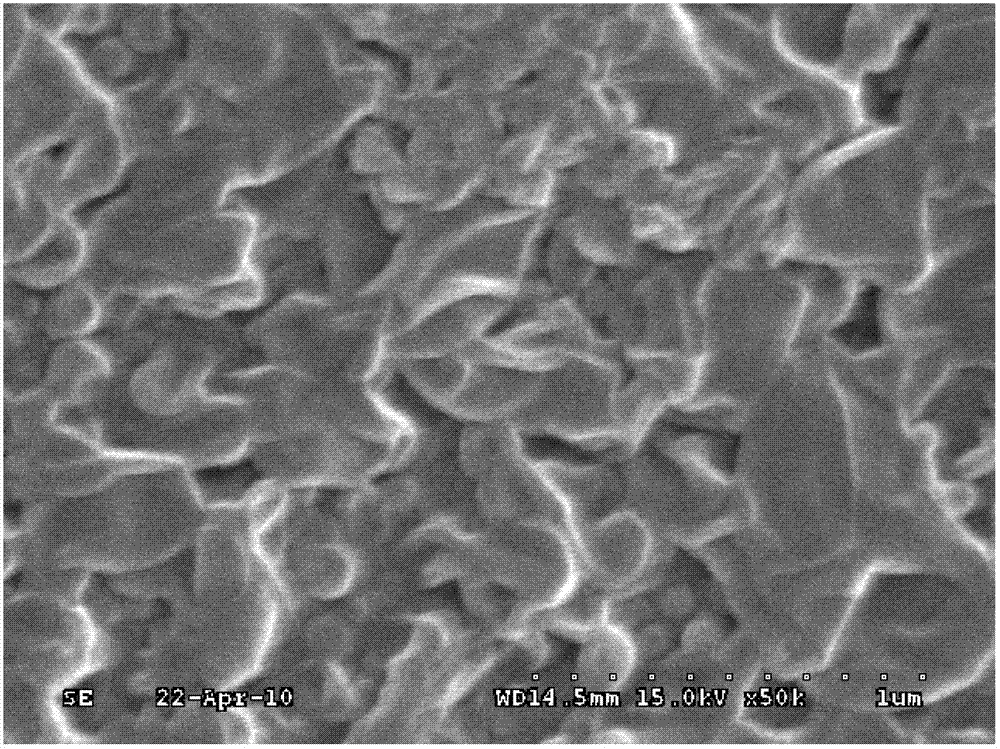

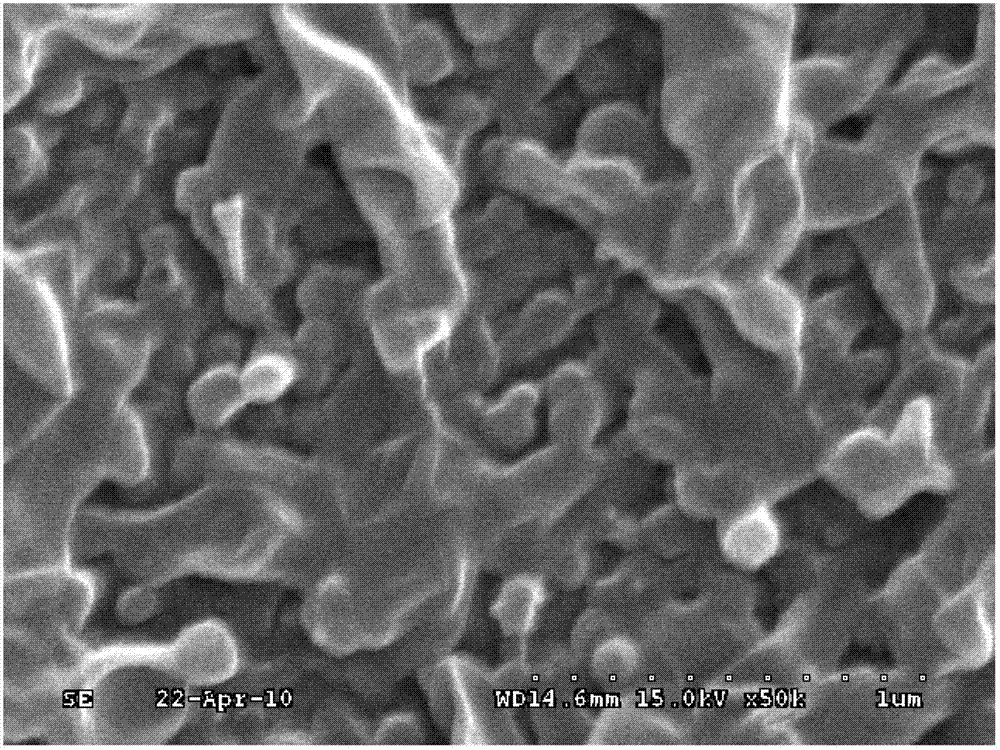

Image

Examples

Embodiment 1

[0039] (1) Pre-dispersion of polymer nanogel particles: Take 80g of polyvinyl alcohol nanogel (particle size 150nm, swelling degree 71.4wt%) in a fully swollen state and disperse it in 1920g of deionized water. After ultrasonic dispersion treatment for 60min, the nanogel dispersion was prepared;

[0040] (2) Preparation of solution A: Dissolve 35g of m-phenylenediamine in 965g of the polyvinyl alcohol nanogel dispersion described in step (1) to prepare a solution with a concentration of m-phenylenediamine of 3.5wt%, stir well and dissolve completely , add 5g N, N-dimethylformamide (DMF) and 0.5g appropriate amount of sodium hydroxide in turn, stir and dissolve the mixed solution to obtain A solution;

[0041] (3) Prepare B solution: Dissolve 2.1g of trimesoyl chloride in 997.9g of cyclohexane to prepare a solution with a concentration of 0.21wt%, and obtain B solution after complete dissolution;

[0042] (4) Soak the polysulfone porous support layer in solution A for 30s, tak...

Embodiment 2

[0046] (1) Pre-dispersion of polymer nanogel particles: Take 80g of polyvinyl alcohol nanogel in a fully swollen state (particle size ~ 550nm, swelling degree 80wt%) and disperse it in 1920g of deionized water. After ultrasonic dispersion treatment for 60min, the nanogel dispersion was prepared;

[0047] (2) Preparation of solution A: Dissolve 35g of m-phenylenediamine in 965g of the polyvinyl alcohol nanogel dispersion described in step (1) to prepare a solution with a concentration of m-phenylenediamine of 3.5wt%, stir well and dissolve completely , add 5g N, N-dimethylformamide (DMF) and 0.5g sodium hydroxide in sequence, stir and dissolve the mixed solution to obtain A solution;

[0048] (3) Prepare B solution: Dissolve 2.1g of trimesoyl chloride in 997.9g of cyclohexane to prepare a solution with a concentration of 0.21wt%, and obtain B solution after complete dissolution;

[0049] (4) Soak the polysulfone porous support layer in solution A for 1 second, take it out and ...

Embodiment 3

[0053] (1) Pre-dispersion of polymer nanogel particles: take 80g of polyvinyl alcohol nanogel (particle size ~ 200nm, swelling degree 86wt%) in a fully swollen state and disperse them in 1920g of deionized water, stir them evenly and use ultrasonic waves After ultrasonic dispersion treatment for 60min, the nanogel dispersion was prepared;

[0054] (2) Preparation of solution A: Dissolve 35g of m-phenylenediamine in 965g of the polyvinyl alcohol nanogel dispersion described in step (1) to prepare a solution with a concentration of m-phenylenediamine of 3.5wt%, stir well and dissolve completely , add 5g N, N-dimethylformamide (DMF) and 0.5g sodium hydroxide in sequence, stir and dissolve the mixed solution to obtain A solution;

[0055] (3) Prepare B solution: Dissolve 2.1g of trimesoyl chloride in 997.9g of cyclohexane to prepare a solution with a concentration of 0.21wt%, and obtain B solution after complete dissolution;

[0056] (4) Soak the polysulfone porous support layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com