Method for preparing p-phenylenediamine rubber aging inhibitor

A technology of rubber anti-aging agent and p-phenylenediamine, which is applied in the field of rubber anti-aging agent preparation, can solve the problems of low quality of 4020 products, reduce the amount of MIBK, and more methyl isobutyl carbinol, and achieve large industrial application value , Reduce the difficulty of reaction, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

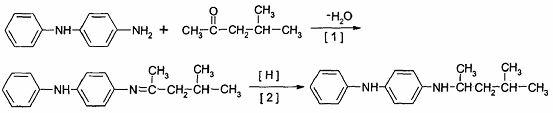

Problems solved by technology

Method used

Image

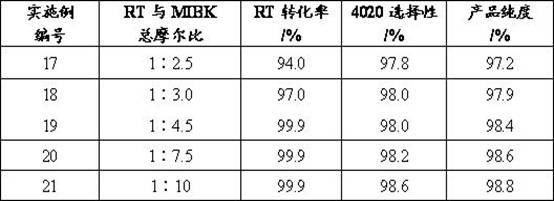

Examples

Embodiment 1

[0034] (a) Condensation reaction

[0035] Into a 1L autoclave equipped with a condenser and an oil-water separator, put 150g (0.8mol) RT times and 120g (1.2mol) MIBK, when the temperature of the material in the reactor is raised to 130°C, the pressure is about 0.5MPa, and the heat preservation is started 4h. The temperature is controlled not to exceed 150°C. The oil-water separator brings out MIBK steam and water vapor. After condensation, MIBK and water enter the receiving tank for oil-water separation. Water is in the lower layer, MIBK is in the upper layer, and MIBK returns to high pressure from the overflow port on the upper part of the receiving tank. kettle. After the reaction was completed, the temperature was lowered and the pressure was released, and 13.9 g of water was separated from the receiving tank, and the remaining MIBK was returned to the autoclave, and the autoclave was poured out and weighed. The conversion rate of RT times was 97% according to sampling ana...

Embodiment 2~9

[0042] The experiment was carried out as in Example 1, except that the pressure, temperature and reaction time of the hydrogenation reaction step were different. The results of the conversion rate, selectivity and product purity of the hydrogenation reaction are summarized in Table 1.

[0043] Table 1 Experimental results using different hydrogenation process conditions

[0044]

[0045] The results show that the present invention has a good reaction effect at low temperature (about 100°C) and low pressure (1.0-4.0 MPa), and the product purity can reach more than 98%.

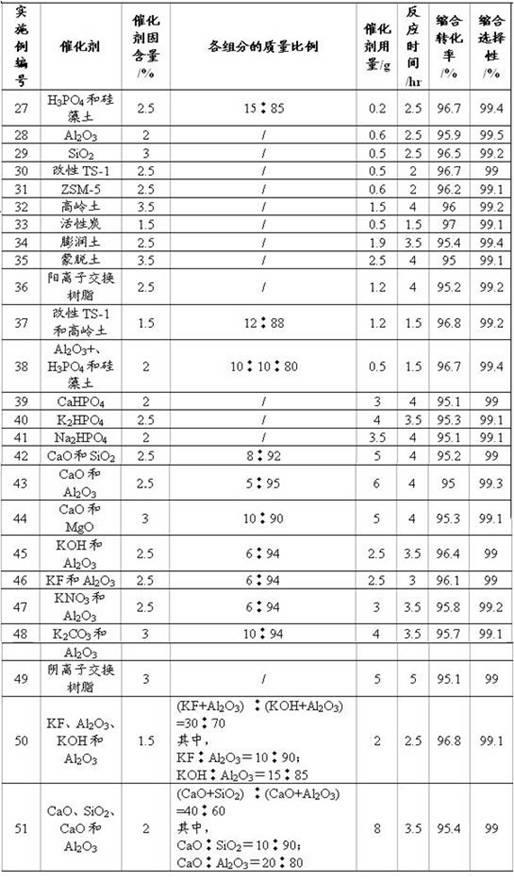

Embodiment 10~16

[0047] The experiment was carried out as in Example 1, except that the catalysts used in the hydrogenation reaction were Raney Ni, amorphous Ni, diatomaceous earth loaded Ni, 0.8%Pd / C, 5%Pd / C, 2%Pt / C, 5%Pt / C. The hydrogenation reaction conditions are the same as in Example 1. The experimental results are summarized in Table 2.

[0048] Table 2 Experimental results using different hydrogenation catalysts

[0049]

[0050] The results show that the conversion rate of the noble metal catalyst is high, while the conversion rate of the Ni catalyst is slightly lower, but the purity of 4020 is relatively high, and the cost of the Ni catalyst is much lower than that of the noble metal catalyst, which can effectively reduce the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com