Method for preparing environment-friendly polyurethane adhesive for plastic track

A technology of polyurethane adhesives and plastic runways, which is applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive additives, etc., and can solve problems such as environmental pollution, adhesive performance differences, and risks for builders and users , to reduce cost, increase tensile strength and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

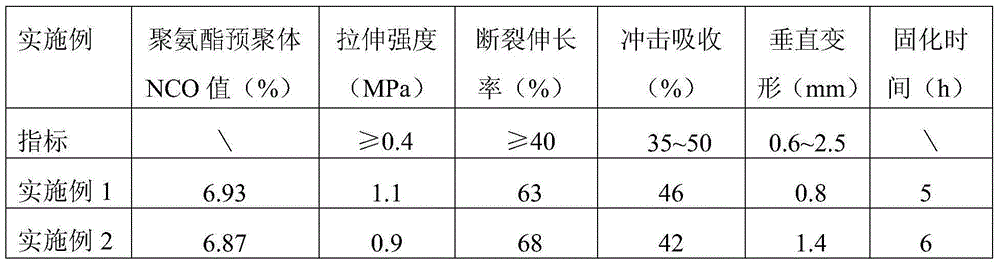

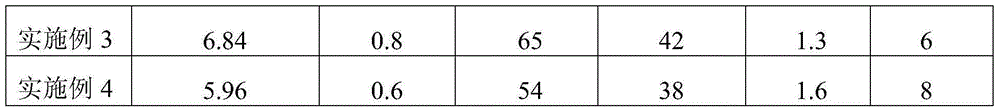

Examples

Embodiment 1

[0021] Add 150.39g of propylene oxide polyether triol (ZS-1618A, 5000), 50.37g of polytetrahydrofuran ether glycol (PTMG1500), and 4.02g of fumed silica into a 500ml three-necked flask and stir rapidly at -0.1MPa, Carry out dehydration treatment at 100°C for 2 hours, when the temperature drops to about 45°C, add 96.57g of diphenylmethane diisocyanate (MDI-50), react naturally for 30 minutes, then slowly raise the temperature to 80°C and continue the reaction for 1 hour Finally, add 0.20 g of an organotin catalyst to continue the reaction for 1 h to obtain a polyurethane prepolymer with terminal isocyanate groups. The obtained prepolymer was cooled to 40° C., and 25.03 g of 52° chlorinated paraffin and 25.03 g of dibutyl phthalate (DBP) were added respectively, and then ultraviolet absorber UV-329 (0.9 g), UV-622 (0.9g) and antioxidant 1010 (0.6g), then stirred at high speed for 30 minutes to make them evenly mixed. Finally, vacuumize and defoam the adhesive prepared above for...

Embodiment 2

[0024]Add 153.68g of polyether triol (ZS-1618A, 5000), 51.76g of polypropylene oxide diol (PPG3000), and 2.1g of fumed silica into a 500ml three-necked flask and stir rapidly, at -0.1MPa, 110°C Under the conditions of dehydration for 3 hours, when the temperature drops to about 55°C, add 95.43g of diphenylmethane diisocyanate (MDI-50), react naturally for 40 minutes, then slowly raise the temperature to 85°C and continue the reaction for 1 hour. Add 0.16 g of organotin catalyst and continue to react for 30 minutes to prepare isocyanate-terminated polyurethane prepolymer. The obtained prepolymer was cooled to 45°C, and 25.91g of 52°C chlorinated paraffin and 25.91g of dibutyl phthalate (DBP) were added respectively, and then the ultraviolet absorber UV-329 (1.2g), UV-622 (1.2g) and antioxidant 1010 (0.8g), then stirred at high speed for 60 minutes to make them evenly mixed. Finally, vacuumize and defoam the adhesive prepared above for 23 minutes, and pass nitrogen gas into it,...

Embodiment 3

[0027] Add 151.88g of polyether triol (ZS-1618A, 5000), 78.71g of polypropylene oxide diol (PPG3000), and 4.76g of fumed silica into a 500ml three-necked flask and stir rapidly at -0.1MPa, 105°C Dehydration treatment was carried out for 2 hours under certain conditions, and when the temperature dropped to about 50°C, 99.24g of diphenylmethane diisocyanate (MDI-50) was added, and reacted naturally for 30 minutes, and then slowly raised to 80°C to continue the reaction for 1 hour. Add 0.18 g of organotin catalyst and continue to react for 1 h to obtain isocyanate-terminated polyurethane prepolymer. The obtained prepolymer was cooled to 45°C, and 27.24g of 52°C chlorinated paraffin and 27.24g of dibutyl phthalate (DBP) were added respectively, and then the ultraviolet light absorber UV-329 (1.2g), UV-622 (1.2g) and antioxidant 1010 (0.8g), then stirred at high speed for 30 minutes to make them evenly mixed. Finally, vacuumize and defoam the adhesive prepared above for 18 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com