Production method for vacuum-rolling layered metal composite board

A layered metal, vacuum rolling technology, applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problems of non-fitting of the edges, time-consuming and energy-consuming, and the billet is prone to bulge, etc. Avoid the edge does not fit, is not easy to contaminate, and avoids the effect of bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

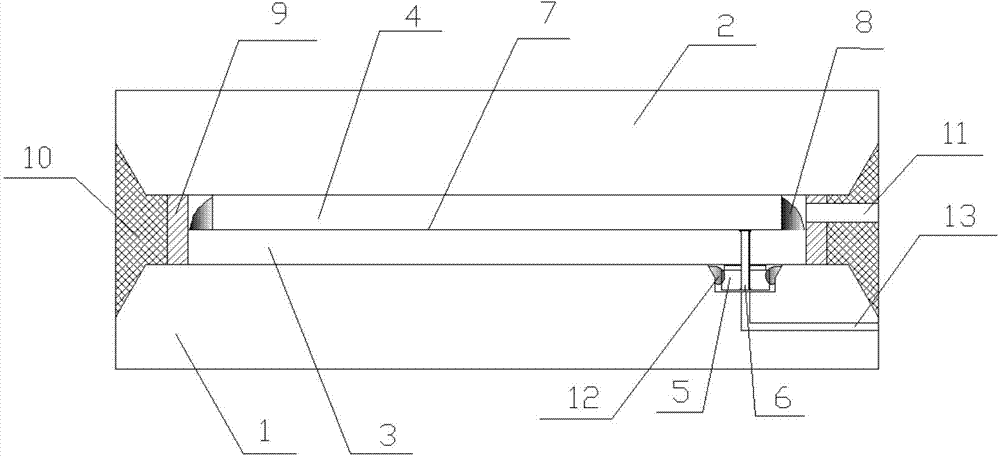

[0019] Rolling 1.2mm titanium (TA2) and 10mm steel (Q235B) clad plate billets, the size of two base plates is 100×1100×1600mm, the size of one TA2 plate is 12×1000×1500mm, and the size of one TA2 plate is 12×980×1480mm.

[0020] 1) Drill a blind hole with a depth of Φ30±1mm and a depth of 50±5mm at a corner of a substrate, 60~70mm away from the edge, and drill a through hole perpendicular to the center line of the blind hole in the width direction of the substrate. The diameter of the through hole is Φ10~20mm, the through hole is 25±5mm away from the surface to be compounded.

[0021] 2) Weld a TA2 (1.2~2) mm+Q235B (15~20) mm, Φ26±1mm transition joint on the blind hole, drill a Φ10~20mm through hole in the center of the transition joint, and weld a Φ10~ 20mm TA2 seamless pipe.

[0022] 3) Drill a Φ10~20mm through hole on the 12×1000×1500mm TA2 titanium plate at the corresponding position, pass through the seamless TA2 tube and place it on the substrate equilaterally, and weld...

Embodiment 2

[0028] Rolling 2mm stainless steel (304) and 8mm steel (Q235B) composite plate assembly, take two substrates with a size of 100×2100×2600mm, one 304 plate with a size of 25×2000×2500mm, and one 304 plate with a size of 25×1980×2480mm.

[0029] 1) Drill a blind hole with a depth of Φ30±1mm and a depth of 50±5mm at a corner of a substrate, 60~70mm away from the edge, and drill a through hole perpendicular to the center line of the blind hole in the width direction of the substrate. The diameter of the through hole is Φ10~20mm, the through hole is 25±5mm away from the surface to be compounded.

[0030] 2) Weld a transition joint made of Q235B, thickness 15~20mm, Φ26±1mm on the blind hole, drill a Φ10~20mm through hole in the center of the transition joint, and weld a Φ10~20mm seamless steel pipe or no Sew stainless steel pipes.

[0031] 3) At the corresponding position on the 25×1980×1500mm304 stainless steel plate, drill a Φ10~20mm through hole, pass through the seamless steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com