Concrete plastering surface emulsion paint coating technique

A technology for plastering and latex paint, which is applied in construction, building structure, covering/lining, etc., can solve the problems of reduced paint layer connection effect, insufficient brushing treatment, short service life, etc., and achieves good moisture-proof effect, The effect of improving the connection effect and increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

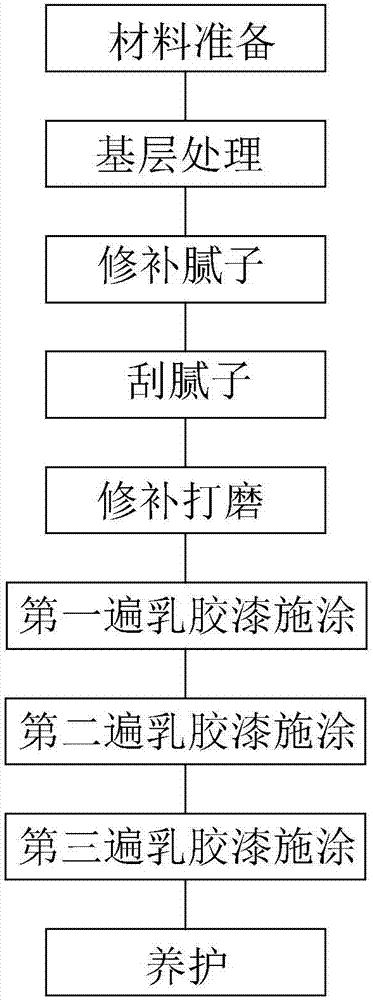

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] A kind of concrete plastering surface latex paint brushing technique, comprises the steps:

[0033] Step 1: Material preparation: prepare coatings, fillers, and pigments;

[0034] Paint: vinyl acetate latex paint, acrylic latex paint;

[0035] Filling materials: large white powder, gypsum powder, talcum powder, carboxymethyl cellulose, polyvinyl acetate emulsion, floor yellow, red soil, black tobacco, lithopone, etc.;

[0036] Pigments: organic or inorganic pigments of various colors with alkali resistance and light resistance.

[0037] Step 2: Base treatment: keep the wall dry, and the moisture content of the base should not exceed 10%;

[0038] The plastering work has been completed, and the wall pipes, openings, yin and yang corners, etc. should be treated in advance to ensure that the wall is dry, and all kinds of wall holes should be filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com