Modified wood composition and its manufacturing method and application

A technology of wood modification and composition, which is applied in the direction of impregnating wood, wood impregnation, wood processing equipment, etc., can solve the problems of reduced wood performance, poor wood impregnation effect, high viscosity of urea-formaldehyde resin, etc., to solve cracking deformation, physical Improvement of mechanical properties and environmental protection of the system process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] One, the preparation of wood modification composition

[0041] (1) Preparation of component A: Take 550kg of formaldehyde (37%) and add 30% sodium hydroxide to adjust the pH to 8.0-8.5, add 207kg of urea, heat up to 90°C for 30 minutes, and keep warm for 20 minutes; add citric acid to adjust the pH to 4.6 ~4.8, temperature 90℃, polycondensation reaction 50~60min (refer to 30℃ Tu-4 viscosity 14~20s), adjust pH 7.5~8.0, cool down and discharge.

[0042] (2) Preparation of component B: Take 100kg of formaldehyde (37%), add 23kg of water, add 25% ammonia water to adjust the pH to 8.0-8.5, add 148kg of urea, heat up to 90°C for 30 minutes, keep warm for 15 minutes, adjust the pH to 7.0 with 25% ammonia water. 5-8.0, cooling and discharging;

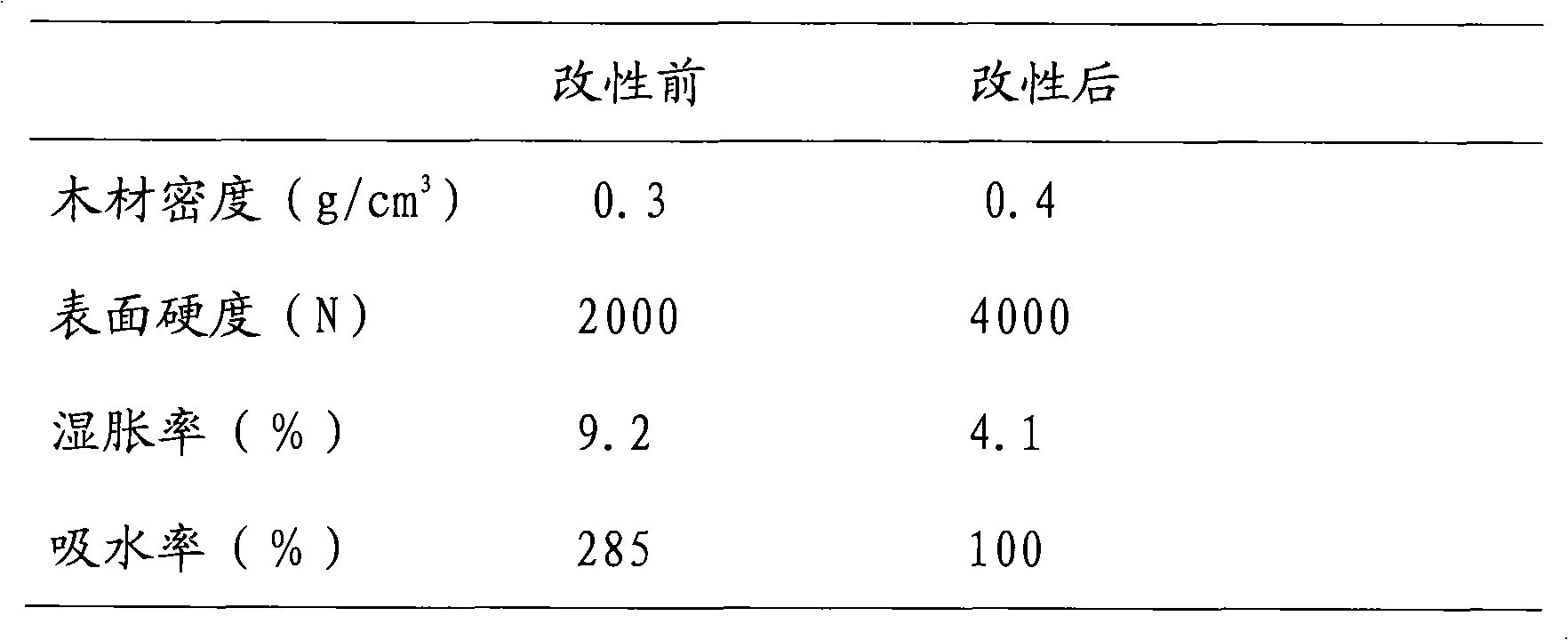

[0043] The modified composition of the present invention is obtained by mixing component A and component B according to a weight ratio of 1:1, and its properties are shown in Table 1.

[0044] Table 1 Performance of modified compositi...

Embodiment 2

[0053] One, the preparation of wood modification composition

[0054] (1) Preparation of component A: Take 500kg of glyoxal (40%) and add 25% ammonia water to adjust the pH to 8.5-9.0, add 207kg of urea, heat up to 85°C in 35 minutes, keep warm for 30 minutes; add oxalic acid to adjust the pH to 4.8- 5.0, temperature 85°C, polycondensation reaction 40min (refer to 30°C Tu-4 viscosity 14~20s), adjust pH 8.0~8.5, cool down and discharge.

[0055] (2) Preparation of component B: Take 200kg of glyoxal (40%), add 66.7kg of water, add 25% ammonia water to adjust the pH to 8.5-9.0, add 138kg of urea, heat up to 85°C for 35 minutes, keep warm for 35 minutes, 25% ammonia water Adjust the pH to 8.5-9.0, cool down and discharge. ;

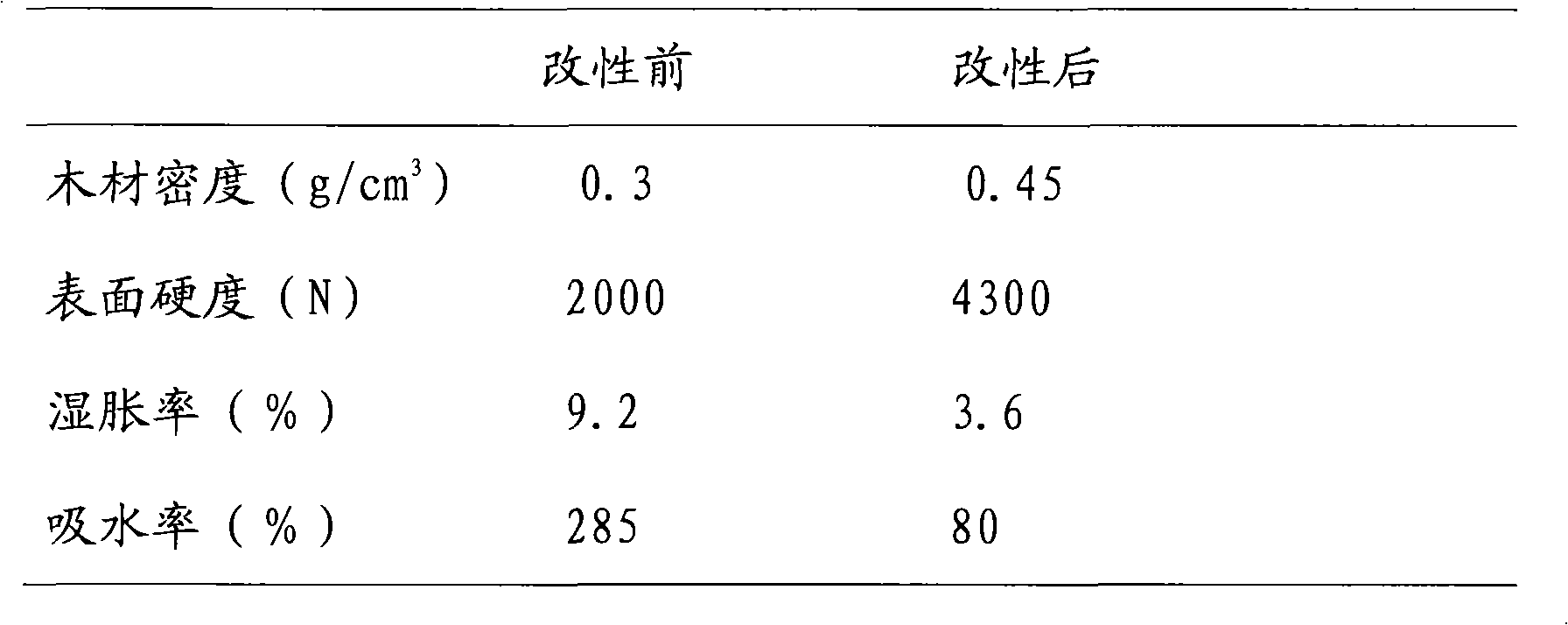

[0056] The modified composition of the present invention is obtained by mixing component A and component B according to a weight ratio of 1:1, and its properties are shown in Table 3.

[0057] Table 3 Performance of modified composition of the present inve...

Embodiment 3

[0066] One, the preparation of wood modification composition

[0067] (1) Preparation of component A: Take 580kg of propionaldehyde (100%) and add 25% ammonia water to adjust the pH to 8.5-9.0, add 487kg of triethylenetetramine, heat up to 85°C for 40 minutes, and keep warm for 30 minutes; add oxalic acid to adjust the pH to 3. 8~4.0, temperature 90℃, polycondensation reaction 50min (refer to 30℃ Tu-4 viscosity 14~20s), adjust pH 9.5~10.0, cool down and discharge.

[0068] (2) Preparation of component B: Take 200kg of formaldehyde (37%), add 50kg of water, add 30% sodium hydroxide to adjust the pH to 9.5-10.0, add 180kg of triethylenetetramine, heat up to 90°C in 45 minutes, and keep the temperature for 40 minutes. % ammonia water to adjust the pH to 9.5-10.0, cool down and discharge. ;

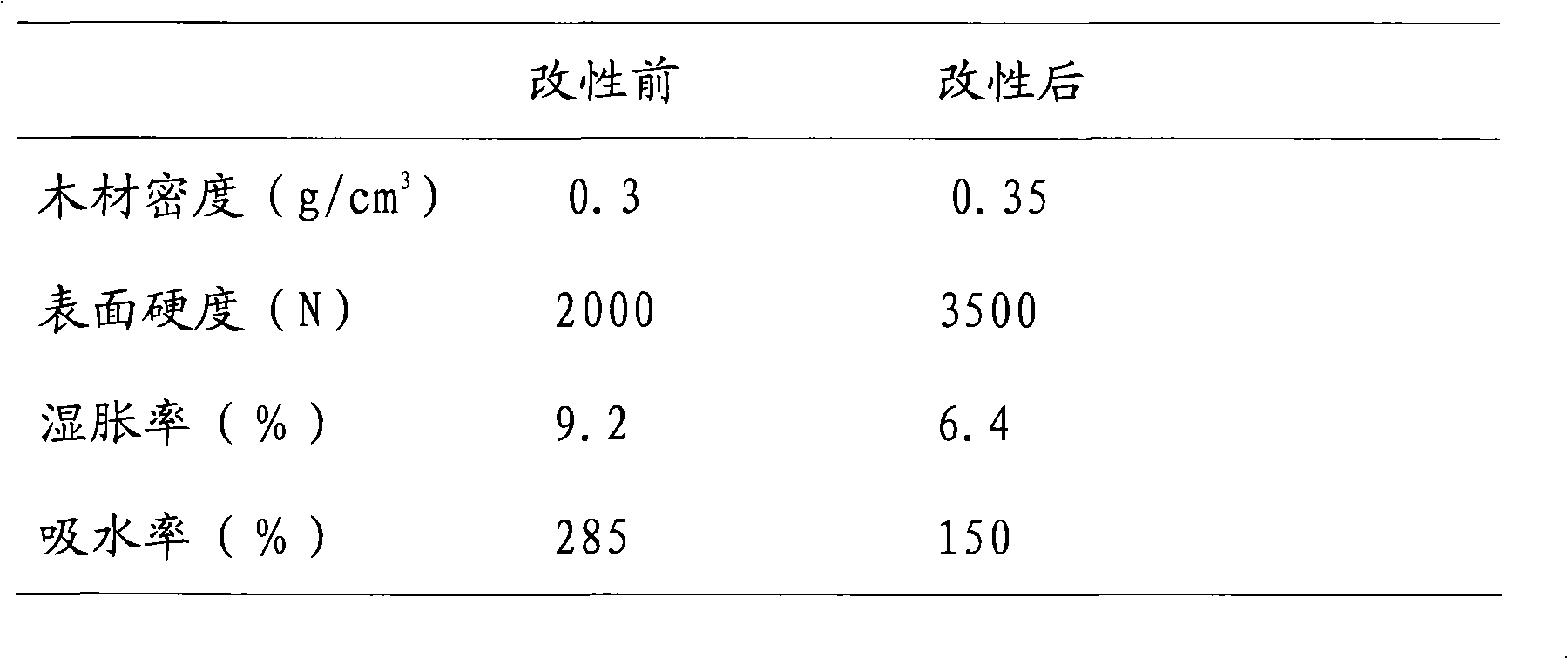

[0069] The modified composition of the present invention is obtained by mixing component A and component B according to a weight ratio of 1:1, and its properties are shown in Table 5.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com