Aqueous transparent super-hydrophobic paint and preparation method thereof

A super-hydrophobic coating, water-based technology, applied in coatings and other directions, can solve problems such as unfavorable transportation, environmental pollution, flammable human body, etc., and achieve the effect of reducing cost, good transparency and low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

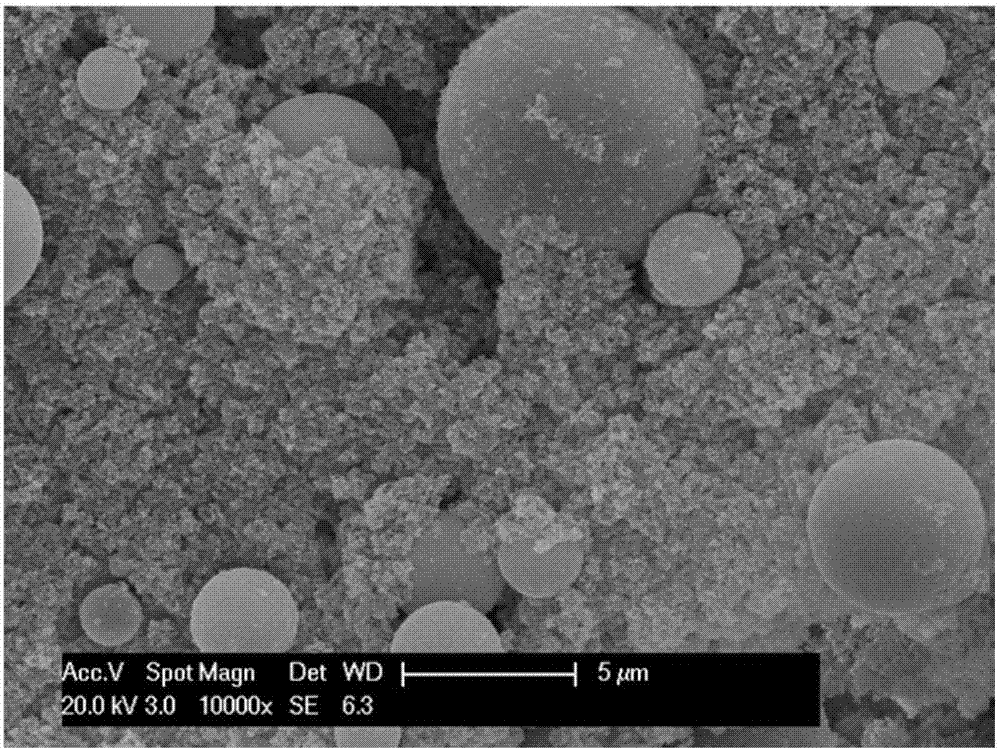

[0025] Add 80mL of deionized water into the reaction kettle equipped with a reflux device, add 4mL of ammonia water, stir evenly, add 1.2g of aqueous silica sol with a pH value of 2-4, and stir at 50-200rpm for 30 minutes. Increase the stirring speed to 500-2000rpm, and adjust the temperature of the water bath to 60°C, add 0.12g each of 2μm and 5μm silica powder, then stir at 50-200rpm for 30 minutes, and finally add 0.6mL tetraethyl orthosilicate, 0.6mL n-octyltriethoxysilane, after stirring for 24 hours, a water-based super-hydrophobic coating with a micro-nano composite structure was obtained (no silicone or silicon-modified resin was added). figure 1 A scanning electron microscope image of the coating.

Embodiment 2

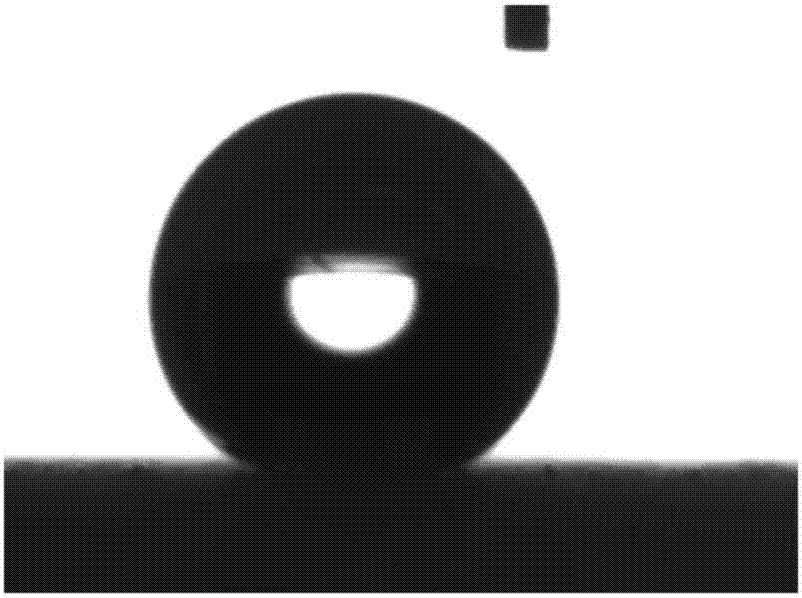

[0027] Add 80mL of deionized water into the reaction kettle equipped with a reflux device, add 4mL of ammonia water, stir evenly, add 1.2g of aqueous silica sol with a pH value of 2-4, and stir at 50-200rpm for 30 minutes. Increase the stirring speed to 500-2000rpm, and adjust the temperature of the water bath to 60°C, add 0.12g each of 0.5μm and 2μm silica powder, then stir at 50-200rpm for 30 minutes, and finally add 0.6mL tetraethyl orthosilicate, 0.6 mL of n-octyltriethoxysilane, stirred for 24 hours to obtain a water-based superhydrophobic coating with a micro-nano composite structure (without adding silicone or silicon-modified resin). figure 2 is the water contact angle image of the coating. Its water contact angle is 154° and its rolling angle is 2°

Embodiment 3

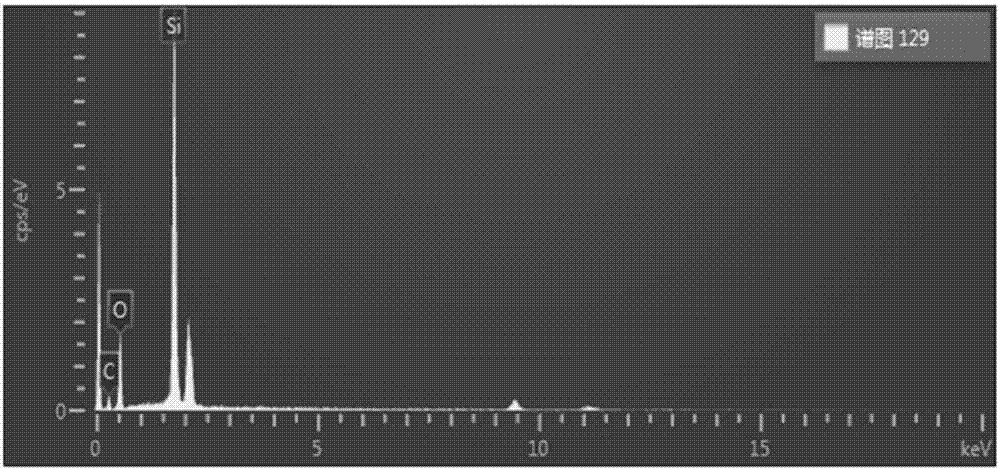

[0029] Add 80mL of deionized water into the reaction kettle equipped with a reflux device, add 4mL of acetic acid, stir evenly, add 1.2g of aqueous silica sol with a pH value of 9-10, and stir at 50-200rpm for 30 minutes. Increase the stirring speed to 500-2000rpm, and adjust the temperature of the water bath to 60°C, add 0.12g each of 0.5μm and 2μm silica powder, then stir at 50-200rpm for 30 minutes, and finally add 0.6mL tetraethyl orthosilicate, 0.6 mL of isobutyltrimethoxysilane, and stirred for 24 hours to obtain a water-based superhydrophobic coating with a micro-nano composite structure (without adding silicone or silicon-modified resin). image 3 Scan the spectroscopic image for the point of the coating. It can be seen from the figure that the coating mainly contains O, Si, and C elements, and does not contain F elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com