Multifunctional carpentery stuffing and its compounding process

A multi-functional, wood-based technology, applied in the field of adhesive fillers, can solve the problems of shortened pre-pressing time, single flour function, lower free formaldehyde content, etc., achieves improved cold adhesion fastness, improved finished product indicators, and is easy to popularize applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

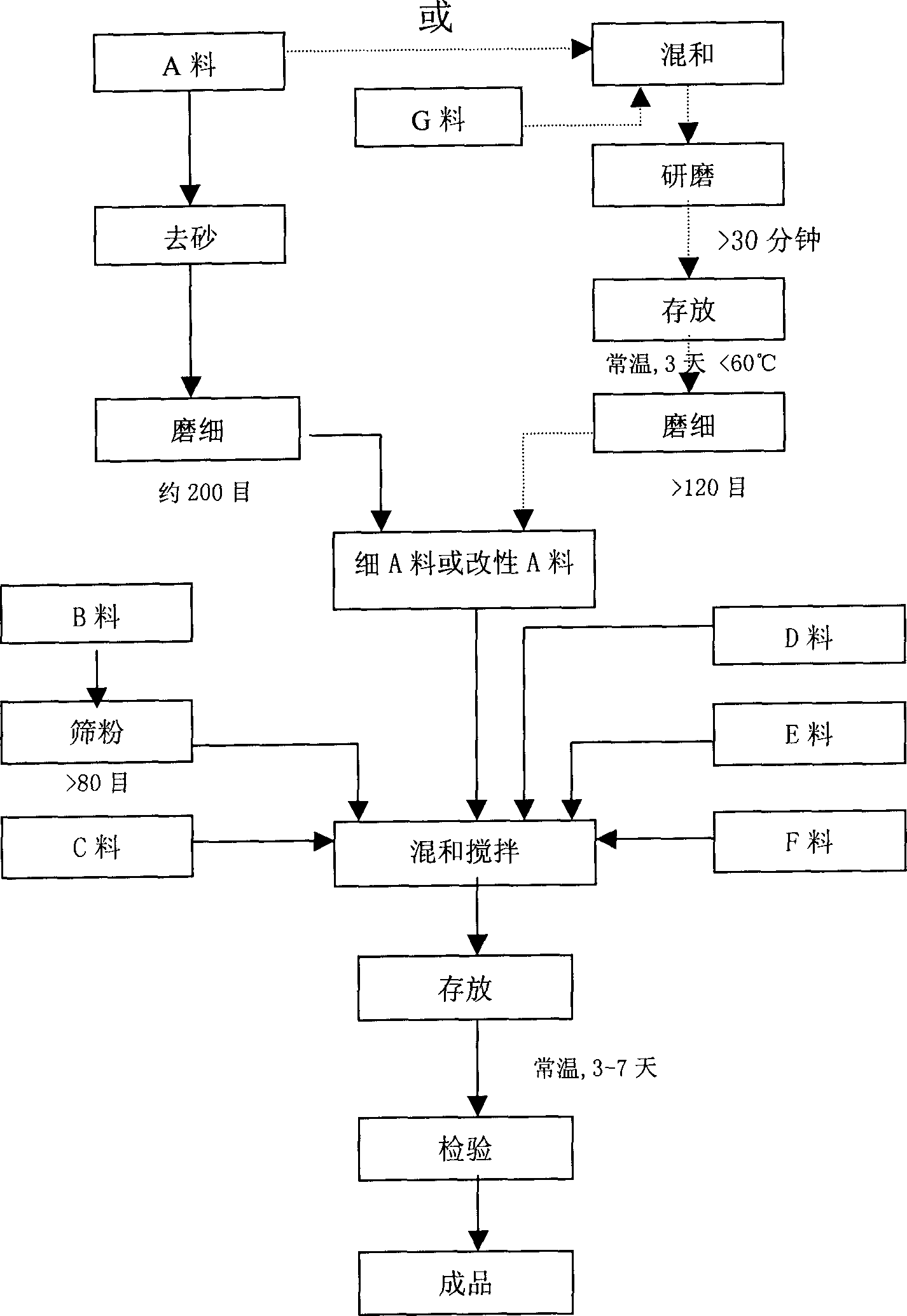

Method used

Image

Examples

Embodiment 1

[0036] Formula ratio: A material 72; B material 20; C material preferably carboxymethyl cellulose 4; D material 1; E material 2; F material preferably oxalic acid 1. Take the production of 1000kg filler as an example, the implementation method is as follows:

[0037] 1. Material A is desanded, dried, and ground to 200 mesh, and weighed 720kg for use;

[0038] 2. Material B is passed through a powder sieving machine to obtain a fine powder of more than 80 meshes, and 200kg of fine powder is weighed for later use.

[0039] 3. Transport material A, material B and other ingredients in the formula: 40kg carboxymethyl cellulose, 10kg melamine, 20kg urea, and 10kg oxalic acid to a high-speed rotary gravity-free mixer, shear and stir by the high-speed mixer Allow about 20-30 minutes to mix well.

[0040] 4. The mixed materials are naturally stored for 3-7 days, and the finished product is basically stable.

[0041] 5. The above formulas are all powder materials, and the fineness of...

Embodiment 2

[0043] Formula ratio: A material 70; B material 20; C material preferably carboxymethyl cellulose 2; D material 1.5; E material 2; F material preferably oxalic acid 3; G material preferably sodium carbonate: 1.5. Take the production of 1000kg filler as an example, the implementation method is as follows:

[0044] 1. Mix 700kg of material A with 15kg of material G, grind for about 30 minutes, store naturally for more than 3 days, fully carry out sodium modification, then dry and grind to make modified material A, with a fineness of more than 120 mesh .

[0045] 2. Material B is passed through a powder sieving machine to obtain a fine powder of more than 80 meshes, and weigh 200kg of the fine powder for later use.

[0046] 3. Transfer the modified A material, B material and other materials in the formula: sodium carboxymethyl cellulose 20kg, melamine 15kg, urea 20kg, oxalic acid 30kg, to a high-speed rotary gravity-free mixer, and then sheared by the high-speed mixer Cut and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com