Epoxy resin based neutron and gamma ray shielding composite material, as well as preparation method and application thereof

A technology of epoxy resin and composite materials, which is applied in the field of shielding materials, can solve the problems of difficulty in balancing the physical and mechanical properties of shielding performance, the inability to meet the requirements of shielding material application flexibility and construction diversity, and needs to be improved to achieve excellent shielding function , Excellent anti-mildew performance, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of the above-mentioned composite shielding material is: first mix the components evenly according to the composition, and then solidify and form (the temperature can be 25±2°C, the relative humidity can be 60±5%, and the time can be 24h), and the composite shielding material can be obtained. shielding material.

[0065] The epoxy resin mentioned in the present invention, fast neutron moderator, thermal neutron absorber, gamma ray shielding agent, inert diluent, active diluent, accelerator, auxiliary agent, lead sand and lead boron polymer Ethylene can also be obtained by means known to those skilled in the art, such as commercially available.

Embodiment 1

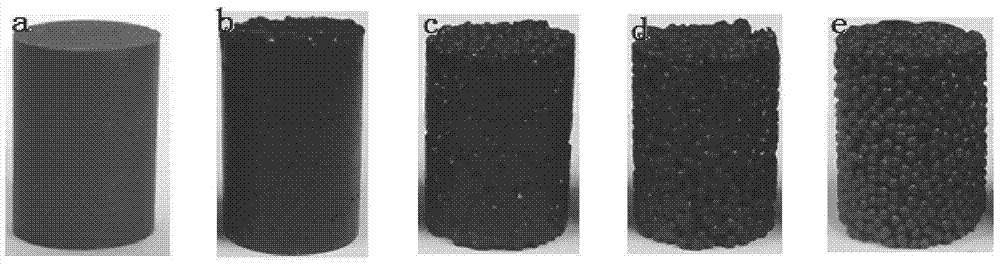

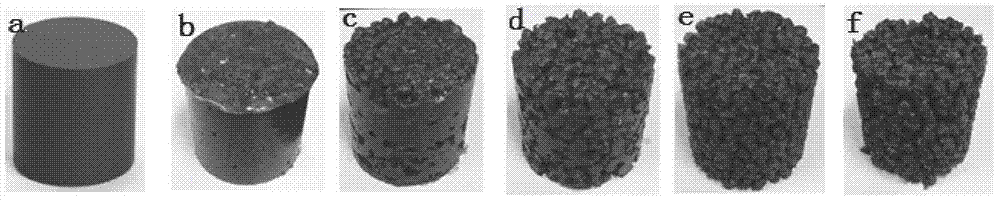

[0068] combine Figure 3-6 Illustrative Example 1

[0069] Step 1. Take raw materials according to the following ratio: 100g bisphenol A diglycidyl ether type epoxy resin E-51 (epoxy value 0.51), 60g modified isophorone diamine (amine value 260), 60g carbonized Boron (60μm particle size), 30g PE (200μm particle size), 900g lead powder (50-70μm), 10g benzyl alcohol, 10g cresol glycidyl ether, 5g phenol, 4.5g BYK-054, 7.0g BYK-9076, 10g KH-550;

[0070]Step 2. Add benzyl alcohol, cresol glycidyl ether, BYK-054, BYK-9076 and KH-550 into bisphenol A diglycidyl ether type epoxy resin E-51, and stir at a stirring speed above 500rpm Uniformly, the first mixture is obtained;

[0071] Step 3, mixing boron carbide, PE and lead powder evenly to obtain mixed powder;

[0072] Step 4, uniformly mixing the modified isophorone diamine and phenol to obtain a second mixture;

[0073] Step 5. Under continuous stirring (above 500rpm), divide the mixed powder three times, add 500g for the fir...

Embodiment 2

[0081] Step 1, take raw materials according to the following ratio: 100g bisphenol A diglycidyl ether type epoxy resin E-51 (epoxy value 0.51), 60g modified N-aminoethylpiperazine (amine value 270), 20g Boron carbide (particle size 10μm), 30g boron carbide (particle size 120μm), 30g PP (particle size 200μm), 1100g lead powder (50-70μm), 10g ethanol, 10g phenyl glycidyl ether, 5g salicylic acid, 5g BYK-054, 10g BYK-9076, 10g KH-550;

[0082] Step 2. Add ethanol, phenyl glycidyl ether, BYK-054, BYK-9076 and KH-550 into bisphenol A diglycidyl ether type epoxy resin E-51, and stir evenly at a stirring speed above 500rpm , to obtain the first mixture;

[0083] Step 3, mixing boron carbide, PP and lead powder evenly to obtain mixed powder;

[0084] Step 4, uniformly mixing the modified N-aminoethylpiperazine and salicylic acid to obtain a second mixture;

[0085] Step 5. Under continuous stirring (above 500rpm), divide the mixed powder three times, add 500g for the first time, 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com