Stepping linear motor

A linear motor and rotor shaft technology, applied in electrical components, electromechanical devices, propulsion systems, etc., can solve the problems of insufficient thread accuracy and poor concentricity, and achieve the effects of good concentricity, good versatility, and simple and reliable mold structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

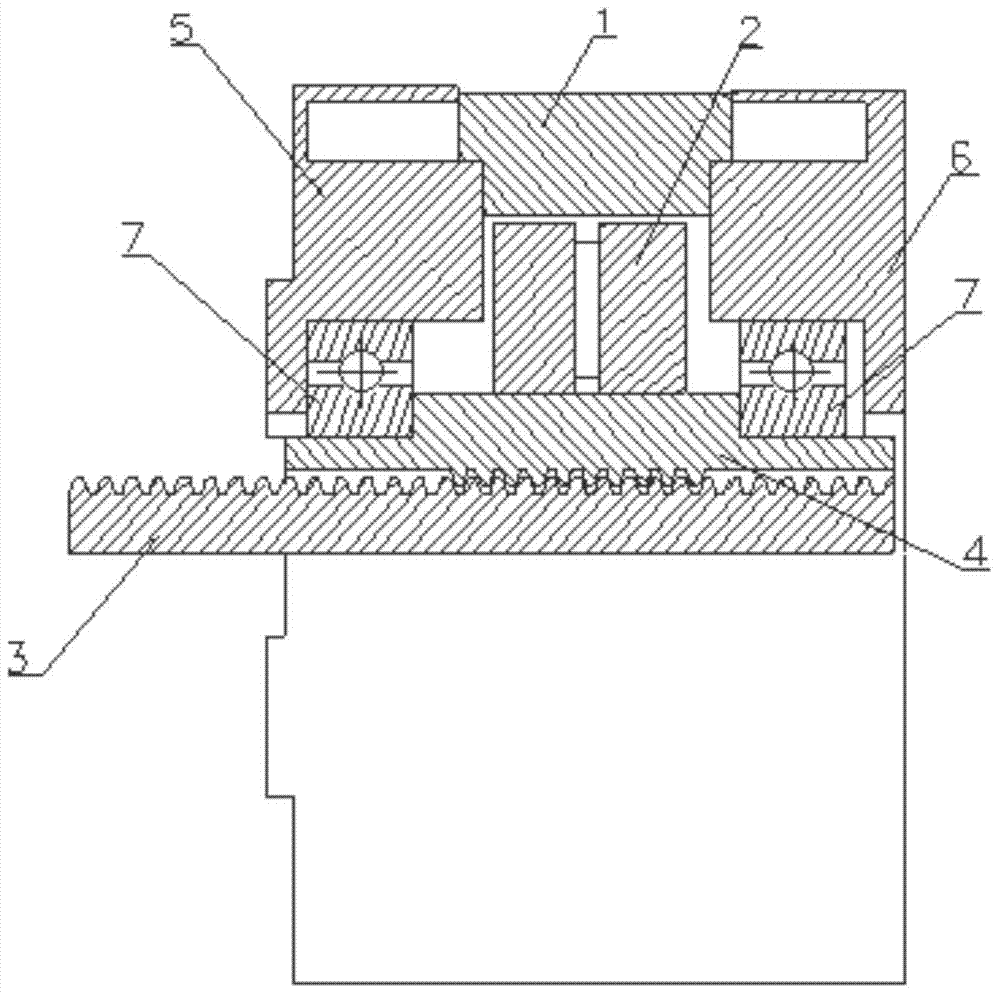

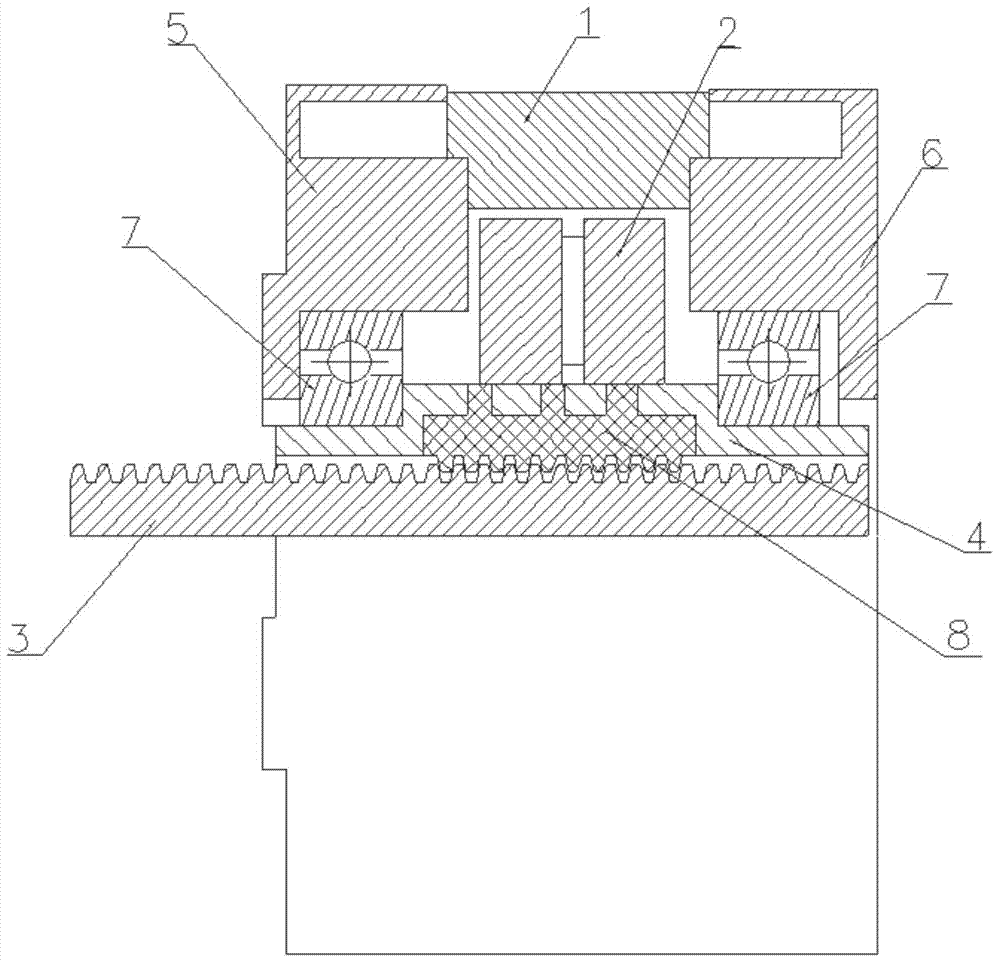

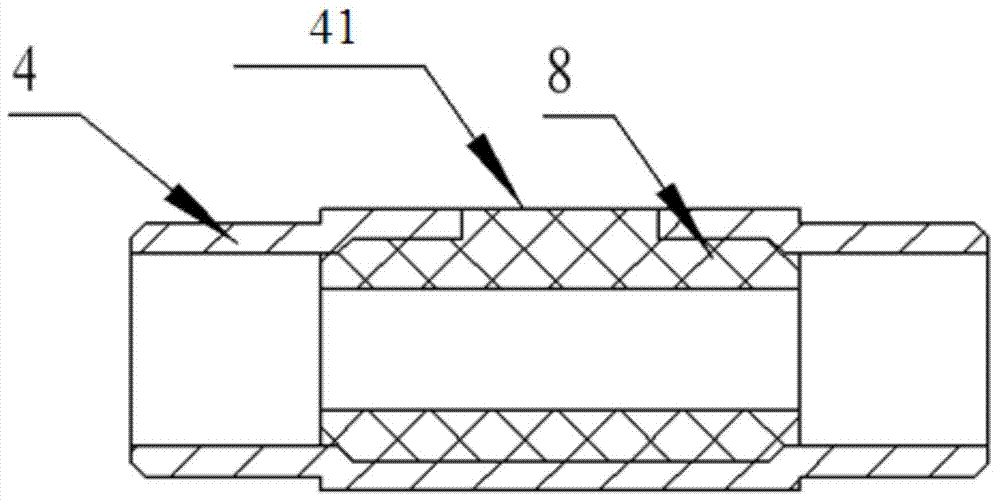

[0025] like Figure 2-4 As shown, a stepping linear motor includes a stator 1, a rotor 2, a screw 3, a rotor shaft 4, a left end cover 5, a right end cover 6, a bearing 7 and a plastic nut 8, and the screw 3 is connected to the rotor shaft 4 in transmission , the rotor shaft 4 is in transmission connection with the rotor 2, the bearings 7 are arranged at both ends of the rotor shaft 4, the left end cover 5 and the right end cover 6 are respectively arranged at both ends of the stator 1 and surround the rotor 2, and the described The plastic nut 8 is provided with threads matching the screw rod 3, and the screw rod 3 is connected with the plastic nut 8 and extends into the inside of the rotor shaft 4. The rotor shaft 4 is a hollow structure, which is used as an injection molding blank and injected into the hollow shaft.

[0026] The side of the rotor shaft 4 is provided with a through hole for fixing the plastic nut 8 . The manufacturing process of the plastic nut 8 is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com