High-transparence composite and manufacturing method thereof

A composite material and transparent technology, applied in the field of plastic materials, can solve the problems of high production cost and the need to further improve the transparency effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

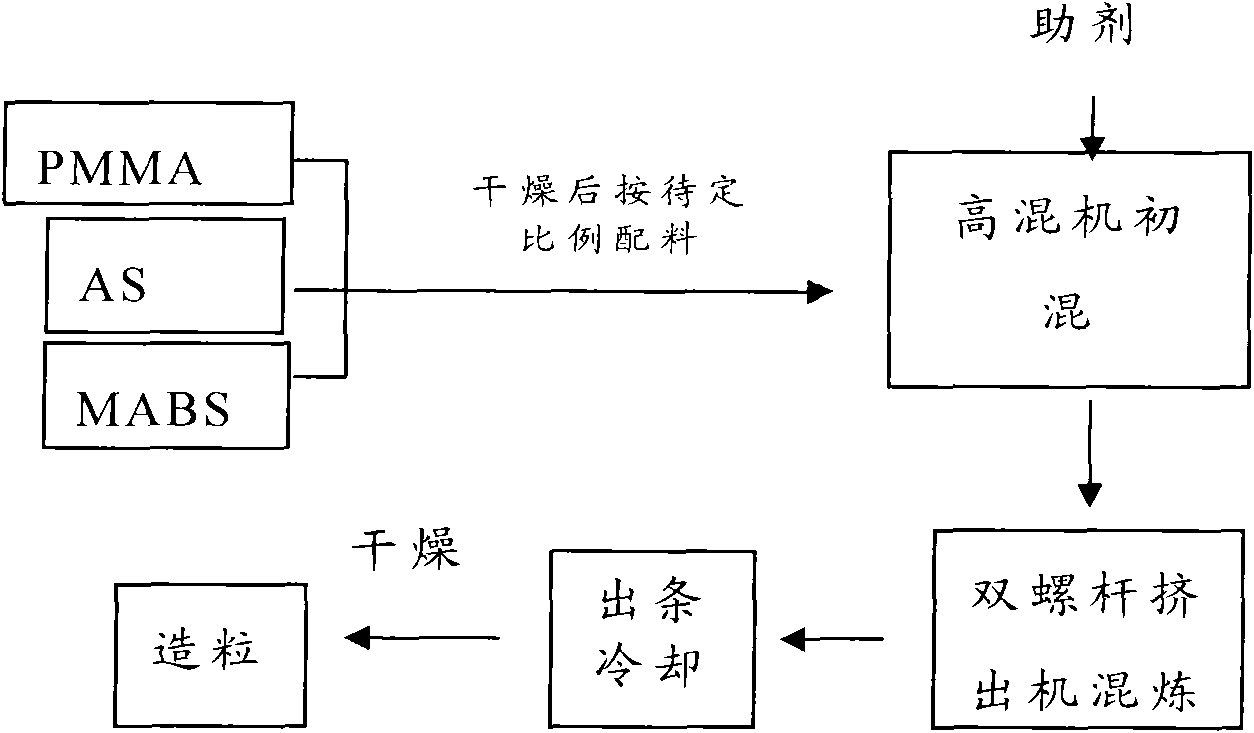

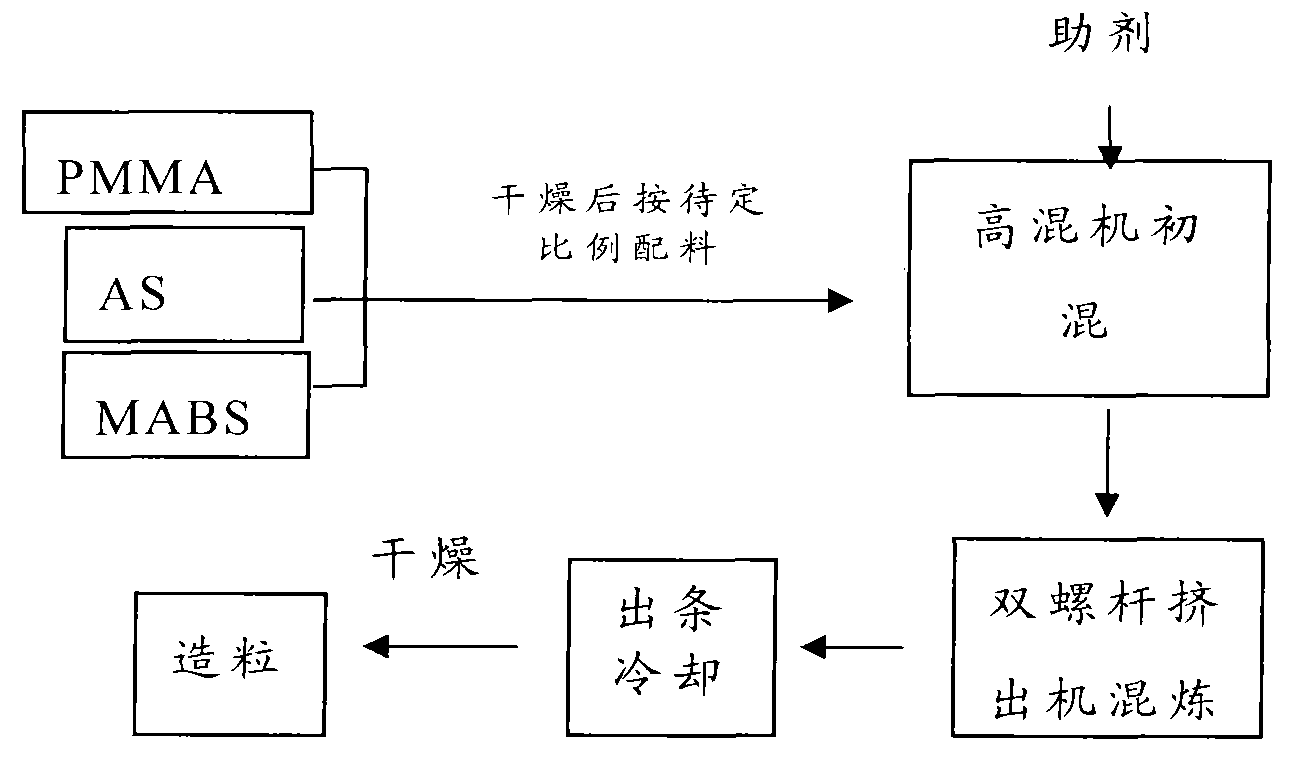

Method used

Image

Examples

Embodiment 1

[0024] 35 parts of PMMA, 40 parts of AS, 25 parts of MABS, 0.5 parts of polyvinyl alcohol, 0.2 parts of sodium lauryl sulfate, 4 parts of n-dodecyl mercaptan, and 0.8 parts of PEG 400DS.

Embodiment 2

[0026] 37 parts of PMMA, 37 parts of AS, 26 parts of MABS, 0.5 parts of polyvinyl alcohol, 0.15 parts of sodium methylene dinaphthalene sulfonate, 5 parts of n-dodecyl mercaptan, and 0.8 parts of PEG 400DS.

Embodiment 3

[0028] 40 parts of PMMA, 40 parts of AS, 20 parts of MABS, 0.5 parts of polyvinyl alcohol, 0.1 parts of sodium dodecylbenzenesulfonate, 4 parts of n-dodecyl mercaptan, and 0.8 parts of PEG 400D S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com