Plastic scintillator microsphere, preparation method and application

A technology for plastic scintillators and microspheres, which is applied in the preparation of microspheres, microcapsule preparations, instruments, etc., can solve the problems of limited application of liquid scintillation instruments, difficulties in waste liquid treatment and wastewater treatment centers, etc., and achieve good physical and chemical stability. high quality, low cost of raw materials, and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 100 mL of styrene into the separatory funnel, then add 100 mL of 5 mol / L NaOH solution, shake well, let stand for ten minutes, and release the lower aqueous phase. Repeat adding 100 ml of NaOH to wash twice, the upper liquid was distilled under reduced pressure at 75°C, and the colorless transparent distillate was collected as refined styrene solution.

[0026] Take 50 mL of styrene solution, add 1.00% PPO, 0.01% POPOP and 0.5% azobisisobutyronitrile, dissolve and shake well, store in the refrigerator for later use.

[0027] Take 1 L of deionized water, add 5 g of polyvinyl alcohol, stir to dissolve and set aside.

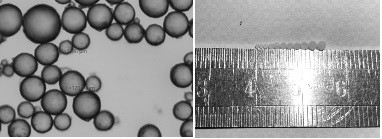

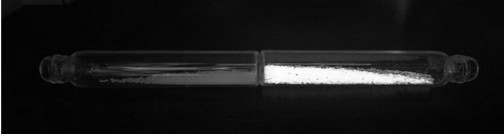

[0028] Take 10 mL of polyvinyl alcohol solution, add 140 mL of deionized water, add 5 mL of styrene solution, slowly raise the temperature to 82 °C, and keep it for 2 h. Then the temperature was raised to 90°C for 30 min to stop the reaction. The product was poured into a 500 mL beaker, washed several times with 80°C warm water, then washed with ethano...

Embodiment 2

[0030] Take 50 mL of vinyltoluene solution, add 1.00% PPO, 0.01% POPOP and 0.5% azobisisobutyronitrile, dissolve and shake well, store in the refrigerator for later use.

[0031] Take 1 L of deionized water, add 5 g of polyvinyl alcohol, stir to dissolve and set aside.

[0032] Take 10 mL of polyvinyl alcohol solution, add 140 mL of deionized water, add 5 mL of styrene solution, slowly raise the temperature to 82 °C, and keep it for 2 h. Then the temperature was raised to 90°C for 30 min to stop the reaction. The product was poured into a 500 mL beaker, washed several times with 80°C warm water, then washed with ethanol, filtered, and dried to obtain the product.

Embodiment 3

[0034] Put 100 mL of styrene into the separatory funnel, then add 100 mL of 5 mol / L NaOH solution, shake well, let stand for ten minutes, and release the lower aqueous phase. Repeat adding 100 ml of NaOH to wash twice, the upper liquid was distilled under reduced pressure at 75°C, and the colorless and transparent distillate was collected as refined styrene solution.

[0035] Take 50 mL of refined styrene solution, add 1.00% PPO, 0.01% POPOP and 1.0% azobisisobutyronitrile, dissolve and shake well, and store in the refrigerator for later use.

[0036] Take 1 L of deionized water, add 5 g of polyvinyl alcohol, stir to dissolve and set aside.

[0037] Take 10 mL of polyvinyl alcohol solution, add 140 mL of deionized water, add 5 mL of styrene solution, slowly raise the temperature to 82 °C, and keep it for 2 h. Then the temperature was raised to 90°C for 30 min to stop the reaction. The product was poured into a 500 mL beaker, washed several times with 80°C warm water, then wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com