Ultrahigh-density water-base drilling fluid and preparation method thereof

A water-based drilling fluid and ultra-high density technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult control of rheological properties, complex downhole, increased water loss, etc., to achieve timely The effect of clearing, increasing the capacity limit of solid phase, and increasing the density of base liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments.

[0021] Additives that need to be added during operation:

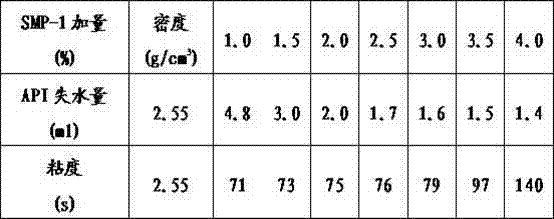

[0022] Due to the high solid content in ultra-high-density water-based drilling fluid, the huge specific surface area of solid particles greatly reduces the free water content of the entire system through wetting and adsorption, resulting in a decrease in the solid capacity limit of the system. Due to the intrusion of cuttings during drilling, the solid phase particles are easily connected to form a structure, which further increases the viscosity and shear force of the system. Therefore, when selecting ultra-high density water-based drilling fluid fluid loss control agent, it is necessary to consider While controlling the fluid loss, try not to affect the viscosity and shear force of the system, and even reduce the viscosity and shear force. At present, humic acid and sulfonated phenolic resin fluid loss control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com