Multifunctional true triaxial rock creepmeter

A technology of true triaxial and creep meter, which is applied in the field of experimental instruments, can solve the problems of insufficient experimental accuracy, increased test cost, and high instrument cost, and achieve the effects of comprehensive experimental functions, convenient load adjustment, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

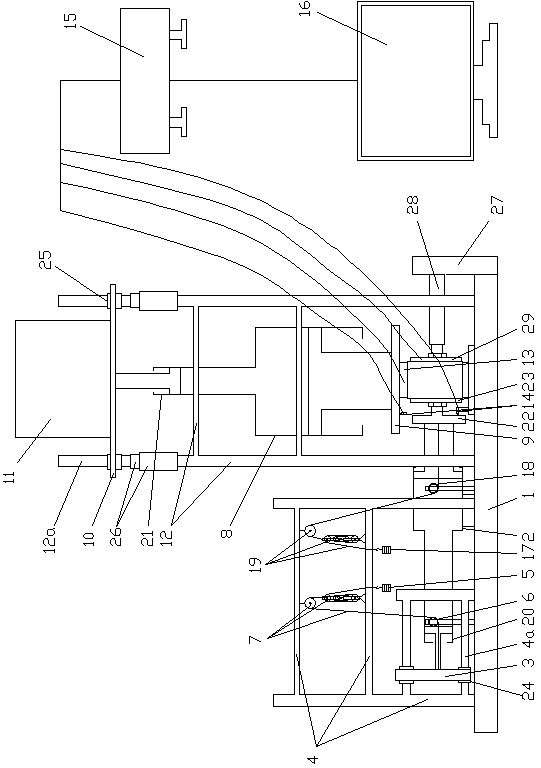

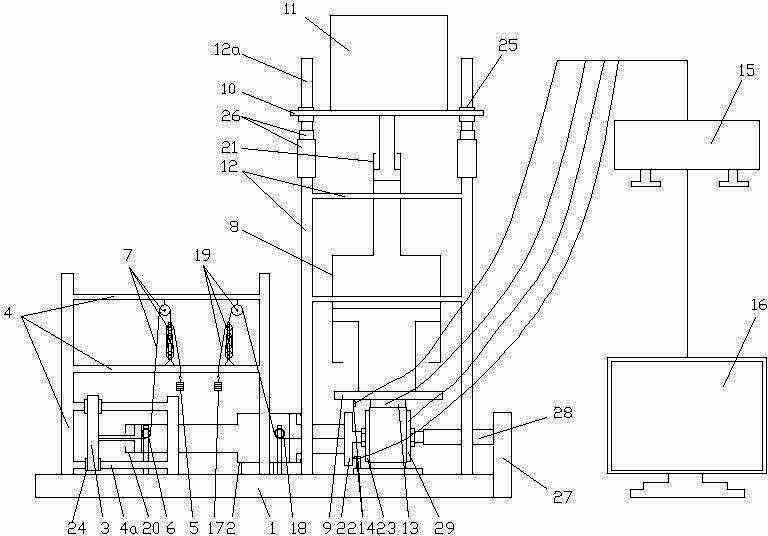

[0025] figure 1 It is a structural schematic diagram of the multifunctional true triaxial rock creep instrument of the present invention, figure 1 The horizontal stress loading system in only one direction is drawn in .

[0026] As shown in the figure, the multifunctional true triaxial rock creep instrument of this embodiment includes a base 1, a specimen mounting seat arranged on the base 1, two sets of horizontal stress loading systems and vertical stress loading systems with the same structure. and creep data measurement system, two sets of horizontal stress loading systems are arranged on the base in such a way that the test force directions are perpendicular to each other;

[0027] The stress loading system in the horizontal direction includes: the first oil cylinder 2 with the piston rod arranged horizontally, the first pressure loading plate 3 for transmitting pressure to the piston rod of the first oil cylinder 2, the first pressure loading plate 3 arranged at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com