Experimental system and method for water-gas two-phase seepage of gas-containing coal

An experimental system, gas coal technology, applied in the field of gas-containing coal water-gas two-phase seepage experimental system, can solve the problem of not overcoming the influence of liquid water on the seepage characteristics of coal, not considering the influence of liquid water seepage characteristics, liquid water and It is difficult to evenly mix the gas and other problems, and achieve the effect of low price, easy operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

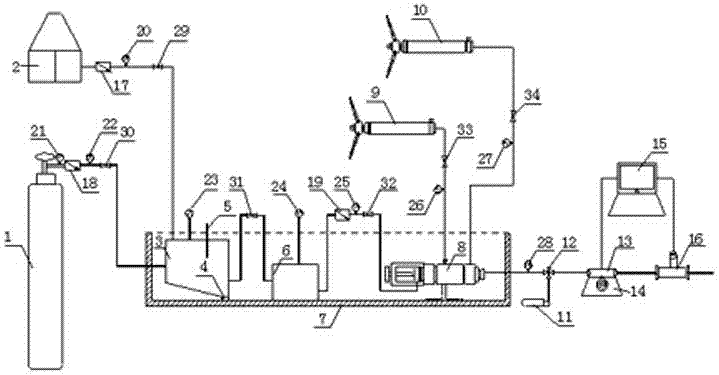

[0027] like figure 1 As shown, a gas-containing coal-water-gas two-phase seepage experimental system includes a gas mixing device, the gas mixing device includes a mixing tank 3 and an adsorption tank 6 connected in sequence, and the bottom of the mixing tank 3 is provided with a liquid collection Port 4; the inlet of the mixing tank 3 is respectively connected to the water vapor delivery pipeline and the high-pressure gas delivery pipeline; the adsorption tank 6 is connected to the air inlet of the coal sample holder 8, and the gas outlet of the coal sample holder 8 The pipeline is divided into a closed port and two branches through the four-way valve 12, one of which is connected to the vacuum pump 11, and the other is connected to the water vapor metering device and the gas flow meter 16 in sequence.

[0028] A steam generator 2, a first pressure reducing valve 17, a third pressure gauge 20, and a first switch 29 are sequentially arranged on the steam delivery pipeline; a h...

Embodiment approach

[0036] In this experiment, the water-gas two-phase adsorption, desorption, and seepage experiments of gas-containing coal are all carried out with water vapor instead of liquid water, which is a unique experimental method. Below mainly introduce the implementation method of the gas-containing coal-water-gas two-phase seepage experiment of the present invention, specifically describe as follows:

[0037] 1) Assemble the experimental system and test the tightness of the experimental system; specifically:

[0038] Close the first switch 29, the second switch 30, the fifth switch 33, the sixth switch 34, open the third switch 31, the fourth switch 32, connect the switch of the four-way valve 12 to the sealing port, open the second switch 30. After filling the pipeline with a certain pressure of gas, close the second switch 30, let it stand for 24 hours, and observe the fourth pressure gauge 23, the fifth pressure gauge 24, the sixth pressure gauge 25, the seventh pressure gauge 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com