Experimental device and method for rupture mechanical impact and vapor bubble migration of lead-based stack evaporator heat transfer tube

A heat transfer tube rupture and experimental device technology, which is applied in the field of research on the mechanical impact of heat transfer tube rupture and vapor bubble migration experimental devices in lead-based reactor evaporators. Simulate problems such as reactor core components, reaction vessels and visible windows to achieve the effects of enriching phenomena, broadening methods and ideas, and improving experimental functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

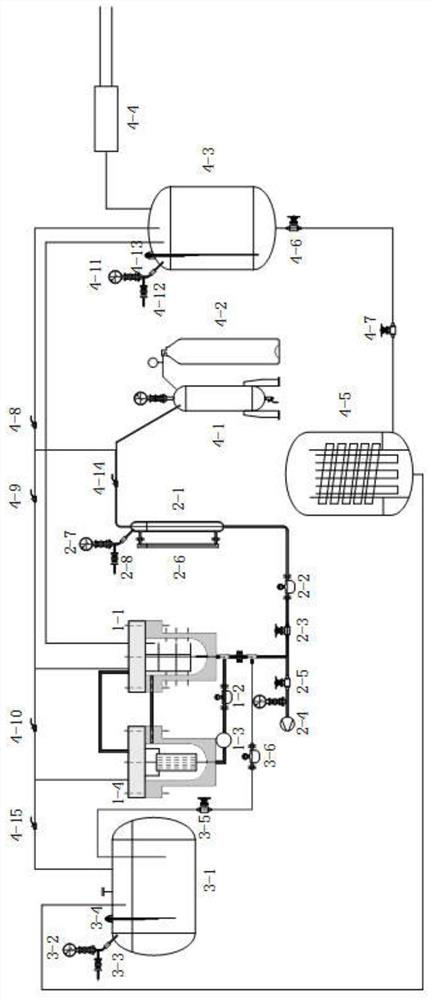

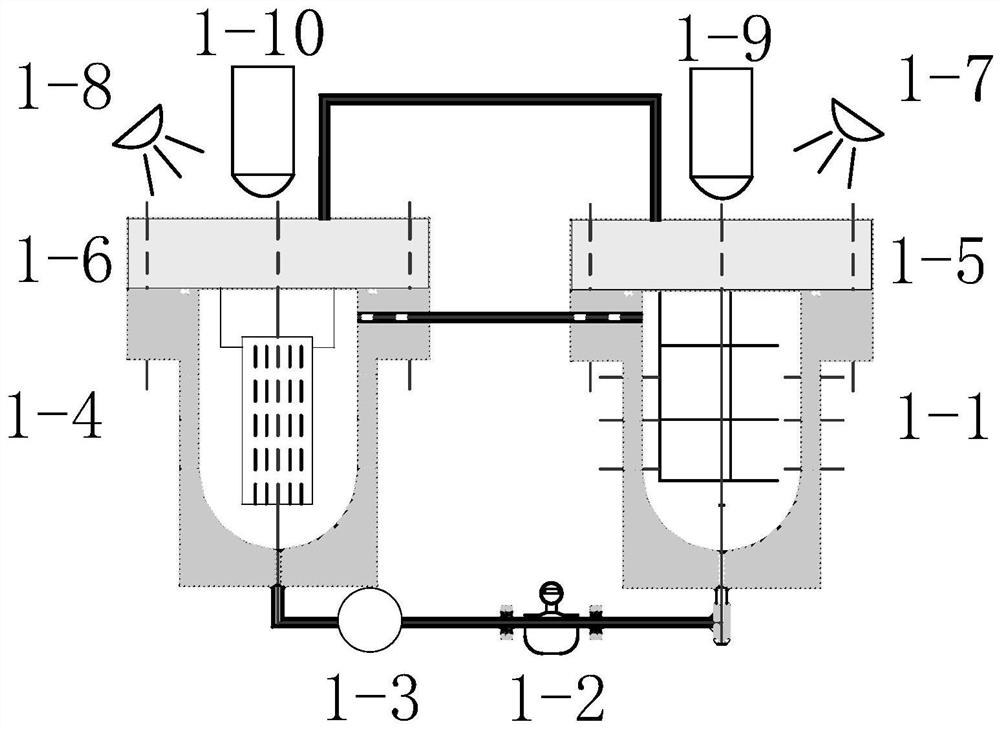

[0037] like figure 1 As shown, a kind of lead-based stack evaporator heat transfer tube rupture mechanical impact and bubble migration experimental device of the present invention comprises a first reaction vessel 1-1, a second reaction vessel 1-4, a high-pressure water vessel 2-1, a storage tank The experimental circuit composed of lead tank 3-1, argon buffer tank 4-1, lead discharge container 4-3, gas condenser 4-4, cold trap 4-5 and vacuum system 2-4.

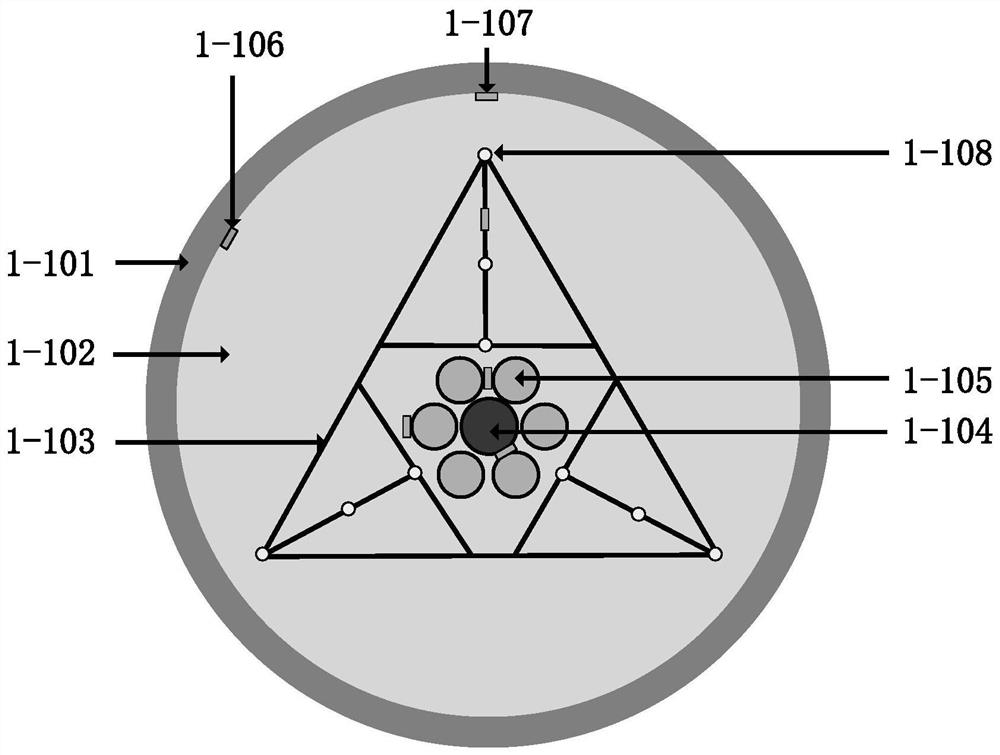

[0038] like figure 2 and image 3 As shown, the first reaction vessel 1-1 is a pressure vessel simulating the liquid lead-based alloy environment, the evaporator and the heat transfer tube bundle of the evaporator, and the first reaction vessel 1-1 is equipped with a first reaction vessel liquid lead Base alloy 1-102, pressure sensors 1-106 and high-temperature resistant strain gauges 1-107 are arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com