Square and round billet continuous casting meniscus electromagnetic stirring system and method with magnetic shielding and multi-mode

A technology of electromagnetic stirring and electromagnetic stirrer, which is applied in the field of conventional electromagnetic stirring of the mold and the meniscus electromagnetic stirring system of continuous casting of square and round billets, which can solve the problems of inability to remove inclusions, limited metallurgical effect of large cross-section square and round billets, and non-metallic inclusions. Problems such as limited control of the solidified shell in the initial stage of material cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing of embodiment:

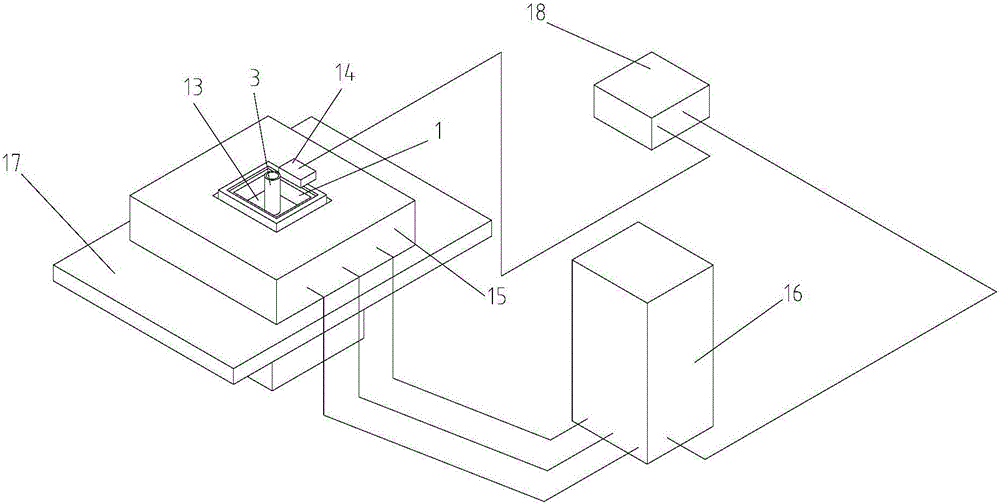

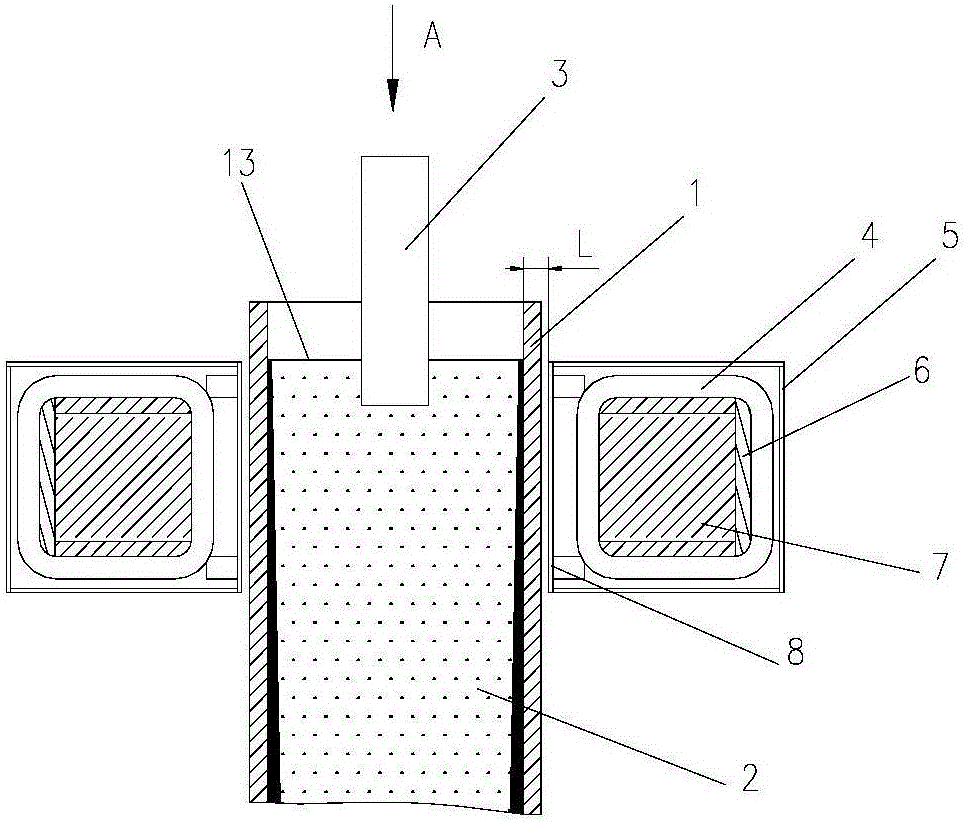

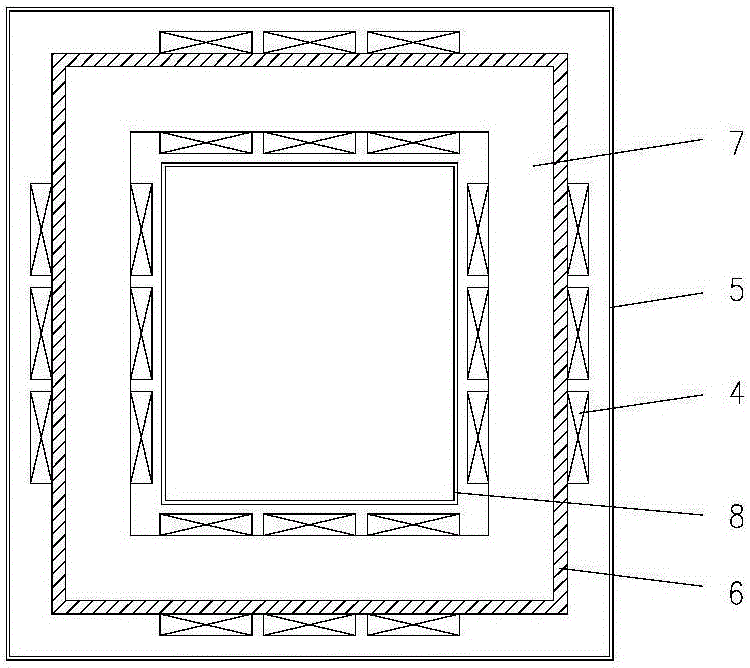

[0061] figure 1 Shown is the general diagram of the electromagnetic stirring system of square and round billet continuous casting meniscus with magnetic shielding and multi-mode in the present invention; figure 2 It is the ring form iron core structure and installation diagram of the present invention; image 3 yes figure 2 top view of

[0062] As shown in the figure, the present invention provides a square and round billet continuous casting meniscus electromagnetic stirring system with magnetic shielding and multi-mode, including meniscus electromagnetic stirrer 15, frequency conversion power supply control system 16 and mold electromagnetic liquid level detection system;

[0063] The meniscus electromagnetic stirrer is installed near the meniscus of the crystallizer 17;

[0064] The structural form of the crystallizer 17 is usu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com