Metal bipolar plate for proton exchange membrane fuel cell

A metal bipolar plate, proton exchange membrane technology, applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of complex design and cumbersome structure, and achieve simple processing, low processing cost, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

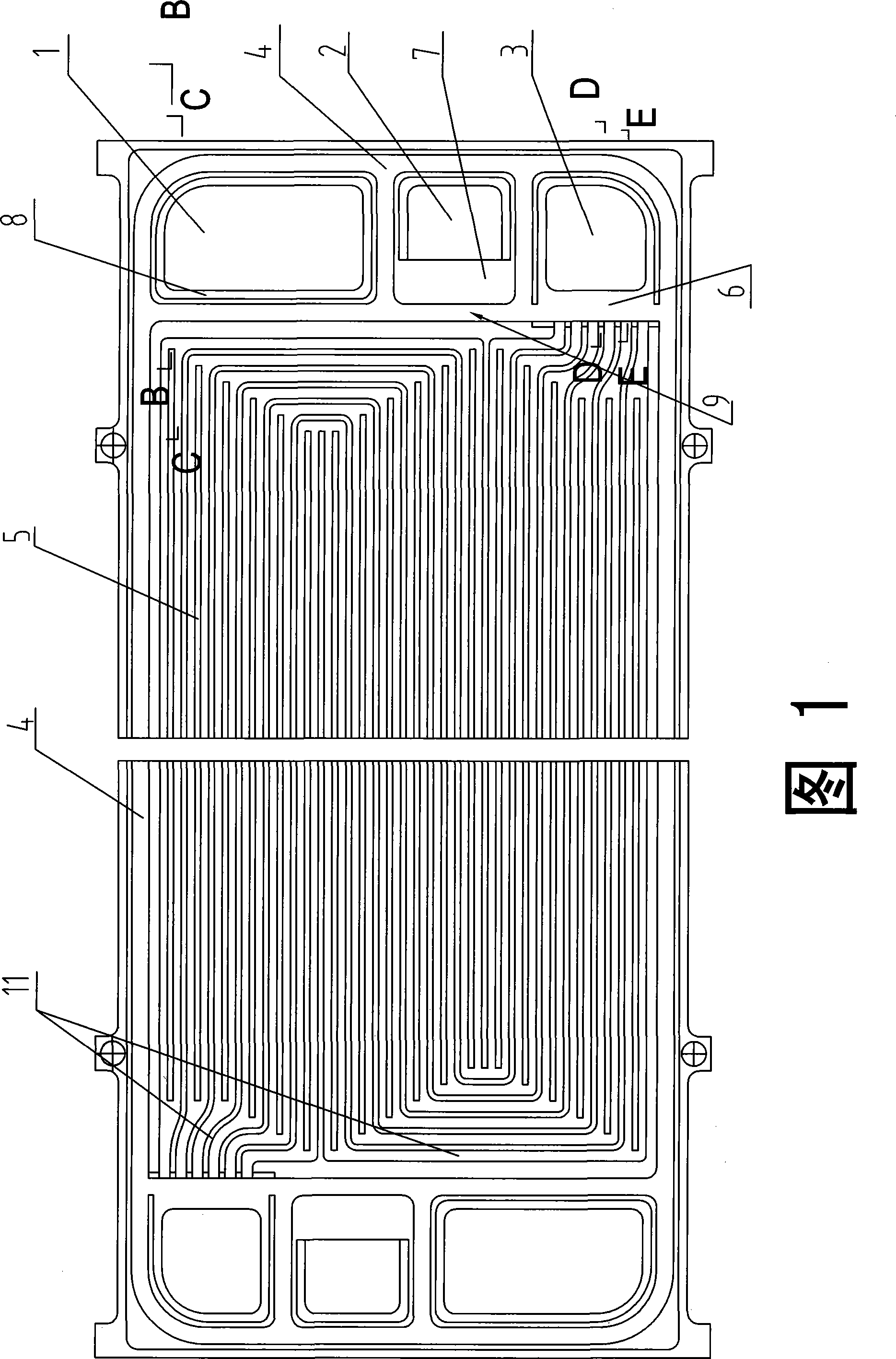

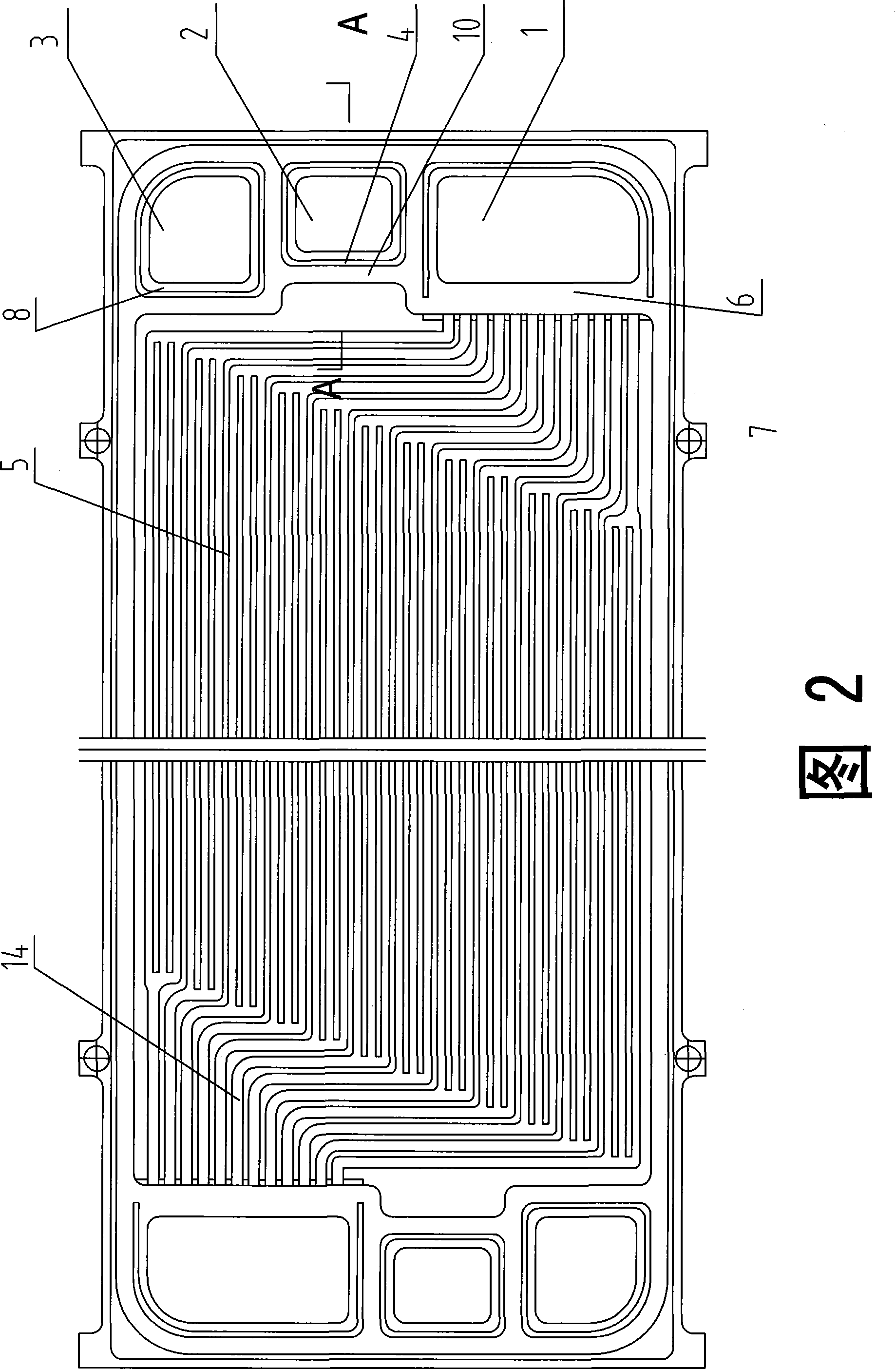

[0027] Example 1: Process steps:

[0028] According to the polar plate structure design molding die of the present invention;

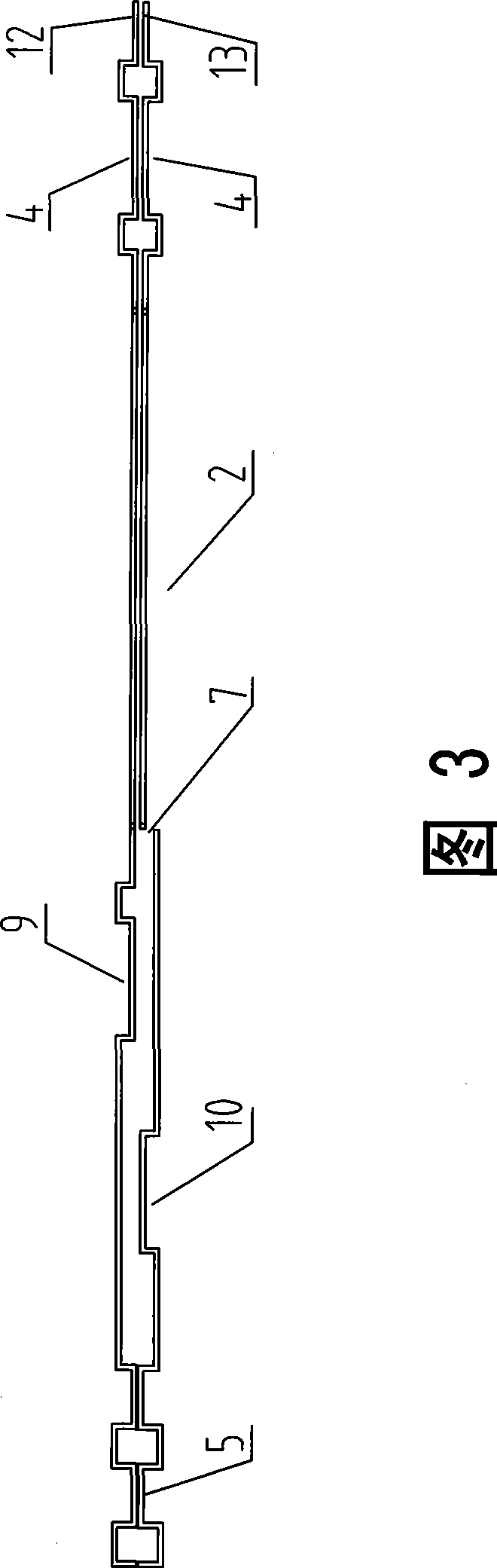

[0029] The surface of the stainless steel sheet with a thickness of 0.10mm is coated with volatile stamping and stretching oil, the plate is put into the mold, and molded on a four-column hydraulic press to obtain the designed flow field grooves of each cavity and the sealant groove plate, stamping grooves The depth is 0.5mm, the plate size is 410 x 100mm, and the flow field size is 340 x 85mm.

[0030] After the stainless steel is punched, the surface is treated with a corrosion-resistant conductive coating. This plan uses electroplating precious metal silver, and the total thickness of the coating is 0.02mm.

[0031] Lay small pieces of glass cloth laminated boards on the glue line slots of the cooling cavity of the cathode and anode plates respectively, the distance between the small pieces is 5mm, and the front and rear small pieces are aligned t...

example 2

[0036] Changing the thickness of the stainless steel plate in Example 1 to 1.5mm, the same process steps can obtain a bipolar plate with the same flow field design, and the thickness of the bipolar plate is 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com