Non-refrigeration infrared detector and preparation method thereof

An uncooled infrared and detector technology, used in electrical radiation detectors, semiconductor devices, final product manufacturing, etc. The effect of preventing the possibility, simplifying the process, and improving the efficiency of infrared absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

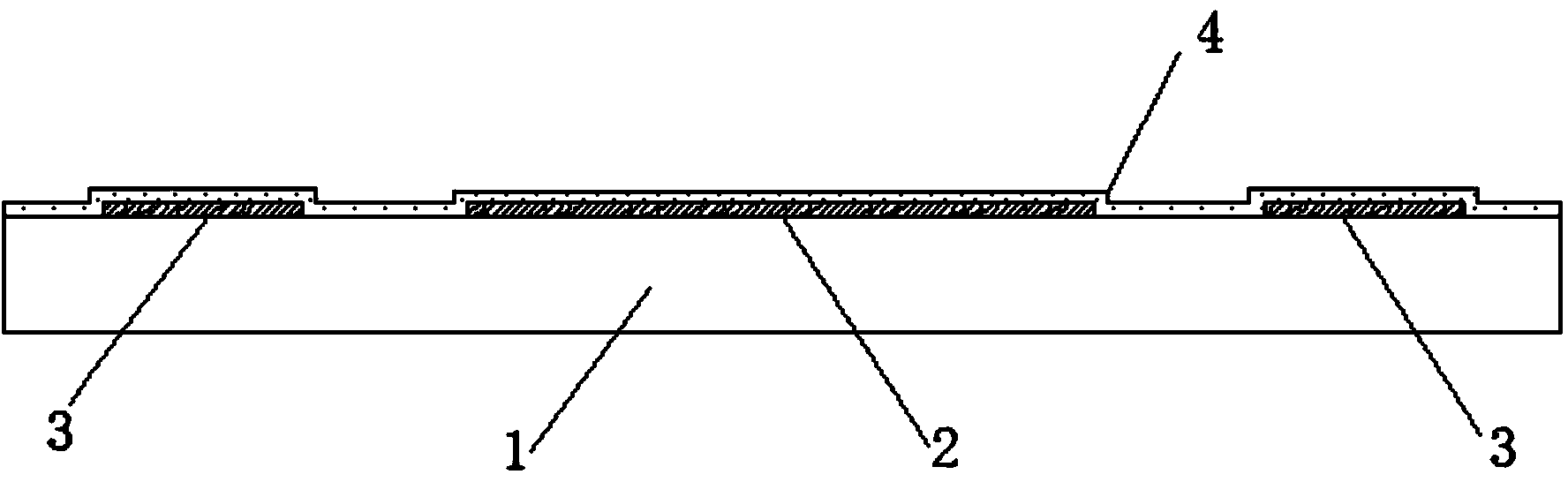

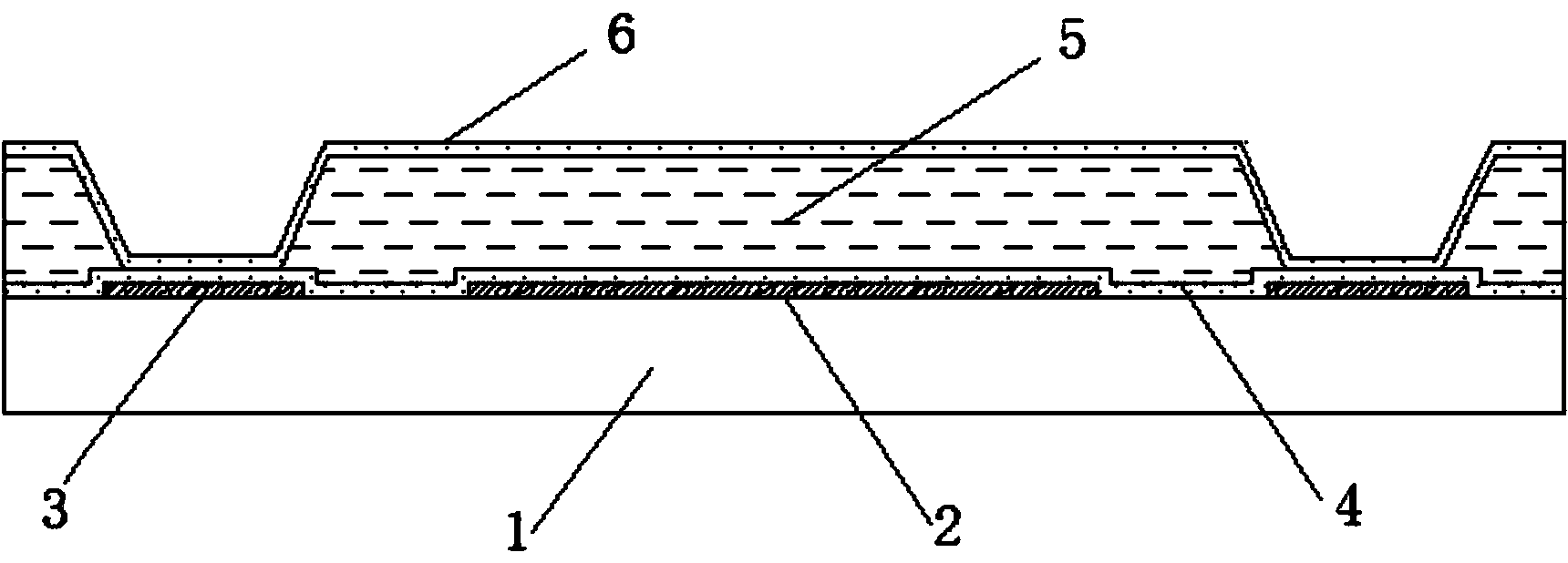

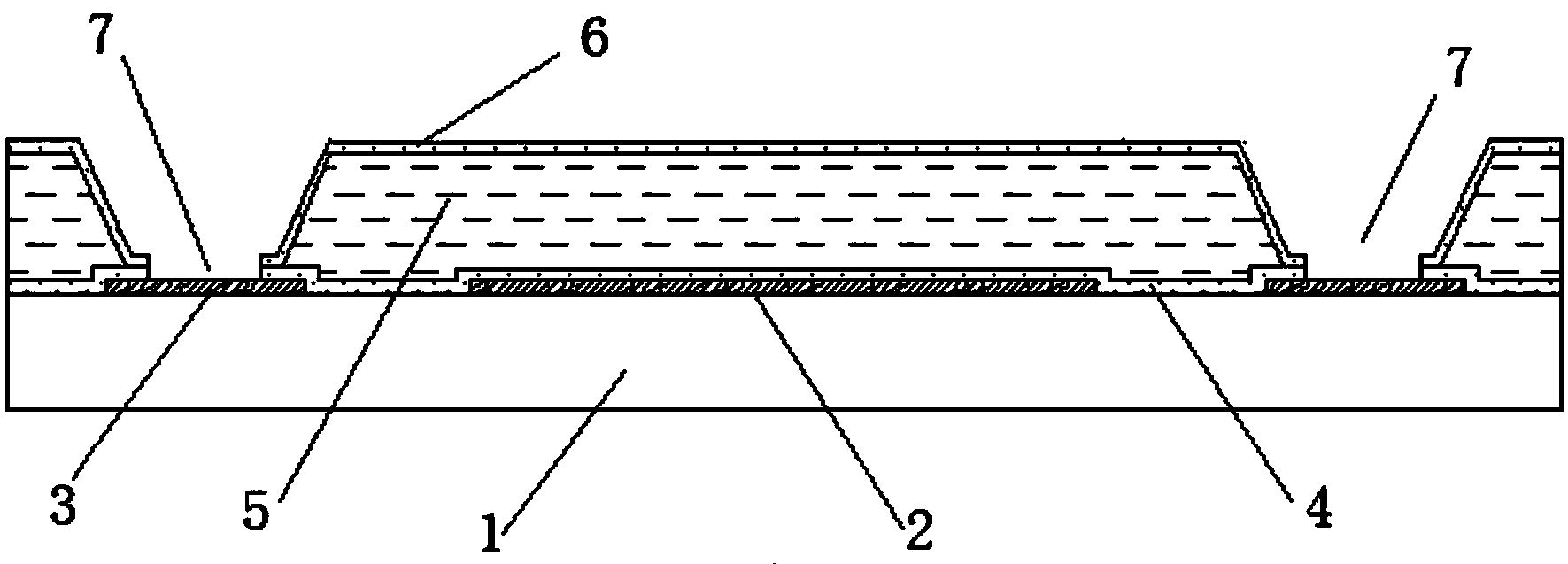

[0058] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0059] The present invention proposes a new method for preparing an uncooled infrared detector, that is, the patterning of the metal electrode layer is completed first to form a metal electrode, and then the protective layer is deposited, the contact hole is etched, and the heat-sensitive film is deposited again; because the metal electrode is formed first, Making the contact hole with the heat-sensitive film on the metal electrode can expand the size of the contact hole to the edge of the pixel, increase the filling factor of the pixel, reduce the difficulty of the process and reduce the contact resistance between the heat-sensitive film and the electrode, and provide more Lay the foundation for R&D and production o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com