Graphene sheet-carbon nanotube film composite structure and preparation method thereof

A carbon nanotube film and graphene sheet technology is applied in the field of graphene sheet-carbon nanotube film composite structure and preparation thereof, and can solve the problem of large contrast noise, amorphous carbon film thickness, and transmission electron microscope imaging resolution of nanoparticles. The improvement of the ratio has a great impact on the problems, so as to achieve the effect of small contrast noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

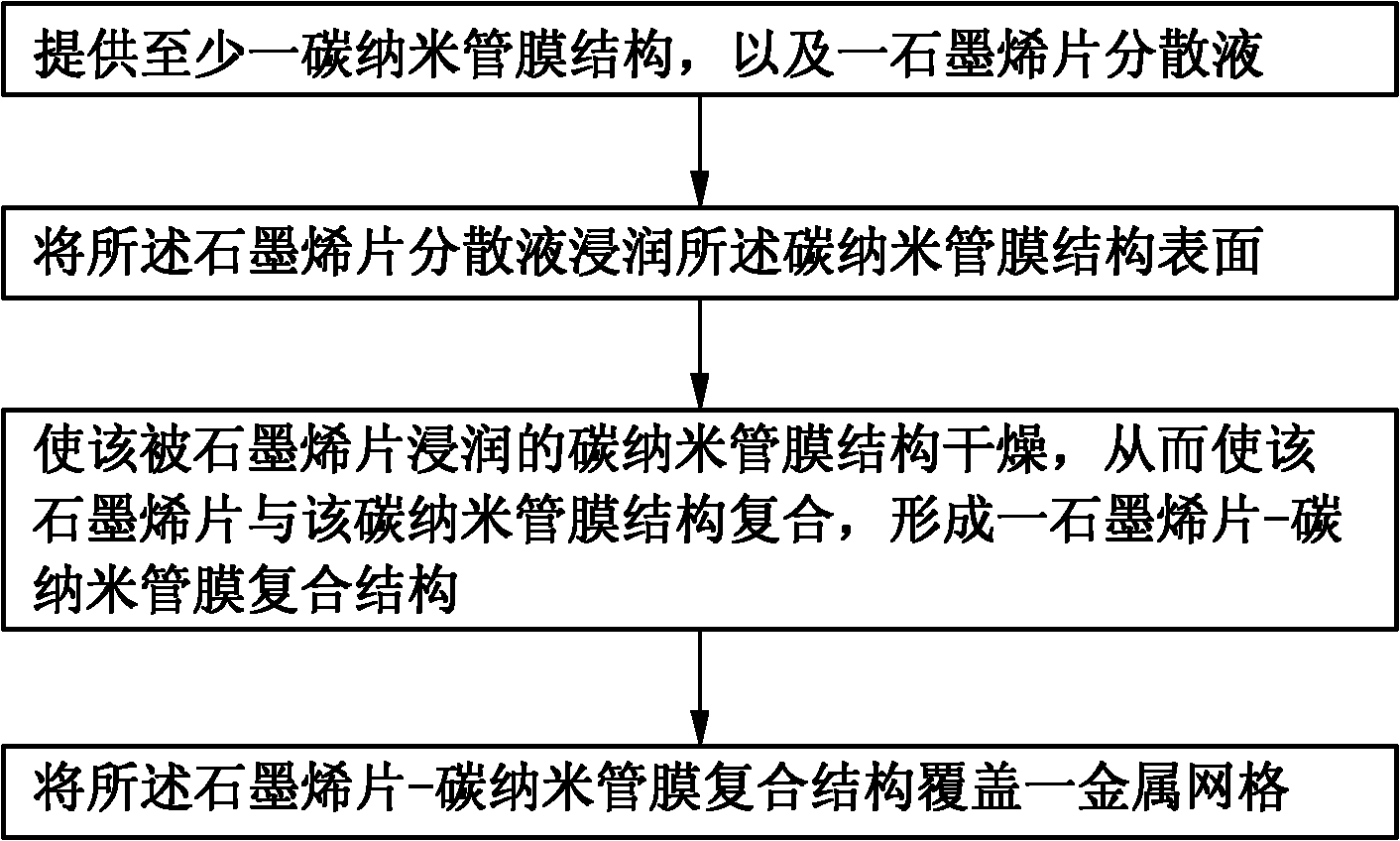

[0017] see figure 1 , the preparation method of the transmission electron microscope microgrid according to the first embodiment of the present invention mainly includes the following steps:

[0018] Step 1, providing a carbon nanotube film structure and a graphene sheet dispersion.

[0019] The carbon nanotube film structure includes multiple cross-stacked carbon nanotube films. The carbon nanotube film is obtained by directly pulling from a carbon nanotube array, and its preparation method specifically includes the following steps:

[0020] Firstly, a carbon nanotube array formed on a growth substrate is provided, and the array is a super-aligned carbon nanotube array.

[0021] The carbon nanotube array is prepared by a chemical vapor deposition method, and the carbon nanotube array is a pure carbon nanotube array formed by a plurality of carbon nanotubes that grow parallel to each other and perpendicular to the growth substrate. By controlling the growth conditions above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com