Nano-graphite alkenyl composite wave-absorbing material and method of preparing the same

A composite wave absorbing material and nano-graphene technology, which is applied in the field of wave absorbing materials and their preparation, can solve the problems of narrow interference band and high density, and achieve a wide electromagnetic attenuation band, low density, and excellent broadband wave absorbing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare the following 500ml electroplating solution with deionized water: NiSO 4 ·7H 2 O 200g.L -1 、NiCl 2 ·6H 2 O 20g.L -1 、KBr 1g.L -1 , MgSO 4 5g.L -1 、H 3 BO 3 30g.L -1 , Sodium allyl sulfonate 1.0g.L -1 . Adjust the pH of the plating solution to 5.

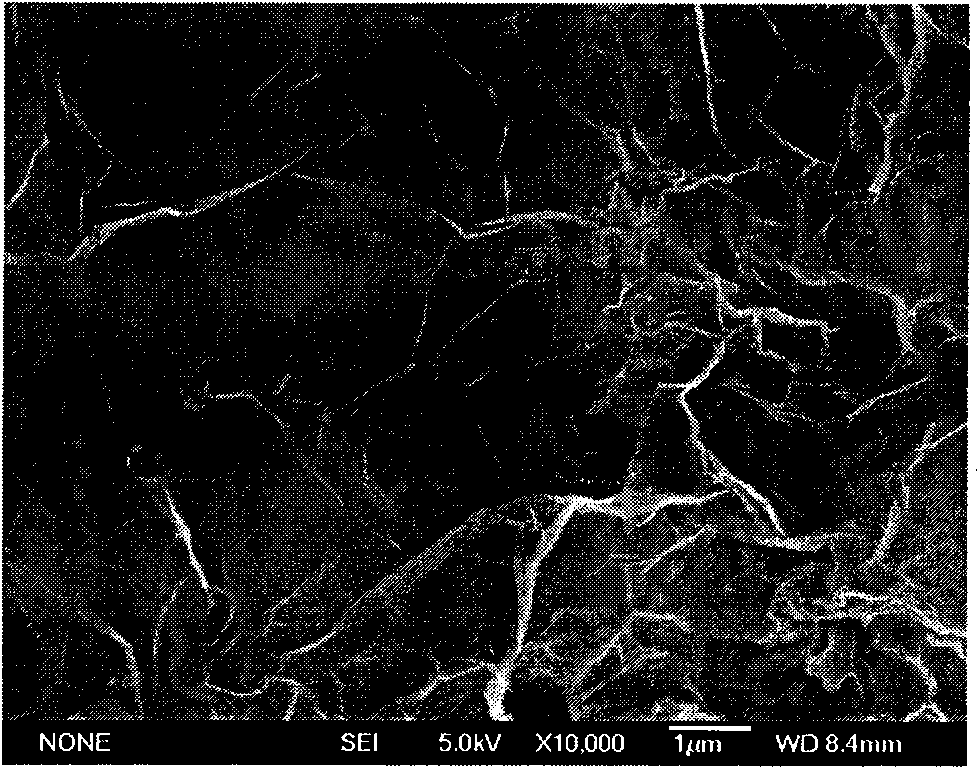

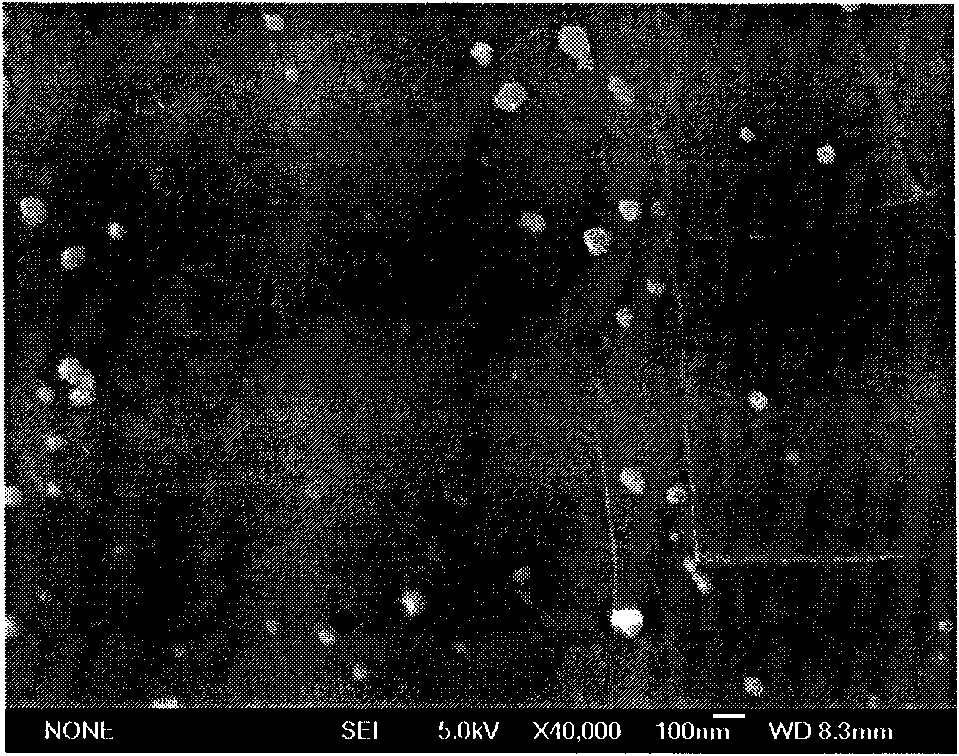

[0032] Weigh 1 g of graphene, adjust it into a slurry with 150 ml of electroplating solution, and disperse it ultrasonically for 30 minutes. The electroplating tank adopts an electroplating tank with the anode part and the cathode part separated. The graphene slurry is put into the anode part of the electroplating tank, and the remaining electroplating solution is poured into the cathode part of the electroplating tank. The anode is a nickel plate and the cathode collector is a carbon rod. . Turn on the upstream circulation stirring pump of the electroplating tank, start electroplating, the current density of electroplating is 5A·dm -2 , the electroplating time is 1 hour, and the electroplating temperat...

Embodiment 2

[0034] Prepare the following 500ml electroplating solution with deionized water: NiSO 4 ·7H 2 O 200g.L -1 、NiCl 2 ·6H 2 O 20g.L -1 、KBr 1g.L -1 , MgSO 4 5g.L -1 、H 3 BO 3 30g.L -1 , Sodium allyl sulfonate 1.0g.L -1 . Adjust the pH of the plating solution to 5.

[0035] Weigh 1 g of graphene, adjust it into a slurry with 150 ml of electroplating solution, and disperse it ultrasonically for 30 minutes. The electroplating tank adopts an electroplating tank with the anode part and the cathode part separated. The graphene slurry is put into the anode part of the electroplating tank, and the remaining electroplating solution is poured into the cathode part of the electroplating tank. The anode is a nickel plate and the cathode collector is a carbon rod. . Turn on the upstream circulation stirring pump of the electroplating tank, start electroplating, the current density of electroplating is 5A·dm -2, the electroplating time is 12 hours, and the electroplating temper...

Embodiment 3

[0037] Prepare the following 500ml electroplating solution with deionized water: NiSO 4 ·7H 2 O 400g.L -1 、NiCl 2 ·6H 2 O 20g.L -1 、KBr 1g.L -1 , MgSO 4 5g.L -1 、H 3 BO 3 30g.L -1 , Sodium allyl sulfonate 0.5g.L -1 . Adjust the pH of the plating solution to 5.

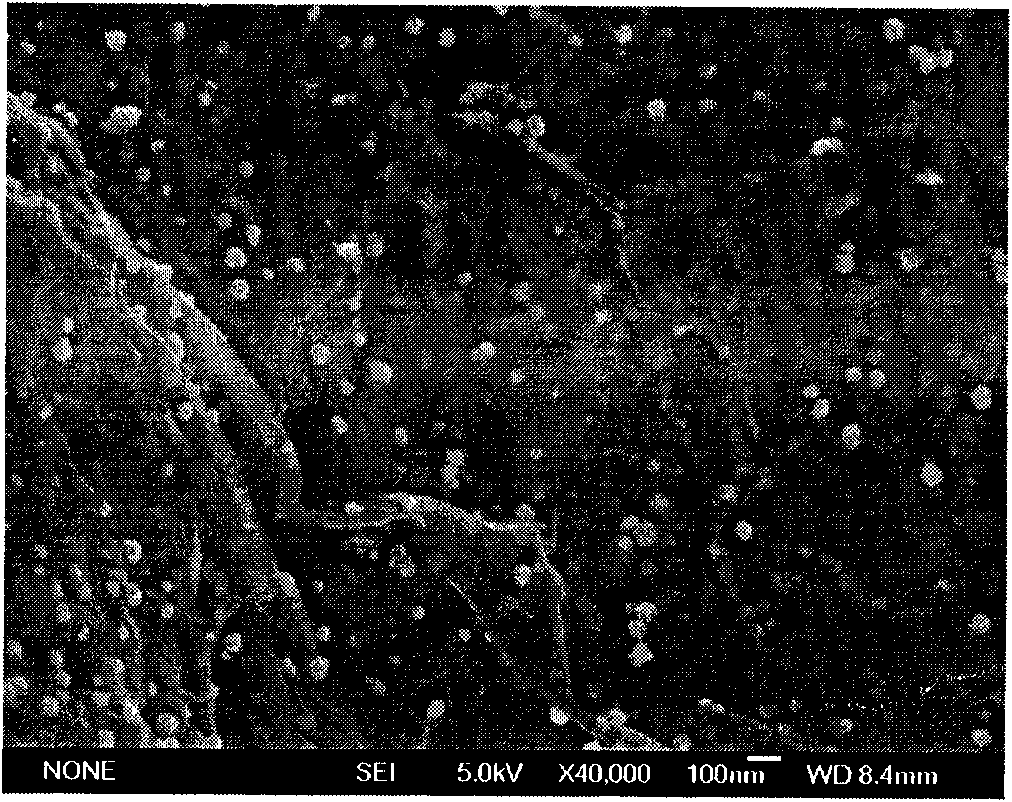

[0038] Weigh 1 g of graphene, adjust it into a slurry with 150 ml of electroplating solution, and disperse it ultrasonically for 30 minutes. The electroplating tank adopts an electroplating tank with the anode part and the cathode part separated. The graphene slurry is put into the anode part of the electroplating tank, and the remaining electroplating solution is poured into the cathode part of the electroplating tank. The anode is a nickel plate, and the cathode collector is a carbon rod. . Turn on the upstream circulation stirring pump of the electroplating tank, start electroplating, the current density of electroplating is 10A·dm -2 , the electroplating time is 15 hours, and the electroplating tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com